How to avoid quality problems and loss of profit by regular maintenance of nozzles

Nozzle maintenance should be a regular part of your production process if you want to keep your lines running efficiently. This is why the engineers at Lechler developed a Five Step Process for extending nozzle life. Learn about the factors that can cause poor nozzle performance and what signs to look for when your nozzle is not spraying properly. By following the Five Step Process, you can learn how to prevent significant quality problems and profit loss. Regular maintenance is also important for our high-quality tank cleaning nozzles. As these nozzles are more complex, Lechler has developed a maintenance concept especially designed for tank cleaning nozzles.

Factors causing poor nozzle performance

|

|

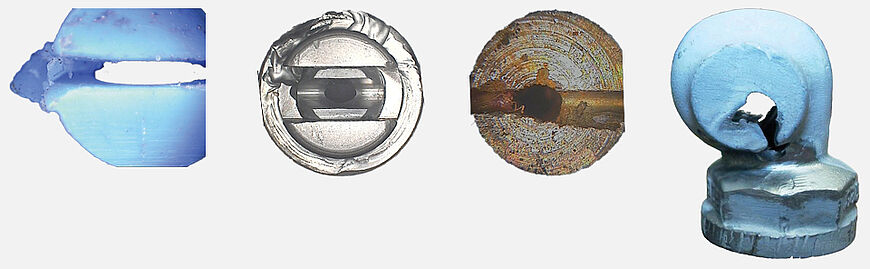

Examples of nozzles that show damage such as erosion, wear, corrosion or contamination.

Examples of nozzles that show damage such as erosion, wear, corrosion or contamination.Spray charactersitics – What to look for?

| Spray characteristic | Type of nozzle damage | Spray performance | |

| Flow rate | Orifice wear | Increase flow rate | |

| Spray angle | Orifice wear | Noticeable change in spray angle | |

| Liquid distribution | Orifice damage | Effective coverage or distribution will be compromised | |

| Spray impact | Worn nozzle | Lowered impact | |

| Droplet size | Orifice wear | Liquid flow increases, creating large droplets causing poor performance |

Extending nozzle life – Five Step Process

- Change nozzle material

Environment can affect the material of a nozzle, which can cause erosion and wear. Selecting the proper material is critical to ensure longer nozzle life. Nozzle materials such as PTFE or PVDF work better than metals if corrosive chemicals are being sprayed. - Add line strainer or filter

Proper filtration can eliminate unwanted particulates, which can result in clogging and restricting nozzle flow. For this reason, a line strainer, or built in nozzle strainer is recommended with a screen mesh size that will prevent particulates from entering the nozzle. - Use proper tools and cleaning care

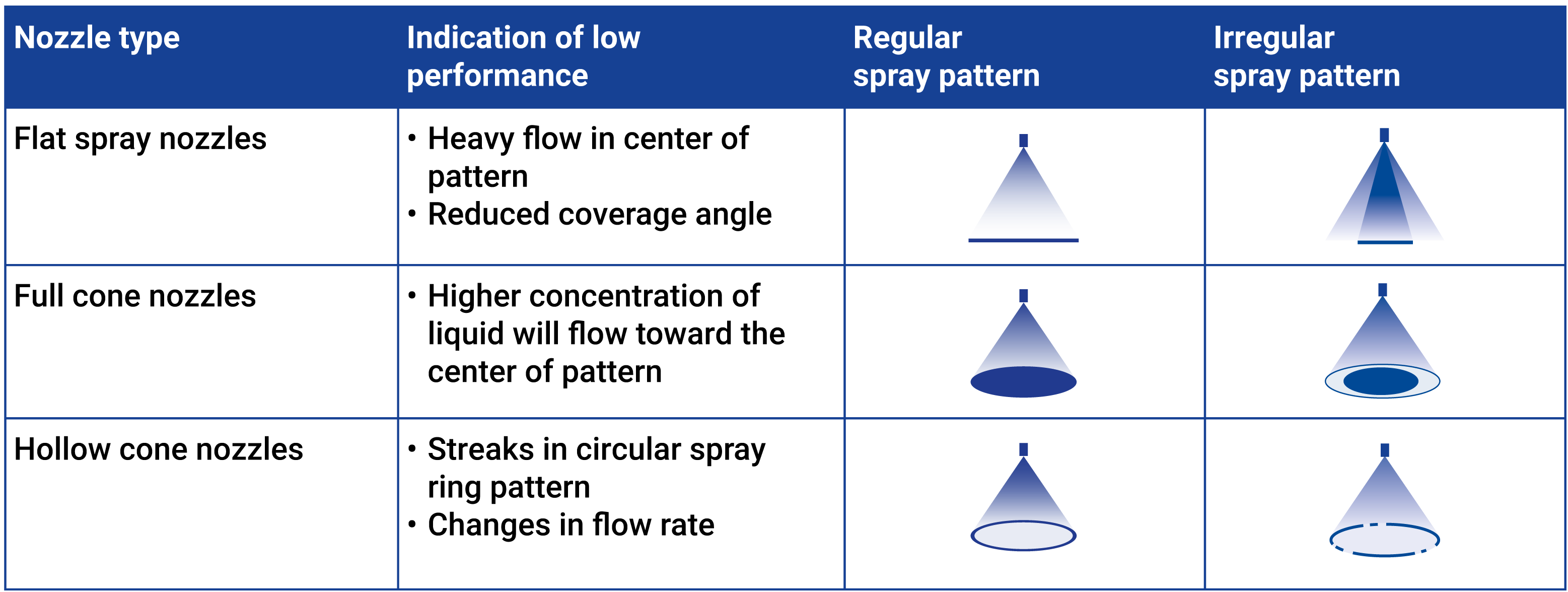

Nozzle cleaning should be done on a regular basis but with proper care. Only use plastic bristle brushes, wooden or plastic probes when cleaning nozzles. Avoid using wire brushes and metal knives because these can damage the nozzle orifice shape, resulting in poor spray performance. If the nozzle is clogged, soak the nozzle in a non-corrosive cleaning chemical, which will soften and eventually dissolve the particulate matter. - Detect irregular spray patterns

- Schedule routine maintenance

Nozzles should be inspected on a regular basis and be a part of your standard operating procedure. The most common routine nozzle maintenance procedures involve:- Check nozzle alignment

- Inspect nozzle damage

- Check spray pattern quality

- Monitor changes in flow rate

Contact

Lechler Spray Technology Sdn. Bhd.Phone +603 6142 1288 (General Line)Fax +603 6156 1153info(at)lechler.com.my