Many tanks have built-in equipment such as agitators or baffles which can create spray shadows. Whether a certain nozzle is able to reliably clean all surfaces of the tank under these conditions cannot be decided with certainty on the basis of just a visual inspection.

With our new and unique TankClean software, we can help you to find the optimum solution for perfectly cleaning your tank. To do this, we replicate the tank geometry in the software and then simulate the spraying operation. Operation of all Lechler tank cleaning nozzles can be simulated – from the static spray ball to the high-impact tank cleaning machine. The result of the simulation is documented and provided in a PDF or video file. Simulation with TankClean can already be used as the basis for optimum cleaning in the planning phase of new tanks, but is also suitable for optimizing existing tank cleaning processes.

Our unique service – your individual benefit

Planning certainty |

Process optimization |

Process reliability |

Cost and time savings |

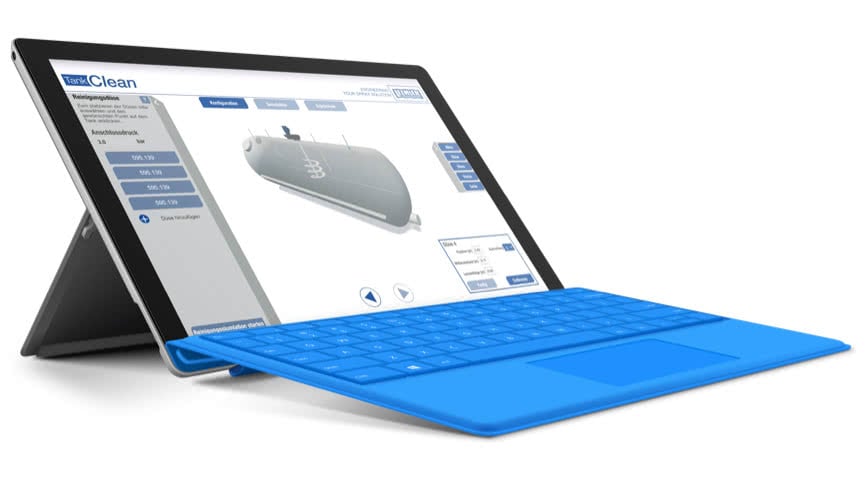

TankClean user interface – clearly arranged and intuitive

- Individual adaptation of tank geometries and built-in equipment

- Selection of the right tank cleaning nozzles

- Realistic simulation of the cleaning process

- Documentation of the simulation results, including additional planning aids