Clinker cooler

System-optimizing, -protecting and efficiency-enhancing cooling.

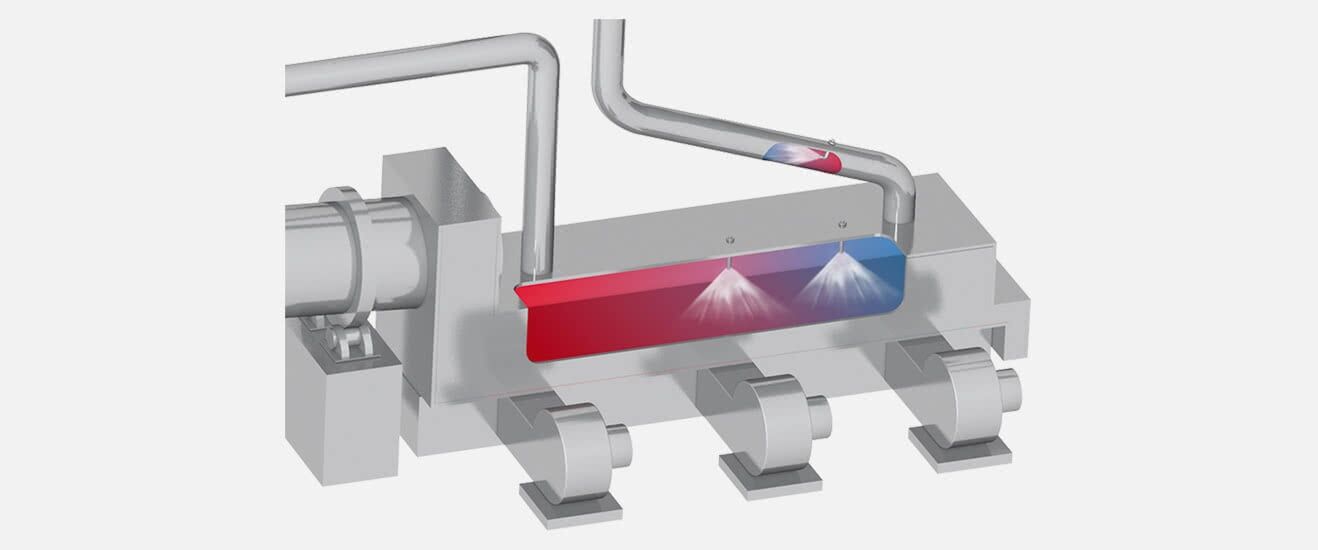

Following capacity increases, cooling with air alone is often no longer sufficient to achieve the proper operating conditions of the downstream filter. Injecting water into the clinker cooler provides a remedy here. The cooling of the gas also causes the gas volume to reduce and protects downstream plant components from excessive gas temperatures. This reduces operating costs and avoids additional investment costs for a larger filter.

Our solution

The injection takes place at the rear part of the clinker cooler, immediately upstream of the gas outlet. Depending on the space above the clinker cooler, the nozzles can be attached both on the top and the side. We usually offer spillback nozzles for controllability.

In comparrison to conventional single-fluid nozzles, spillback nozzles ensure consistently fine droplets over the entire control range.

In addition to direct injection into the clinker cooler, injection is also possible into the duct downstream of the clinker cooler. This requires a sufficiently long and straightrunning evaporation section.

Corresponding products

Nozzle lances and systems for gas cooling

Efficient cooling and conditioning

Lechler nozzle lances and systems to generate the optimum droplet size range and distribute it as uniformly as possible in the gas flow.

Professional reports