Low-pressure nozzles

The product range of the low-pressure nozzles includes the series 610, 612, 616/617, 632/633, 652, 652.xxx.8H.03, 612.xx.5E.03, 656/657, 660, 664/665, 646, 688/689, 686 and 684.

Series

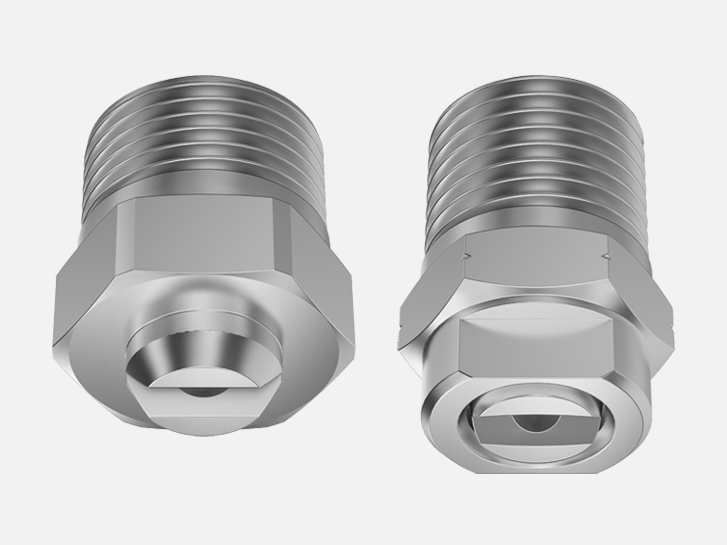

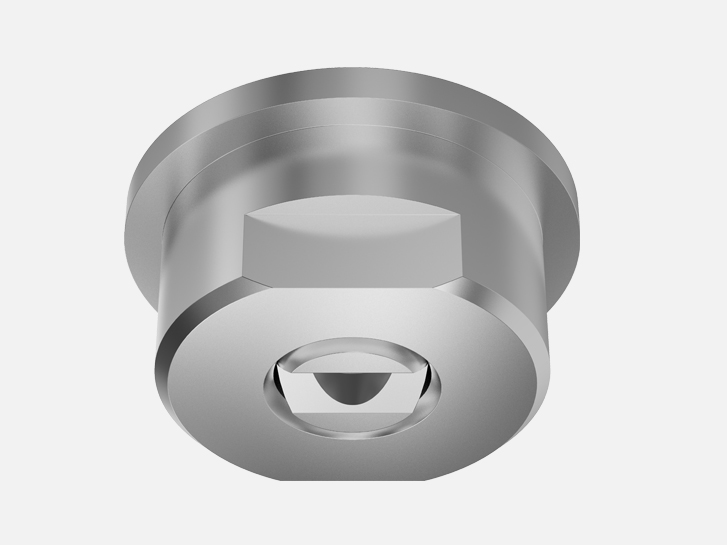

Series 632/633

Standard design with conical, self-sealing thread connection. Stable spray angle. Uniform, parabolical distribution of liquid. Spray pipes equiped with these nozzles show an extremely uniform total distribution of liquid.

Applications: Spray cleaning, surface treatment, filter cleaning, belt cleaning, lubricating, coating.

