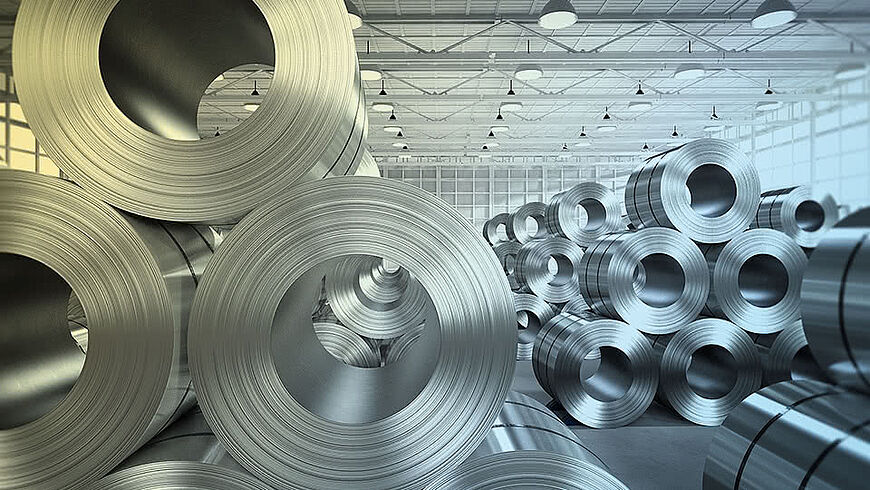

Aluminium industry

Lightweight and with a perfect surface.

Uniform aluminum rolling thicknesses require highly accurate cold rolling mills. Local, process-related heating of the rollers impair their geometry and the rolling quality. In order to prevent this, Lechler has developed SELECTOSPRAY a comprehensive system for selective roll cooling. For highly efficient pickling lines, we offer a broad portfolio of nozzles for atomizing aggressive media. Again, your optimal solution is just a phone call away. In addition to tried-and-tested systems, we provide our customers with support in the form of individually tailored solutions.

Professional reports

Walzenkühlung: General aspects of roll cooling for hot & cold rolling millsFachbericht aus SEAISI Quarterly Journal (SQJ) 2014, 43, 2; 49-56 – Hubertus WenigRead now (pdf, 1 MB)

Walzenkühlung: Fundamentals of roll cooling and control of flatness at primary cold reductionContribution paper – Daron LloydRead now (pdf, 827 KB)

Walzenkühlung: Flatness and profile the problems that can exist in the design of the spray actuatorsContribution paper für The Institute of Materials, Minerals and Mining, Achieving Profile & Flatness in Falt Products, Austin Court, Birmingham (UK), 2006 – David TuckerRead now (pdf, 904 KB)

Walzenkühlung: Parameters for effictive roll coolingConribution paper für Saruc Southern African Roll Users Conference, Emuleni Conference Centre Vanderbijlpark, South Africa – Jürgen FrickRead now (pdf, 977 KB)

Contact

Lechler Spray Technology Sdn. Bhd., MalaysiaMetallurgy DivisionPhone +603 6142 1288 (General Line)Fax +603 6156 1153info(at)lechler.com.my