Axial-flow full cone nozzles

Lechler full cone nozzles have an extraordinarily uniform liquid distribution over the whole circular impact area. The high precision of distribution is achieved by orienting the liquid inlet to the centre of the swirl chamber of the nozzle.

The optimized x-style swirl insert ensures a high operating safety due to its large free cross-sections.

Series

Series 490/491

Non-clogging nozzle design. Stable spray angle. Particularly even liquid distribution.

Applications: Cleaning and washing processes, surface spraying, Container cleaning, foam precipitation, degassing of liquids.

Series 460/461

Very uniform spray pattern. Large free cross-sections, due to optimized x-style swirl insert.

Applications: Cleaning and washing process, cooling of gaseous fluids and solids, surface spraying, spraying onto mats in air washers, improving of chemical reactions.

Series 405

Very uniform spray pattern.

Applications: Surface spraying, spraying over packings, cleaning and washing process, chemical process engineering, cooling of gaseous fluids and solids, water treatment.

Series 403

Very uniform spray pattern.

Applications: Surface spraying, spraying over packings, chemical process engineering, cooling of gaseous fluids and solids.

Series 419 "FreeFlow"

Non clogging due to very large free cross sections. Very stable spray angle. Uniform liquid distribution.

Applications: Cleaning and washing processes, dust control, absorption, distillation

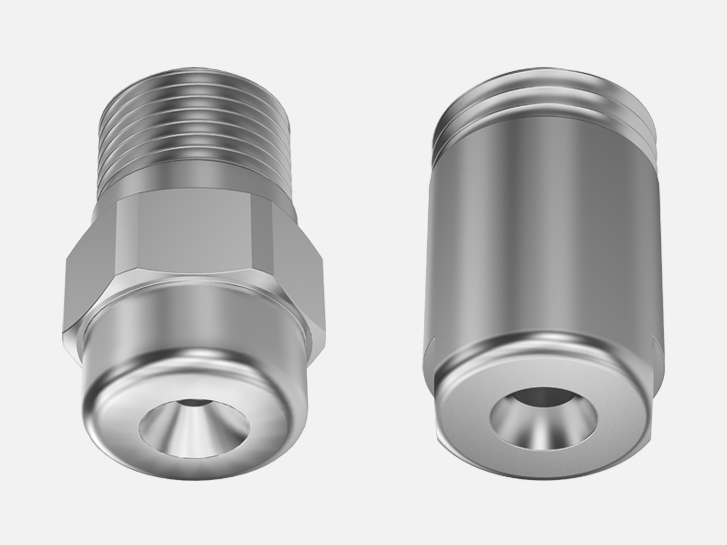

Series 4H7

Compact, housingless design for screw-in. Low weight. High resistance to clogging due to large free cross-sections combined with optimized liquid distribution.

Applications: wet desulphurisation/ scrubber, gas cooling (quenching) as well as for absorber applications.

Series 4Fx

Spiral full cone nozzle with robust and maintenance-free design. Fine droplets.

Applications: General Industry, flue gas desulphurization, cooling and gas humidification in general.