Twin-fluid nozzles for secondary cooling in continuous casting processes

Twin-fluid nozzles for every continuous casting process.

Nozzle overview

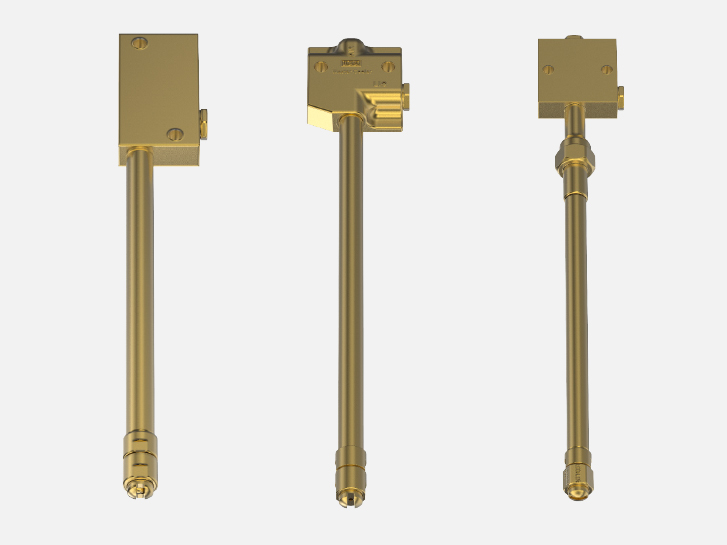

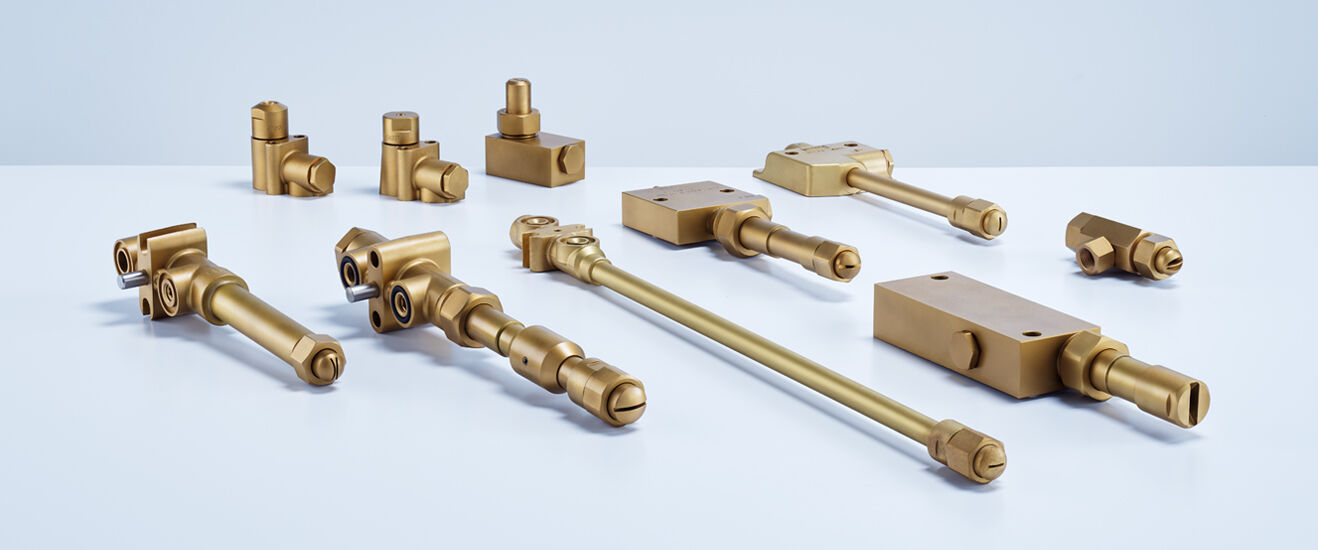

Billetcooler FLEX

- Stable spray angle (60°) within turndown ratio

- Water flow rate: 0.3 to 8 l/min

- Foot print: round

- Flexible spray water distribution

Billetcooler oval spray

- Mounting on horizontal spray rings and also on vertical nozzle headers

- Spray angle: 60/90° (wide), 30/45° (deep)

- Flow rate range from 0.4 l/min to 12.4 l/min

- Foot print: oval

Billetcooler cone spray

- Mounting on horizontal spray rings and also on vertical nozzle headers

- Spray angle: 45°, 60°, 90°

- Flow rate range from 0.4 l/min to 8.0 l/min

Slabcooler ECO

- Reduced compressed air consuption results in reduced energy consumption, reduced operation costs and reduced CO2 emission

- Excellent cost/performance ratio (ROI << 1 year)

- Plug and spray: No modification of segment piping required, conversion during regular segment maintenance, change back to status quo possible

- Well proven concept – high operation safety

MasterCooler SMART

- Vertical piping with square pipes

- Mounted onto vertical adapter plates

- Spray angle: 50°, 80°, 90°, 110°, 120°

- Volume rate at 7 bar: 5.70 l/min to 51.1 l/min

Mastercooler HARD HARD COOLING

- Mounting on horizontal spray rings and also on vertical nozzle headers

- Spray angle: 45°, 60°, 90°

- Flow rate range from 0.4 l/min to 8.0 l/min