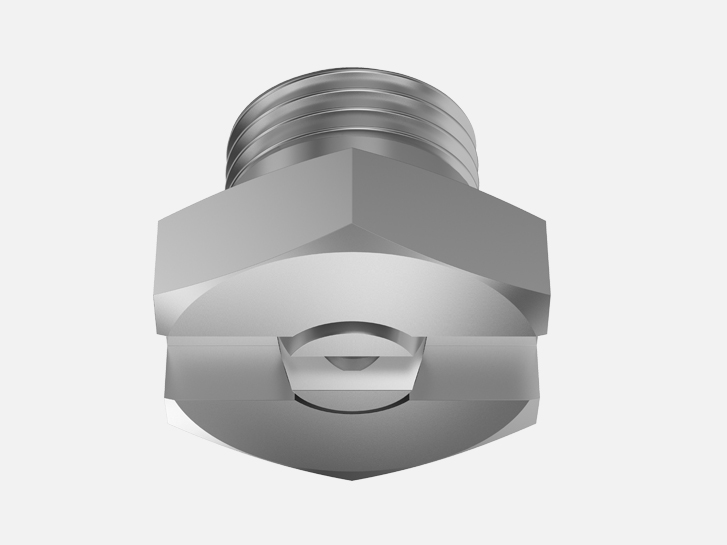

Series 610

Compact design, suitable for narrow installation conditions. Stable spray angle. Uniform, parabolic distribution of liquid.

Applications: Cleaning installations, cooling headers, spray pipes.

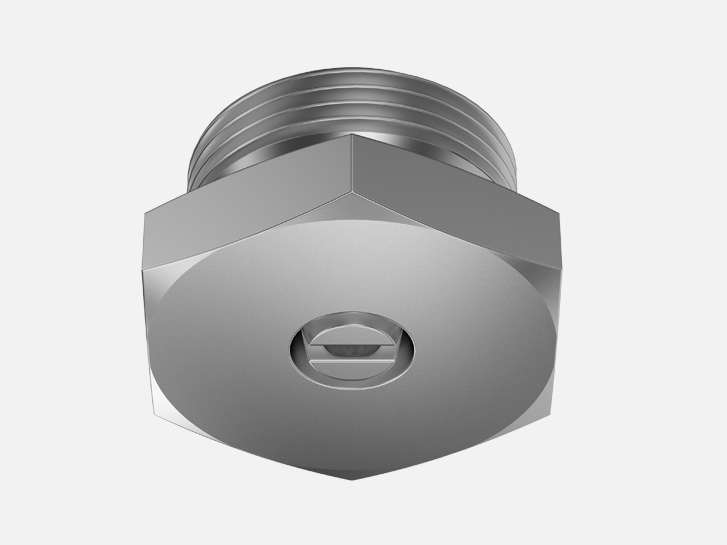

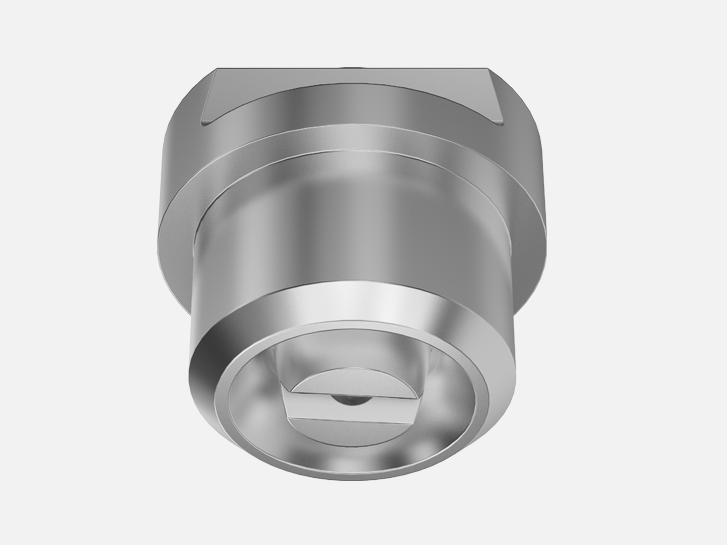

Series 612

Short design with flat gasket, well applicable e. g. for square tubes. Uniform, parabolic distribution of liquid. Composite spraying nozzles have an extremely uniform total liquid distribution.

Applications: Cleaning installations, cooling headers spray pipes.

Series 616/617

Uniform, parabolic distribution of liquid. Increased non-clogging features. More jet power, less fog.

Applications: Cleaning installations, rain curtains, gravel washing, spray pipes, foam spraying, roll cooling, cooling of rolled stock.

