Thus, for the first time with the IDTA from Lechler, double flat fan nozzles have been also approved into this new drift reduction class. Over the entire pressure range from 1 to 8 bar, the nozzles cover a total of three drift reduction classes. A flexible adaptation of the required buffer zone of certain plant protection products is therefore easy to implement at any time. The following ratings have been approved:

**** corresponds to 90% drift reduction,

*** corresponds to 75% drift reduction,

** corresponds to 50% drift reduction

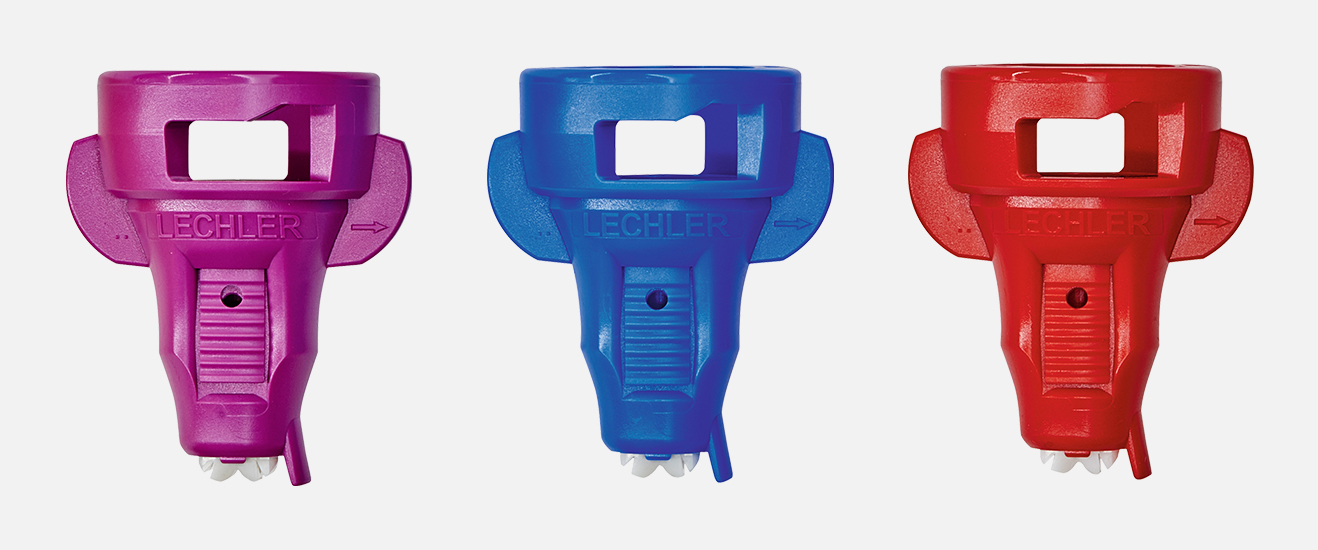

IDTA – an asymmetric air induction twin flat fan nozzle – sets a new benchmark in the double flat fan technology. Application technology as well as user safety have been improved. Several awards in different countries highligts this.

Spray direction 30° to the front and 50° to the back has shown best results in numerous tests in regard to high deposits at vertical targets and evenly distribution on front and back. Especially when increasing travel speed in the field.

Altogether, with the spray angle of 120° to the front and 90° to the back same effective spray width at the target area is achieved. No other asymmetric double flat fan shows this in the market. So overspray at field borders is technically impossible. In addition, with border nozzles sharp demarcation along field borders is possible.

Spray volume to the front is 60%, to the back 40% of total. Thus, gives an optimal cross distribution even where distance to the target may vary because of slopes or movement of the boom.

Droplet size at front jet is slightly smaller than back jet. Number of droplets in the spray is increased and so coverage is optimized. By this well balanced droplet spectrum the total coverage at vertical targets can be doubled compared to standard air induction flat fans.

User safety has been in focus too. The new design of nozzle and cap in one piece is well hand held and eases assembly on the boom. The new patented injector design enables manual removal without any tool – even the user is wearing his protection gloves. So the user is best protected when cleaning the nozzles.

Overview