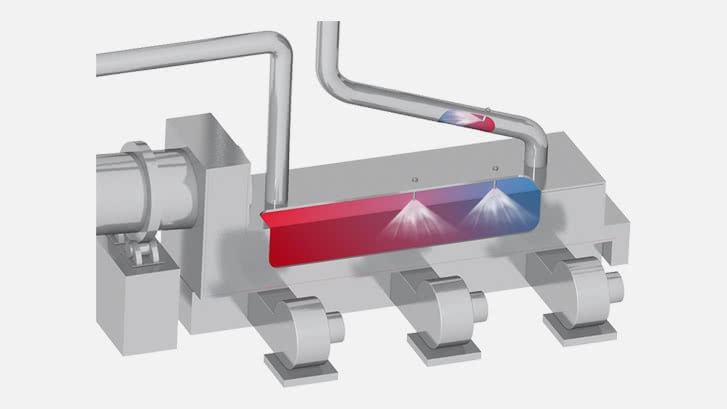

Gas cooling

Efficient and systematic cooling

Precise gas cooling of hot flue gases in cement plants, waste incineration plants and power plants creates stable conditions for safe and efficient operation of downstream plant components. Lechler offers gas cooling systems for various applications that can be individually adapted to customers’ requirements. Best results are achieved in gas cooling processes only when detailed knowledge of the process-specific requirements is available to assist in the choice of nozzles.

Gas cooling applications

Evaporative and chlorine-bypass cooler

Precise cooling and conditioning of hot flue gases creates stable outlet conditions for the safe and efficient operation of downstream plant components.

Downcomer Duct

Pre-cooling to protect downstream plant components and reduce the amount of operating gas.

Cyclone preheater

Injection for compensation of temperature peaks or additional cooling before the downcomer duct.

Clinker cooler

Gas cooling in or after the clinker cooler to optimize, protect and improve the efficiency of the downstream plant components.

Ball mill and roller mill

In the roller mill the injection of water stabilizes the grinding bed and optimizes the grinding process; in the ball mill injected water lowers the temperature in the mill.

Spray dryers

Spray drying is a process for disposing of residual and waste water and thus complying with the regulations of waste-water-free plants.

Corresponding products

Nozzle lances and systems for gas cooling

Efficient cooling and conditioning

Lechler nozzle lances and systems to generate the optimum droplet size range and distribute it as uniformly as possible in the gas flow.

References