Spray headers for pickling and processing lines

Washing, pickling acid spraying, rinsing, cooling, strip edge drying. Those are the most common spray applications in processing lines for strips and wire. Headers made from stainless steel or from various plastic materials for all types of processing lines, Lechler can do it all.

Overview Spray Headers for Pickling and Processing Lines

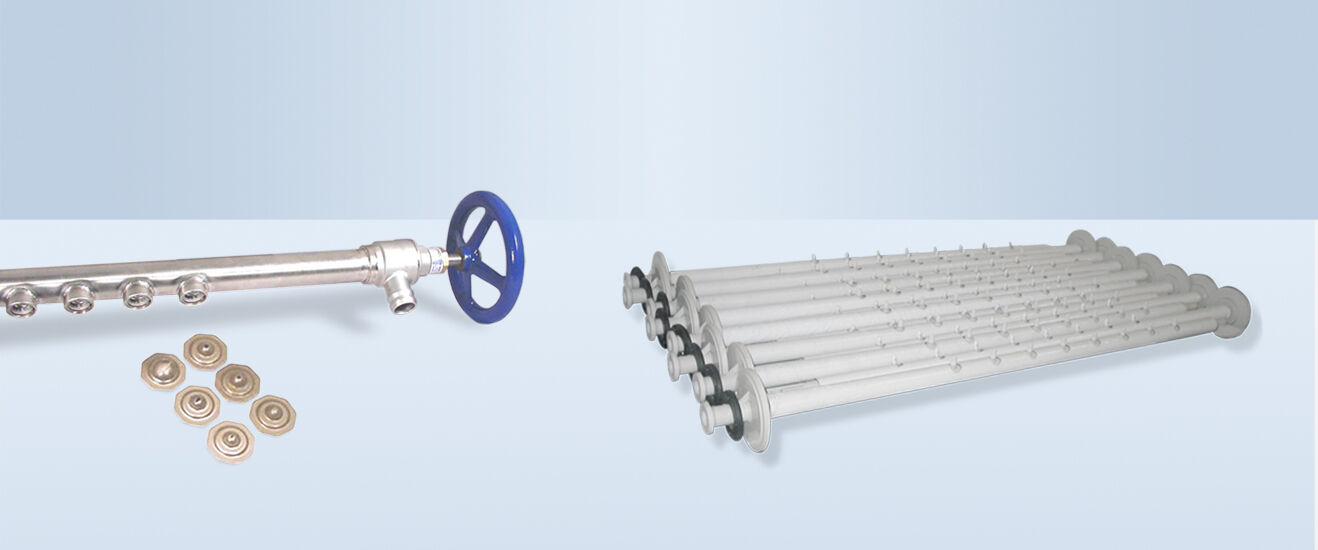

Plastic headers

Typical rinsing headers of a steel strip pickling line made from PP and Lechler nozzles made from PVDF.

Self cleaning Lechler STAMM showers

Clog-free operation by means of an inline cleaning brush assembly. With the simple turn of a manual or automatic handle, internal brushes clear debris from our self-aligning nozzles.

Typical applications are rinsing, low or high pressure spray cleaning of strips and brushes in pickling and galvanizing lines.

Lechler air mist headers for CAP-lines

It is in the cold continuous annealing and pickling line where the treatment of the strip is performed, providing the metallurgical structure of the stainless steel.

At temperatures between 800 °C and 200 °C the recrystallization takes place in the furnace before the strip is cooled from top and bottom by means of air blowing, conventional water spray cooling and air mist spray cooling. Often it is a combination of all three methods. Varying steel grades and line speeds require specific cooling rates to avoid carbide precipitation at grain boundaries. The special Lechler air mist cooling header design is providing exactly that. The 1 : 10 water control ratio (turn-down ratio) allows a precise setting with perfect spray patterns from min. to max. line speeds. The large spray overlaps ensure a uniform cooling over the entire strip width for an optimal thermal homogeneity across the strip.