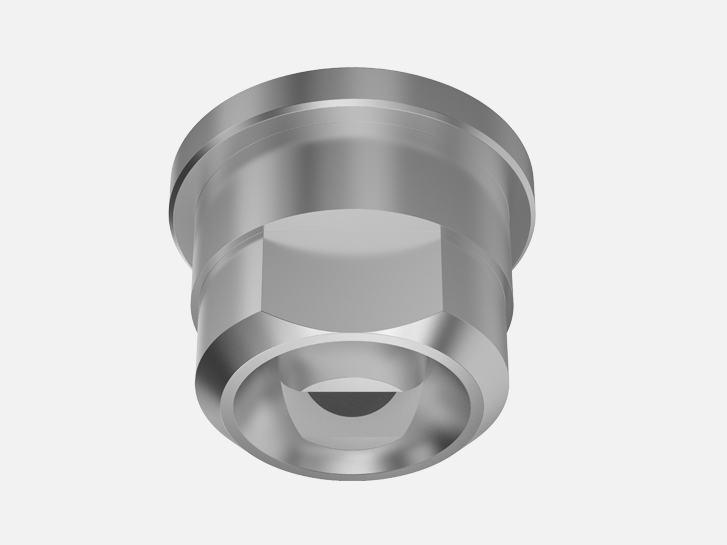

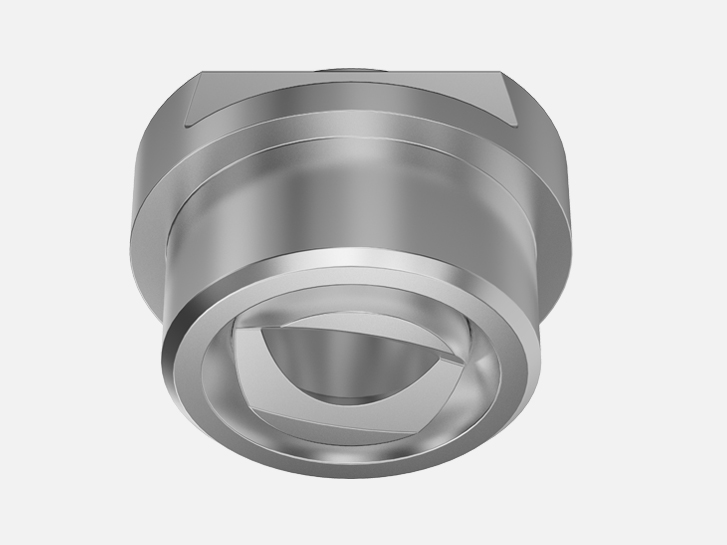

Series 652

Assembly with retaining nut. Easy nozzle changing, simple jet alignment. Uniform, parabolic distribution of liquid. Spray pipes equiped with these nozzles show an extremely uniform total liquid distribution.

Application: Spray cleaning, surface treatment, filter cleaning, belt cleaning, lubricating, coating.

Series 652.xxx.8H.03

Especially low flow rates. Parabolic liquid distribution.

Applications: Belt lubrication, moistening, spraying of food products, moisturization of rollers, oiling, lubrication of metal sheets.

Series 612.xxx.5E.03

For pressing into pipes. Stable spray pattern. Uniform, parabolic distribution of liquid.

Applications: Cleaning and rinsing, dish washing.

Series 656/657

Assembly with retaining nut. Easy nozzle changing, simple jet alignment. Uniform, parabolic distribution of liquid. Increased non-clogging features. More jet power, less fog.

Applications: Cleaning installations, gravel washing, cooling headers, spray pipes, roll cooling, cooling of rolled stock.

Series 660

Assembly with retaining nut. Automatic jet alignment due to dove-tail guide. Stable spray angle. Uniform, parabolic distribution of liquid. Spray pipes with these nozzles show an extremely uniform total liquid distribution.

