For flatness control in perfection:

SELECTOSPRAY

When rolling steel or non-ferrous metals, the roll gap profile is influenced by different factors. A decisive factor is the local thermal expansion of the work rolls. Perfect flatness is ensured by various flatness measurement methods with one indispensable actuator for shape control: zone-controlled roll cooling. Lechler SELECTOSPRAY Selective Roll Cooling Systems reliably correct asymmetrical strip shape defects and support work roll bending.

Benefits of Lechler SELECTOSPRAY Selective Roll Cooling Systems:

- Advanced design and engineering capabilities with more than 400 systems and 1,000 headers designed and manufactured.

- In depth application know-how and process knowledge.

- Comprehensive range of high-performance electrical, pneumatic and electro/pneumatic valves.

- In house design and build of dedicated control cabinets.

- Bespoke engineered systems as well as standard configurations.

- Global network of affiliated sales offices and representatives in over 40 countries, with production facilities in Germany, China, England, India, Hungary and the USA.

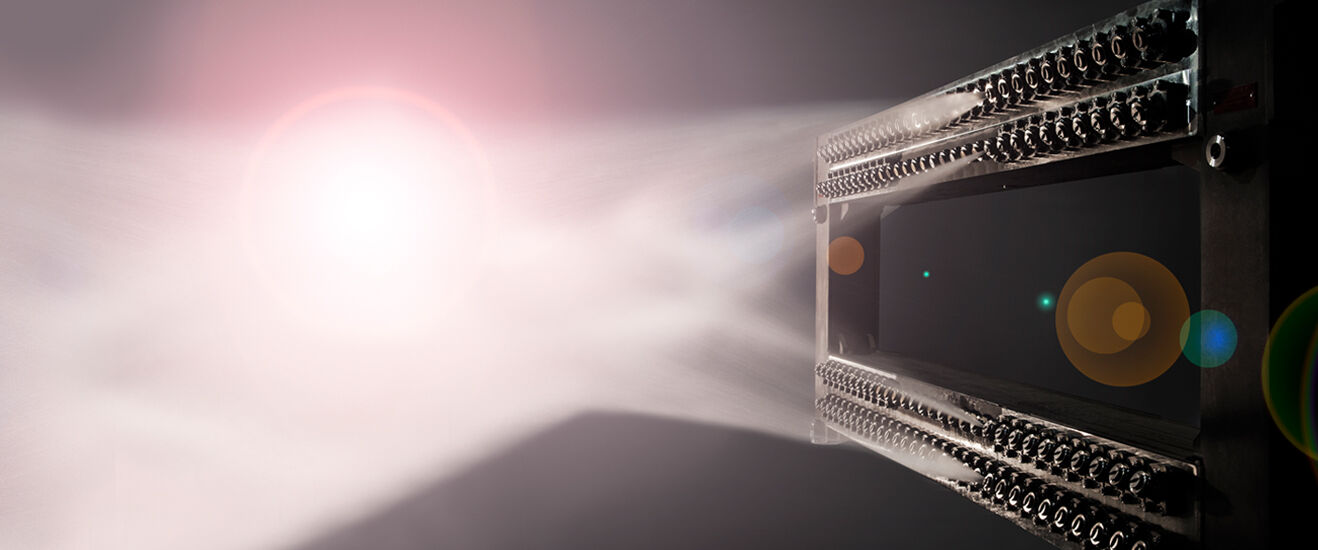

SELECTOSPRAY – Systems and valves for selective roll cooling

SELECTOSPRAY Header Technology

State of the art design and manufacture has seen Lechler headers develop from traditional multi-welded mild steel fabrications to current industry leading standards for conventional mill configurations using corrosion free, high strength stainless steel plates or heavier stainless steel forgings as used in Lechler's ultra-robust custom built solutions.

Lechler’s new generation of headers are designed and built to survive the most challenging rolling environment and designs incorporate features such as integral roll-change rails, HD protective front plates, and as a standard, extremely robust pneumatic and electrical connector blocks and mounting arrangements.

SELECTOSPRAY Valve Family

Selective roll cooling headers are fitted with the appropriate valve types from Lechler's family of valves. Valve type and design are carefully selected for optimum performance to give consistent and reliable spray control in each application.

SELECTOSPRAY Control Cabinets

Lechler control cabinets offer the customized control interface to drive pneumatic or electrical SELECTOSPRAY systems.

SELECTOSPRAY Control Hoses

The best valves in the world are only as good as the signal they are provided with and in the challenging environment of a rolling mill it is imperative that components do not deteriorate and can survive typical catastrophic mill events. Lechler provides ultra-robust hose solutions for pneumatic signals and electrical signals.