Lechler Carbide Recycling (CaRe)

Matter matters

Efficient processes with nozzle technology rely on spray nozzles with a long service life. For this reason, components that are subjected to higher loads must be made of materials that are characterized by hardness and are correspondingly wear-resistant. In the food industry, these components also have to be hygienic and easy to clean. The perfect material for such applications is tungsten carbide. Various series from Lechler are made of a unique tungsten carbide that, compared to other materials available on the market, boasts a superior wear rate and better withstands chemical attack due to its unique binder technology.

Lechler Carbide Recycling (CaRe) in detail

To date, finally spent tungsten carbide wear parts are simply discarded. But now there is a sustainable alternative that reverses the manufacturing process back to the raw material ready for reuse.

The Lechler Carbide Recycling program offers just that – the ability to return your spent tungsten carbide nozzle spares for recycling. This way, you not only reduce your carbon footprint, but also benefit financially. For the quantity returned, you will receive a credit to your account.

Lechler’s CaRe program aims to conserve limited primary resources, while reducing the consequences of intensive mining such as the pollution of air, water and soil.

Potential energy savings and reduction of the total CO2 balance

When tungsten is recovered by recycling from secondary raw materials, significant energy and CO2 savings are possible.

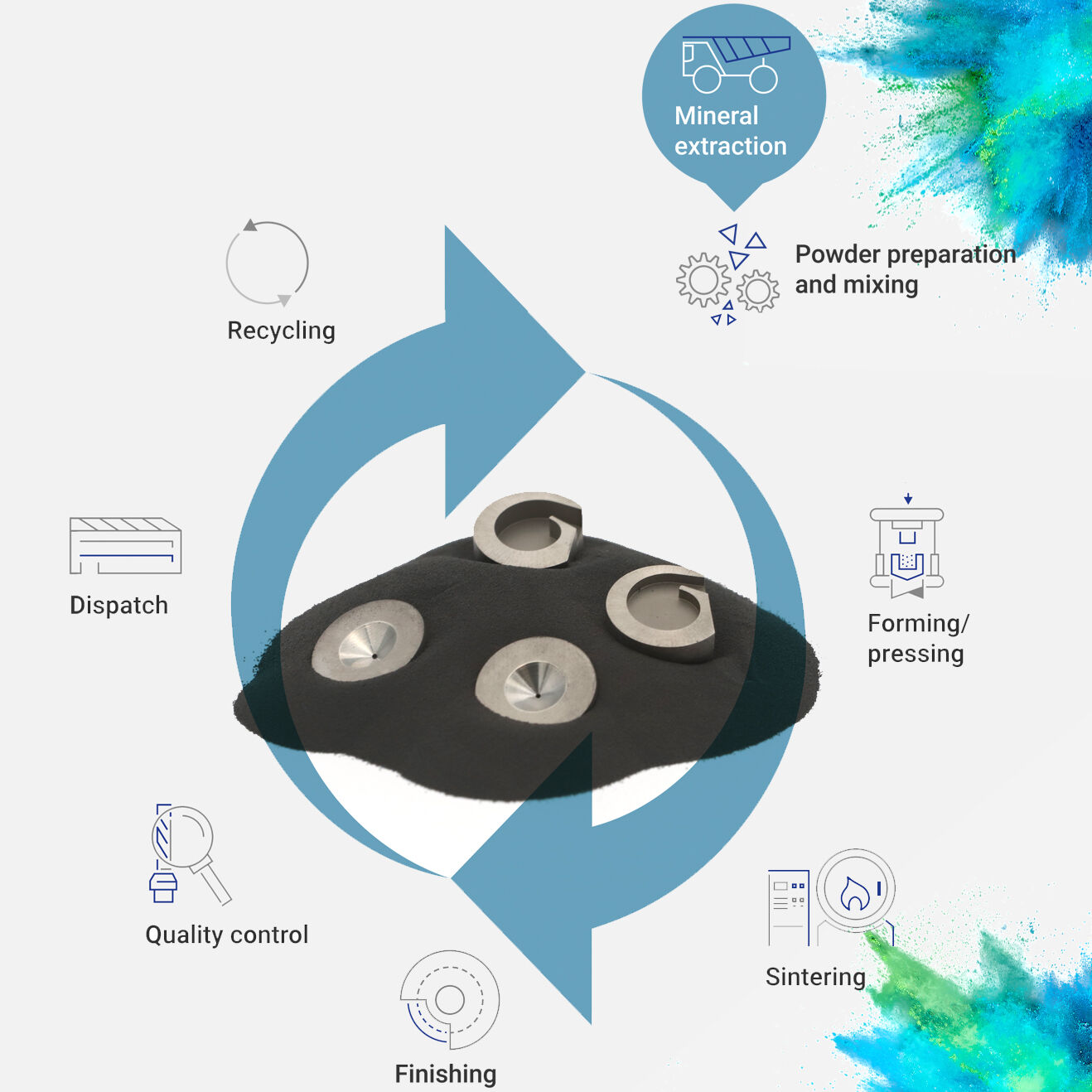

The carbide powder circle

Nozzles in the Lechler CaRe program

Do you CaRe?

Should you wish to learn more of Lechler’s CaRe program, or are interested in adopting the scheme, please don’t hesitate to contact your local Lechler representative. Carbide recycling program not available in all regions.