Focus topic: One stop shop for spray drying

Want it all? At once? Welcome to your one stop shop! At Lechler, manufacturers and operators of spray drying facilities are able to find nozzles for every application – from a single source.

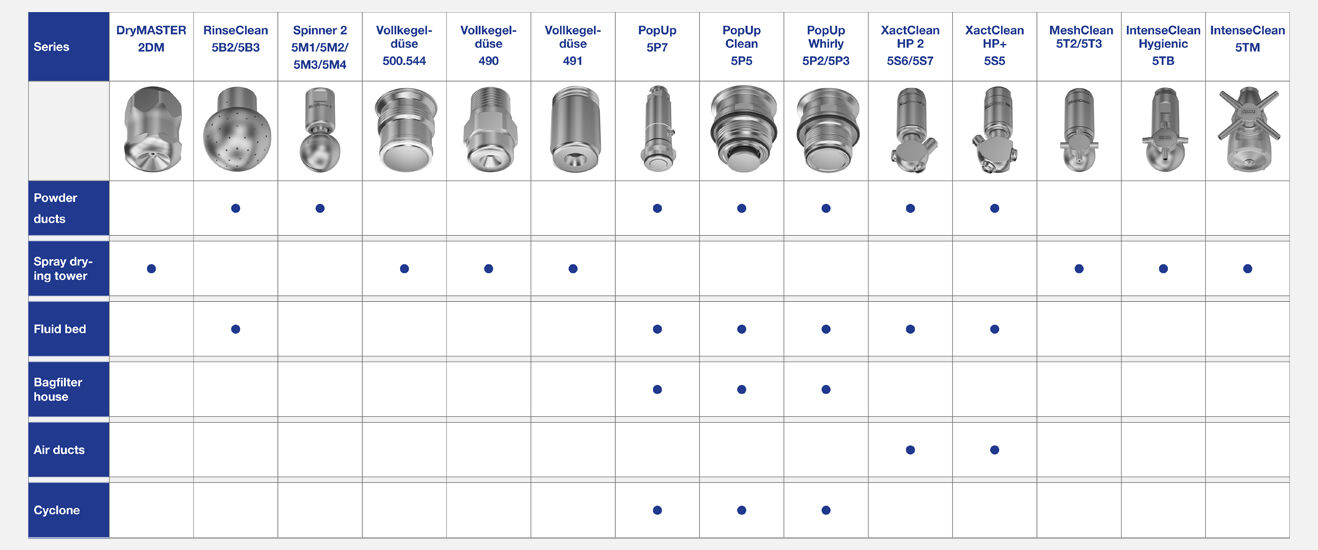

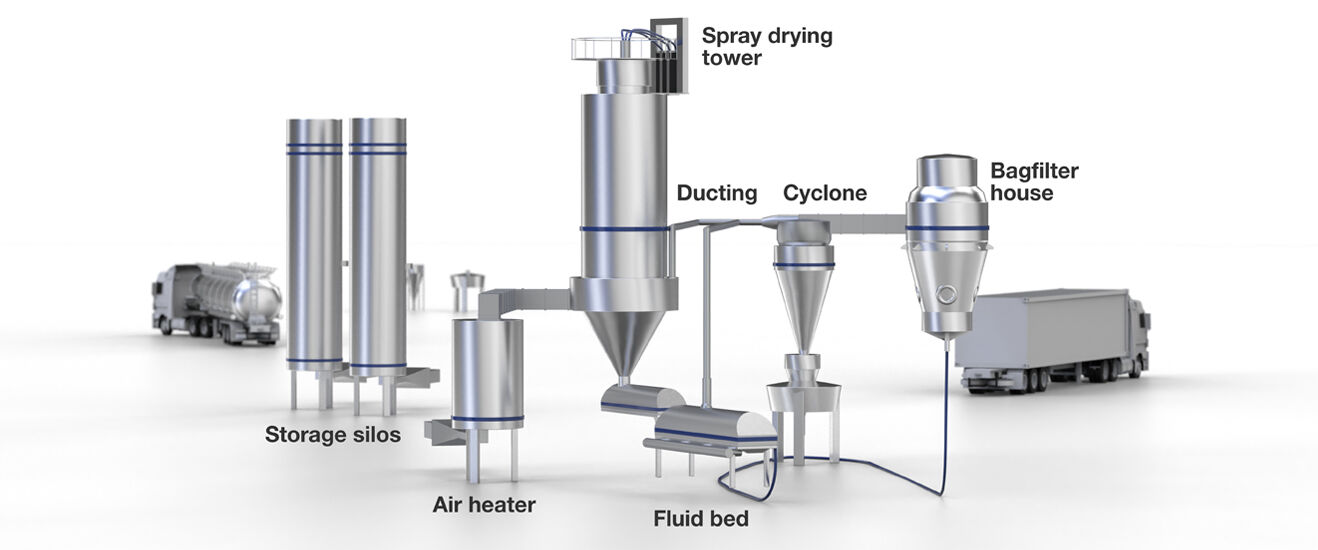

In a spray tower, fine atomized liquids are dried into a powder using hot air or gas. In this process, the powder quality is directly related to the nozzle technology used. In other areas of the spray drying process, final product quality and yield can be determined by the efficiency of cleaning in place. In the Lechler one stop shop, the correctly suited solution can be found for all nozzle applications within a spray drying plant.

As a solution provider for atomization tasks, Lechler supports you from the design and planning phase of a new processes, to improving an existing process using our superior spray technology. Covering all atomization tasks within a spray drying process using off the shelf or tailor made solutions, we also offer individual support in nozzle handling, training and maintenance.

Flow simulation as a service

Flow simulation as a service

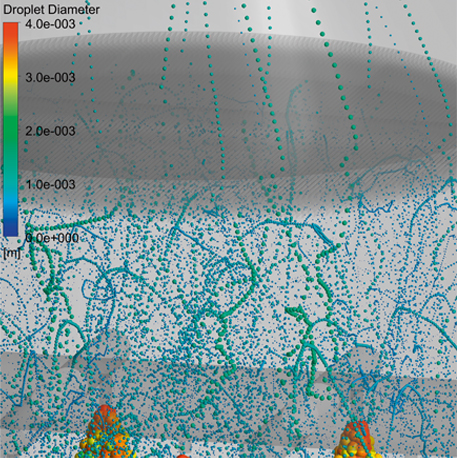

In spray drying, everything depends on having the right droplet size in the right place at the right time. Lechler’s latest CFD-based simulation methods utilises high-performance clusters with a computing power of around 8,500 GFlops.

Not only does this support the development of customized nozzles, but also the optimization of existing spray drying processes. We simulate nozzle applications and processes individually for your process environment and requirements.

Lechler's one stop shop – Your benefits

With Lechler as your partner, you are best prepared for all eventualities. We support you from the planning and build phase of new plants, to the operation and modernisation of existing spray drying facilities. Lechler is your one stop shop for all nozzle applications in a spray drying system. That means:

- one single point of contact for all atomization tasks

- time and cost savings thanks to greater system and process efficiency

- a simple, transparent and fast procurement process

- supplier consolidation

- the integration into our large partner network

Lechler nozzles for a wide range of applications in spray drying systems