Pickling

High quality nozzles for your high quality process

The closer it comes to the final step of a production process the more important the direct result is. Hence, the pickling line has a decisive function in the entire production chain of steel.

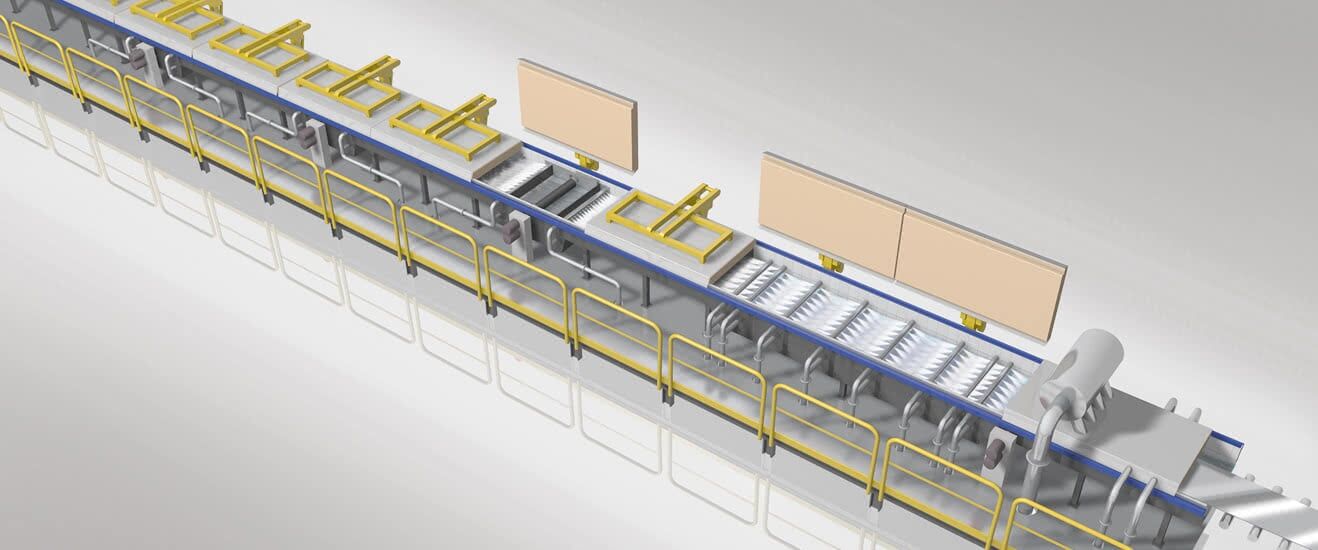

Example of a staggered nozzle arrangement

Example of a staggered nozzle arrangementBlow-off

After leaving the rinsing section the water should be removed from the strip. Typically, nozzles for compressed air could manage this job. Especially, at the edges of the strip remaining rinsing water droplets have to be blown off. The multi-channel Whisperblast nozzles are especially designed to offer highest performance. Installed properly they are most effective. The air nozzles must cover the full range of the possible strip edges. Therefore, minimum and maximum strip width as well as the accuracy of the horizontal strip guidance has to be taken into account.

Strip edge blow-off with multi-channel nozzles for compressed air

Strip edge blow-off with multi-channel nozzles for compressed airSpray headers

Precise nozzle sprays need to be installed accurately on precise spray headers. Complete spray headers could be manufactured by Lechler according to your drawings. Lechler could produce headers in material stainless steel as well as in plastics according to your specifications.

Spray headers equipped with tongue type nozzles

Spray headers equipped with tongue type nozzlesMaintenance

As the nozzles and accessories are exposed to the rough operation conditions their state should be checked regularly. Especially the nozzles themselves are subject to wear, clogging or damage. A worn out nozzle could not fulfill the high functional demand anymore. An uneven overall liquid distribution and hence a non-uniform product surface could be the result. Worn out or clogged nozzles must be replaced by new ones in regular intervals to ensure optimum operation.

Influence of clogged nozzles to the liquid distribution

Influence of clogged nozzles to the liquid distributionProduct overview

Precision Spray Nozzles for Pickling Lines

Nozzles for pickling lines require the highest quality to optimally support the processes in the production of your high-quality products.