VarioJet Nozzle Lances

Twin-fluid nozzles with a large orifice angle for uniform distribution of the liquid

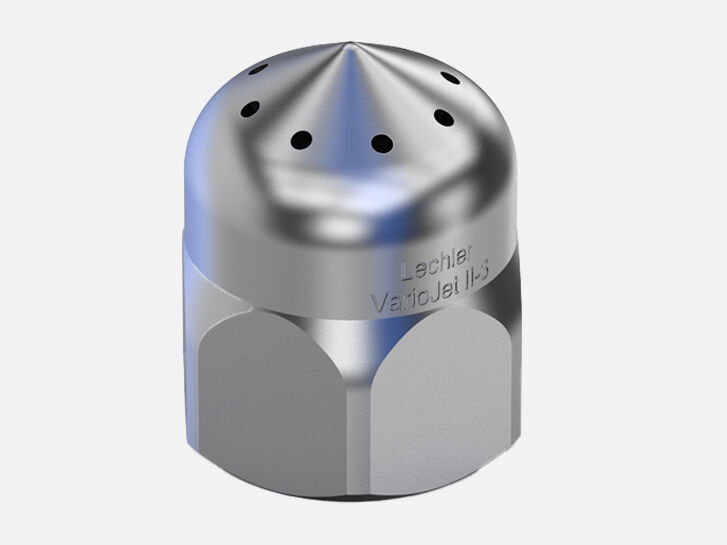

Lechler VarioJet nozzles are based on the principle of internal mixing, which ensures particularly efficient atomization. In this twin-fluid nozzle, the water is fed in axially. The liquid is then split into a thin liquid film by a cone. In the mixing chamber, this liquid film is split into very fine droplets by the atomizing air. The resulting two-phase mixture is atomized a second time when exiting via several circularly arranged holes, thus achieving a particularly fine and uniform distribution of the liquid.

Properties

The special design of the nozzle produces a spray jet with a large outlet angle, which has a uniform liquid distribution and a fine droplet spectrum with low specific air consumption.

The fineness of the droplet spectrum is significantly influenced by the air/liquid ratio and by the pressure level of the two flow rates. The following applies: the higher the air/ liquid ratio and the higher the pressure level of atomizing air and liquid is, the finer the droplet spectrum.

Use

- Gas cooling in gas cooling towers

- Gas cooling in gas-bearing pipes (ducts)

- Injection of ammonia water for DeNOx processes (SNCR/SCR)

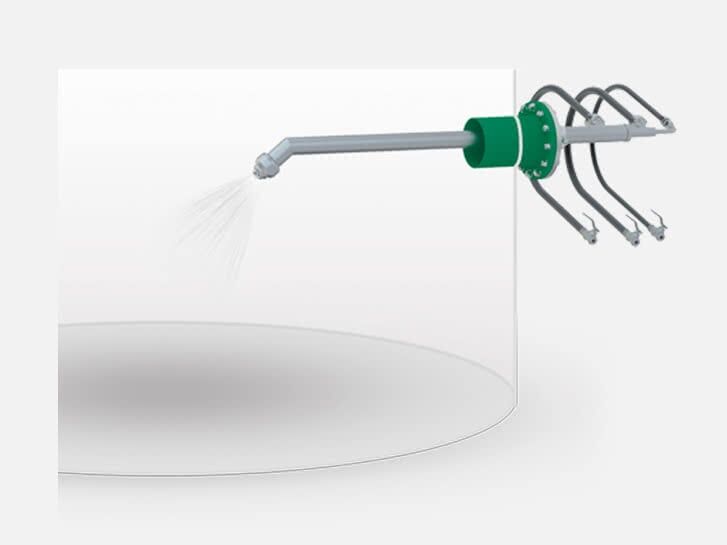

Functionality of VarioJet Nozzle Lances

The VarioJet nozzle lances are custom-designed to optimally place and align the spray jet in the flue gas duct. Individual requirements can be met to ensure optimum function.

The nozzle lances are made of high-quality stainless steel and are robustly built to ensure a long service life and high functional reliability. There are various material designs that can be selected according to needs and process-specific requirements.

The nozzles are designed to be easily maintained and can be quickly cleaned and replaced.

Various options are available for customizing the nozzle lances:

- Protection tube to increase the service life at higher temperatures, high dust loads and aggressive gases

- Expansion joint or stuffing box for expansion compensation at high temperatures

- Wedge flange, standard flange or special flange

- Shifting device to change the insertion lenght

- Pre-assembled accessory kits for process media connections

Further special customizations including wear protection, insulation, water cooling or coating are also available.