Scrubber/gas cooling in the shipbuilding industry

Nozzles and nozzle systems for gas cooling/gas treatment are used in the following applications in the shipbuilding industry:

- Scrubbers (further information)

- Urea injection

- Gas tank

- Exhaust gas pipe

Corresponding products

Axial-flow full cone nozzles for scrubbers

Series 405

Very uniform spray pattern.

Applications: Cleaning and washing processes in exhaust gas cleaning systems (SOx reduction), cooling of gaseous and solid substances.

Axial-flow full cone nozzles for scrubbers

Series 403

Very uniform spray pattern.

Applications: Cooling of gaseous and solid substances, spraying over packings, cleaning and washing processes in exhaust gas cleaning systems (SOx reduction).

Axial-flow full cone nozzles for scrubbers

Series 419 "Free Flow"

Particularly insensitive to clogging thanks to very large free cross sections. Stable spray angle. Uniform spray pattern.

Applications: Gas washing, spraying over packings, dust control,absorption, distillation.

Axial-flow full cone nozzles for scrubbers

Series 421

Even full cone distribution, high flow rates.

Applications: Surface irrigation, cooling and cleaning of gases, water recooling, column irrigation and improvement of chemical reactions via surface enlargement.

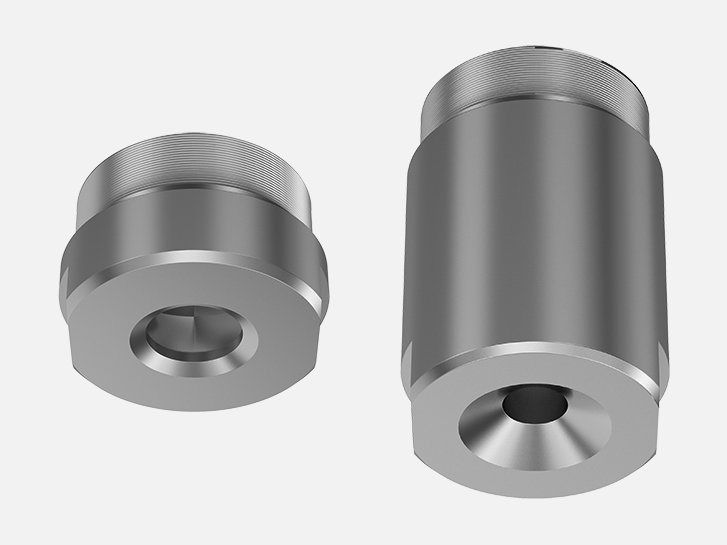

Axial-flow full cone nozzles

Series 490/491

Non-clogging nozzle design with a very stable spray angle, particularly even liquid distribution and large free cross sections.

Applications: Cleaning and washing processes, surface spraying, container cleaning, foam precipitation, degassing of liquids.

Tangential full cone nozzles

Series 422/423

Tangential design has no internal swirl device for maximum clog resistance. Stable spray angle. Uniform spray.

Applications: Cleaning and washing processes such as windscreen washing, NBC protection, droplet separator washing, foam precipitation, cooling of gaseous and solid substances.

Twin-fluid nozzles for exhaust gas cooling

Series 170/180

Efficient atomization by mixing liquid medium and gas. Internal mixing principle (a mixing chamber inside the nozzle combines a gas and a liquid to produce an intensive two-phase mixture). Extremely fine atomization with good control behavior. Large clear cross sections. Lower air consumption than for nozzles with external mixing. Maintenance-free operation.

Applications: Gas cooling, humidification, flue-gas desulfurization, absorption. The large free cross sections of the nozzle permit maintenance-

free operation even for atomization of viscous and abrasive media with high solids load.

Twin-fluid atomizing nozzles for gas treatment

Series 76X

Twin-fluid nozzle with external mixing for production of fine droplets. Modular concept. Wide range of combination options.

Applications: Gas treatment, combustion processes.

Solid stream nozzles for high-viscosity suspensions and fluids. Nozzles with pre-atomization for high atomization efficiency.

Axial-flow hollow cone nozzles for gas cooling

Series 214/216

Fine, uniform hollow cone spray.

Applications: Cooling and cleaning of air and gas, dust control, spraying onto filters, spray drying, desuperheating.

Cluster nozzles for gas cooling

Series 502/503

Fine full cone atomization with the aid of several hollow cones spraying into one another.

Applications: Cooling of gaseous and solid material, desuperheating, chlorine precipitation, absorption as well as for improvement of chemical reaction by enlarging the contact area.

Further applications in the shipbuilding industry

Fire protection

For hatch covers, lifeboats, ship walls, ammunition rooms and helicopter decks.

Fire protection in the shipbuilding industryNBC measures (Atomic / Biological / Chemical)

For object protection and surface cleaning.

NBC measures in the shipbuilding industryCleaning

For windows, anchor chains, gray/black water tanks, droplet separators and scrubbers (internal cleaning).

Cleaning in the shipbuilding industry