Disinfection with Lechler nozzles:

Good for your health

Disinfection is about neutralizing potentially harmful material harmless so that there is no longer any risk of infection from this material. Lechler nozzles make a decisive contribution here.

The most important facts in brief

Where is disinfection necessary?

Disinfection is necessary wherever germs, viruses or bacteria occur and where these germs, viruses or bacteria can cause damage. This applies, for example, in hospitals or doctors' surgeries, but also in food production or textile care and cleaning. Disinfectants are also indispensable in normal household use.

How is disinfection done?

During disinfection, the bacterial count is brought to an uncritical level by a suitable disinfectant. In addition to the choice of the right disinfectant, attention must also be paid to the correct performance and the exposure time of the disinfectant.

What must be observed?

Common disinfectants are for example peracetic acid, hydrogen peroxide, aldehydes, alcohols and - as known from indoor and outdoor swimming pools - chlorine. All these media are dangerous products, which is why careful and well-dosed use is strongly recommended. For the correct dosage it helps to atomize the media with nozzles.

Use of disinfection – Application examples

Disinfection and hygiene applications

- Hand disinfection

- Work equipment disinfection

- Sole and boot cleaning

- Room disinfection

- Disinfection of work sluices

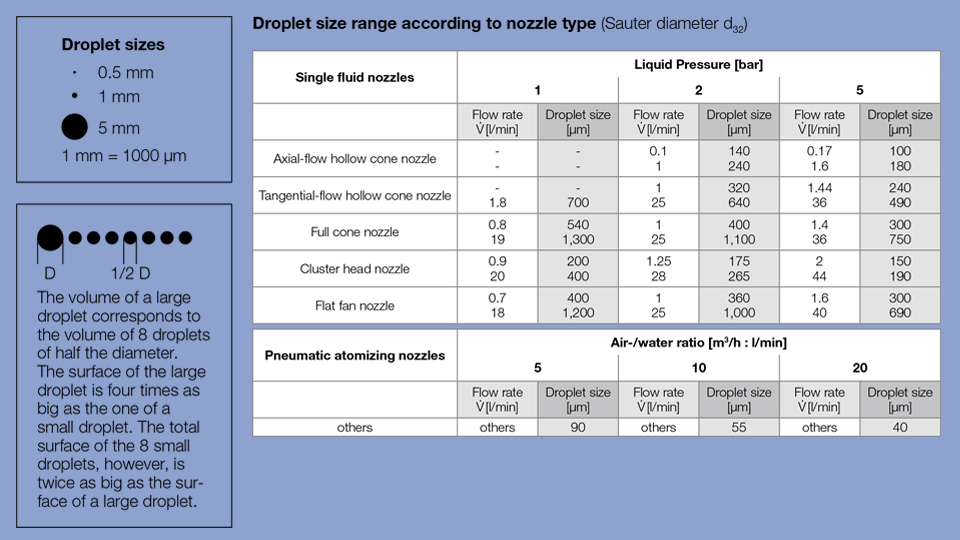

Why atomization?

Disinfectants should be atomized as finely as possible, since fine drops increase the reactive surface significantly.

Overview drop sizes and drop volumes

A large reactive surface is important to ensure that disinfectant is applied to each area and that the agent can act in a targeted manner. In addition, a large reactive surface helps to save medium, which reduces costs and is good for the environment.

Which nozzles can be used for disinfection?

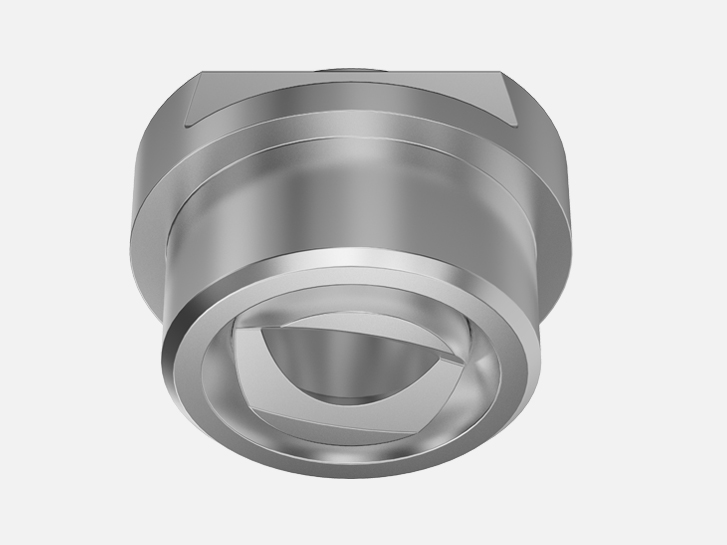

Single-fluid nozzles for disinfection

To generate the necessary fine droplets for a large reactive surface, hollow cone nozzles are classically used. Depending on the required volume flow and the surface to be disinfected, different capacity sizes can be used.