Applications: Cleaning installations, cooling headers, spray pipes.

Series 664/665

Assembly with retaining nut. Automatic jet alignment due to dove-tail guide. Stable spray angle. Uniform, parabolic distribution of liquid. Spray pipes with these nozzles show an extremely uniform total liquid distribution.

Applications: Cleaning installations, cooling headers, spray pipes, roll cooling, cooling of rolled stock.

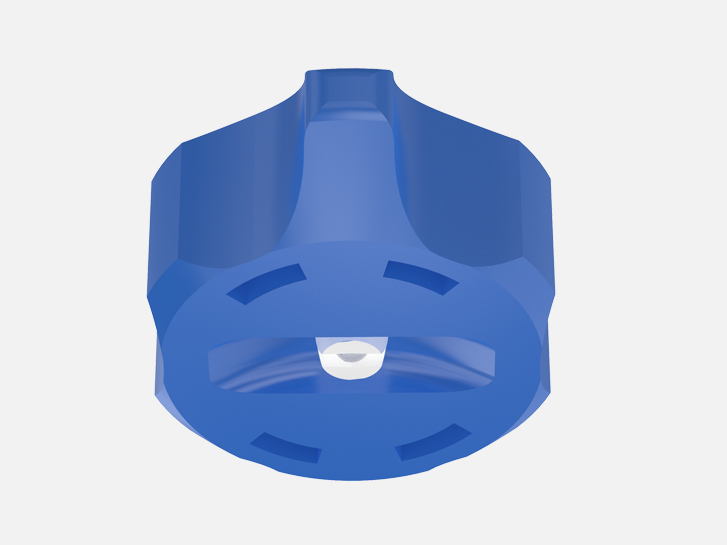

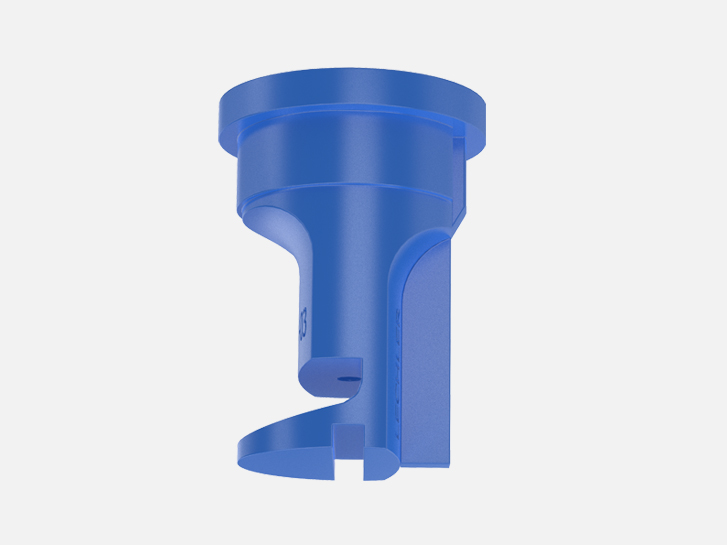

Series 646

Quick and easy assembly with bayonet quick release cap. Adjusted spray directions. Uniform liquid distribution.

Applications: Bet cleaning, surface treatment, cleaning, coating processes.

Series 688/689

Hard, sharp flat fan, narrowly delimited jet pattern. Not prone to clogging.

Applications: Cleaning, washing, degreasing and phosphating, preparation techniques.

Series 686

Wide flat fan with a sharply delimited jet pattern. Particularly clog-proof.

Applications: Foam control in storage tanks, crate washers, cleaning and washing processes requiring powerful and concentrated water jets.

Series 684

Assembly with retaining nut. Wide flat fan with a sharply delimited spray pattern. Particularly colg-proof. Easy nozzle changing, simple jet alignment.

Applications: Foam control in storage tanks and sewage treatment plants. Cleaning and washing process, requiring powerful and concentrated water jets.