Lechler IDTA nozzle:Asymmetric nozzles redefined

How to achieve optimum application in cereals, potatoes and vegetables?

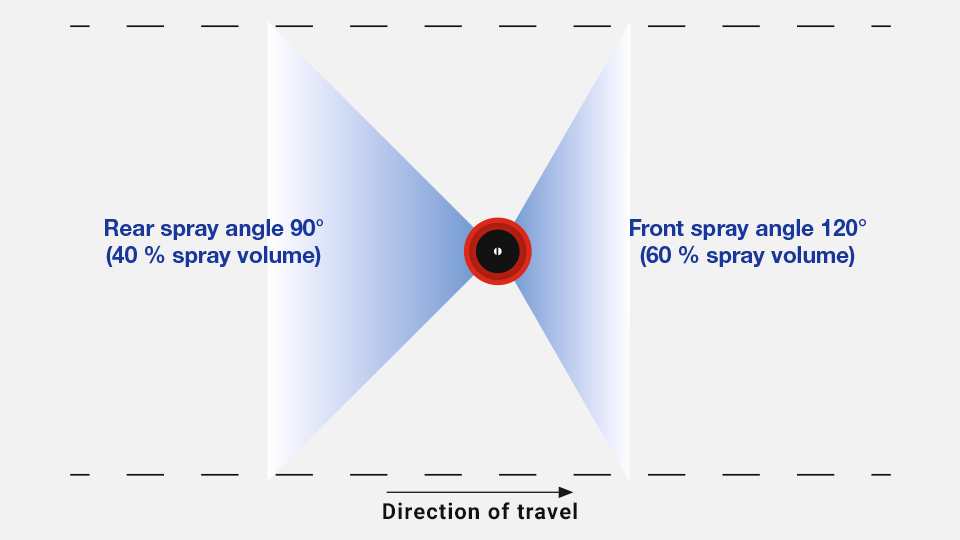

With the introduction of the new, asymmetric IDTA nozzle series, Lechler has recently set a new standard for "long" twin flat spray nozzles. The innovative design with two spray angles of 120° respectively 90° in one nozzle and adapted distribution of the liquid quantities of 60% to 40% is unique and has meanwhile convinced many professionals in the use of this innovative nozzle. In addition, there is the high drift reduction of up to 90% and 95%.

The use of modern crop protection sprayers with GPS section control, optimized boom guidance and suspended chassis enables higher speeds in order to increase capacity and use spray windows effectively. At the same time, the application quality and also the drift reduction must be secured with the optimum nozzle technology.

In potatos or vegetables, higher water rates are applied depending on the growth stage of the crop, compared to normal arable farming. A "clean" finish at the border of the field without "overspraying" the field boundary is very important in order not to damage neighboring crops.

The innovative design of the first real asymmetric series IDTA meets these requirements perfectly. Quite deliberately, the nozzle works with a 30 degree spray angle in the direction of travel against the air resistance/wind, and together with the proportion of 60% of the volume achieves very good coverage at the front of the crop. The spray fan with 50 degrees angled to the rear effectively improves the application on the back of the crop especially at speeds beyond 10 km/h. However, this relatively flat angle to the rear requires adjustments in the design of the nozzle, as the spray fan with "normal" spray angle of 110/120° would become very wide and thus sensitive to drift and significant overspray of the field boundary.

This is where the IDTA comes in with the innovation of 120 degrees to the front and "only" 90 degrees spray angle to the back. The rear spray fan also works just as wide as the front fan and is less sensitive to drift due to the reduced angle with a coarser spray. In combination with a "long" border nozzle of the IS series in the same color, absolutely "sharp-edged" application is also possible.

Due to the long injector design and a wide pressure range of 3 – 7 bar in practice, higher water volumes can also be applied in potato and vegetable cultivation in a drift-reducing manner at varying speeds – for example 350 l/ha at 9 km/h with the IDTA 120-05 or 600 l/ha with the IDTA 120-08. Essential coverage with contact and semi-systemic products, evenly on the front and back of the plants, is optimal, allowing the full potential of the active ingredients to be utilized. Copper, sulfur or other contact products are also increasingly used in conventional vegetable farming as options for not exceeding maximum quantities of PPP's in the crop. Twin fan nozzles and sufficiently high water volumes ensure good deposition when applying in dense crops with a large surface of leafs.

For the final ear treatment in wheat, IDTA 120-04 would be a good choice at 200 l/ha and 12 km/h.

See here the approvals for up to 90/95% drift reduction for your country.