The Lechler series 220 and 214/216 made of high-quality stainless steel 1.4404 are particularly suitable for the atomization of disinfectants.

Fine atomization of smallest quantities

Series 220

Extremely fine, fog-like hollow cone spray.

- Spray angle: 60°, 80°

- V [l/min] (at p = 5 bar): 0.013 – 0.390

- Connection: 1/4 BSPP

If it may be a bit over

Series 214/216

Fine, uniform hollow cone spray.

- Spray angle: 60°, 80° (214); 60°, 90° (216)

- V [l/min] (at p = 2 bar): 0.08 – 0.32 (214); 0.40 – 8.50 (216)

- Connection: 1/8 BSPP (214); 3/8 BSPP (216)

Disinfection with impact – Nozzles for work equipment disinfection

Series 664/665

Automatic jet alignment due to dove-tail guide. Stable spray angle. Uniform, parabolic distribution of liquid. Spray pipes with these nozzles show an extremely uniform total liquid distribution.

- Spray angle: 20°, 30°, 45°, 60°, 75°, 90°,120°

- V [l/min] (at p = 2 bar): 6.30 – 63.00

- Connection: Assembly with 3/4 lock nut and dove-tail guide

Twin-fluid nozzles for disinfection

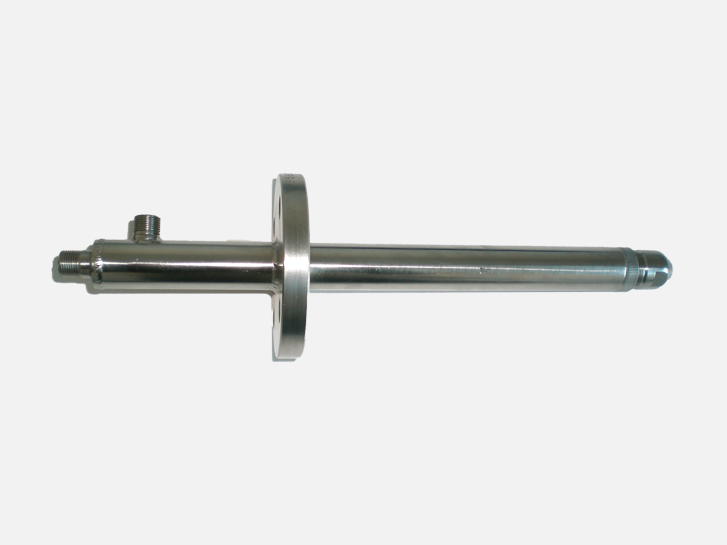

If the drops are really to be minimal, the use of two-substance nozzles is recommended. By using compressed air as atomizing medium, the liquid pressure can be kept low. Nevertheless, very fine drops and a large reactive surface are produced. In addition to surface disinfection, such nozzles can also be used for entire rooms.

For this purpose the Lechler series 136, 176 and the Lechler two-component atomizing lances are recommended.

Disinfection with flexibility

Series 136.4

Particularly fine flat fan atomization with air or gas.

- Spray angle: 45°, 60°, 80°

- V [l/min] (at p = 2 bar): 0.10 – 76.10

- Mixing of fluids: inside

- Mode of liquid supply: Pressure principle

Disinfection with flexibility

Series 136.5

Particularly fine flat fan atomization with air or gas.

- Spray angle: 60°

- V [l/min] (at p = 2 bar): 0.80 – 3.20

- Mixing of fluids: inside

- Mode of liquid supply: Siphon or gravity principle

Disinfection with flexibility

Series 136.6

Fine flat fan atomization with the aid of air or gas.

- Spray angle: 45°, 60°

- V [l/min] (at p = 2 bar): 1.70 – 102.10

- Mixing of fluids: outside

- Mode of liquid supply: Pressure principle

Disinfection with flexibility

Series 176 ViscoMist

Possibility of independent regulation of both atomizing air and fan air, which provides the user with infinite control over the viscous fluid’s spray pattern and droplet size.

- Spray angle: variable

- V Water [l/h]: 7.80 – 307.00

- Mixing of fluids: outside

- Mode of liquid supply: Pressure principle

Disinfection with flexibility

Lechler twin-fluid atomizing lances

Finest atomization, maximum reactive surface.