Descaling

Quality improvement and plant efficiency through effective descaling

Regarding hot rolling of steel, the quality of the rolled metal surfaces depends to a large extent on effective descaling. In order to avoid surface damage, iron oxide scale layers are therefore removed from the hot steel surface by high-pressure water spraying prior to the actual hot rolling process. The selection of the best descaling nozzles and their optimum arrangement in the process is therefore a key factor. At the same time, this enables potential energy savings to be realized, which counteract rising energy costs or result from ecological considerations.

During descaling, the spray impact of the nozzle is of particular importance. The high impact of descaling nozzles is achieved by their specific design as flat fan nozzles with a particularly low spray depth, for which special nozzle tips are used in combination with stabilizers. Lechler descaling nozzles are well-known under the brand name SCALEMASTER and offer the optimum conditions for high product quality, low maintenance costs and low roll wear.

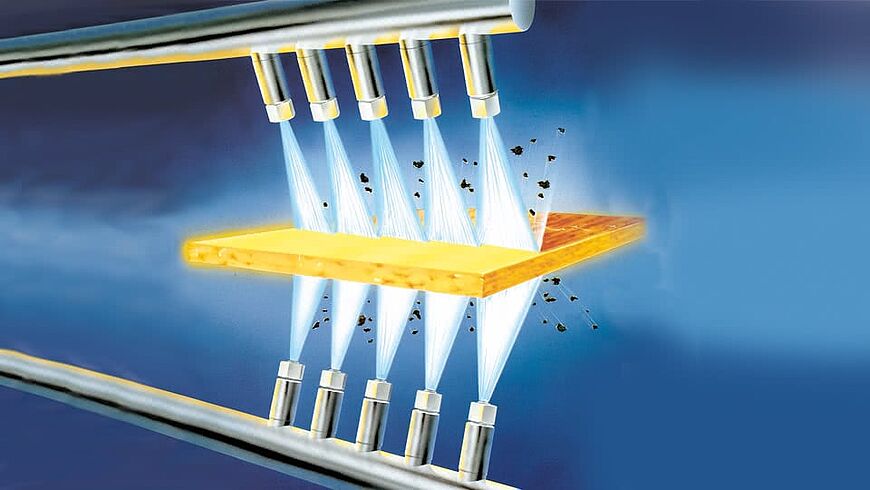

Hydro-mechanical descaling process

In hydro-mechanical descaling processes the jets are formed by special descaling nozzles which are arranged on spray headers in a so called descaling box (or mill descalers) through which the product (slab, strip, billet, bloom, beam blanket, etc.) travels. Working pressure range from 80 to 450 bar.

Because the interface bond between the scale and the steel surface can be very different a proper descaling nozzle setup is of major importance to reach best descaling results. The setup of a descaling system includes nozzle parameters and the nozzle arrangement. Both have a major influence on the descaling factors, hence the descaling performances. The impact with which the descaling water impinges on the surface is the main criteria to measure the efficiency of a descaling nozzle, this is given in N/mm2.

Lechler SCALEMASTER Descaling Nozzles

The most exacting demands placed on the surface quality of rolled steel material combined with a further reduction in the amount of energy used can only be met by using state-of-the-art descaling nozzles.

- MicroSCALEMASTER with smallest dimensions for space saving mounting

- SCALEMASTER ECO+ with a remarkable increase of impact for better descaling

- Water Stop Valve for Scalemaster nozzles to stop the water flow at low pressure

Product overview

Lechler SCALEMASTER Descaling Nozzles

Lechler SCALEMASTER descaling nozzles ensure the best surface qualities and low energy consumption.

Professional reports