Energy Efficiency up, CO2 down

At METEC 2019, you can explore innovative solutions by Lechler that help you relieve your budget and the environment – by using energy more efficiently.

E3 = mc » Energy, Efficiency, Excellence = minimized costs

With the new analysis program MillConfig.Descale, you can display potential water savings, and the energy consumption during descaling, for the entire hot rolling mill. The respective reduction in CO2 emissions is also shown.

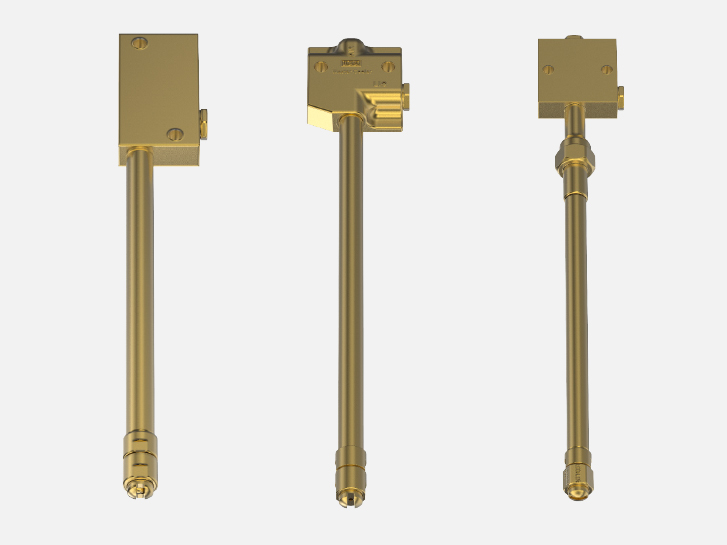

The new air-mist nozzle Slabcooler ECO by Lechler sets new efficiency standards as well, by reducing consumption of compressed air. It has been specially developed for secondary cooling in continuous slab casting.

Combined with the proven Lechler DESCALE configuration program, the new MillConfig.Descale analysis program displays the optimization and savings potentials of your entire rolling mill, in a clear and customized way. See for yourself – and benefit from the advantages of Lechler MillConfig.Descale.

- Decrease water and energy consumption

- Reduce CO2 emissions

- Cut costs

| This completely new nozzle was developed to reduce the consumption of expensive compressed air in the secondary cooling of continuous slab casting plants. Lechler’s innovative solution helps permanently lower energy consumption, therefore cutting costs and decreasing CO2 emissions. Also good to know: Thanks to the “plug & spray” design, conversion is quick, easy, and inexpensive – without costly modifications to piping. |