Spray headers for the steel industry

Lechler spray headers are more than pipes and nozzles. Because spray engineering is not only limited to nozzles – it is also about the optimum nozzle arrangement on the headers besides selecting the correct nozzle. Lechler covers the complete spectrum starting from the development of the spray nozzle, to measuring the spray performance over the application engineering and finally the header carrying the spray nozzles.

We designed spray nozzle installations in continuous casters, rolling mills, processing lines or in gas cleaning around the world with our proven software models for spray applications and also realized the engineering and fabrication of the spray headers.

The three cornerstones of Lechler spray headers

Process know-how

Decades of experience in successful planning and execution of projects in the metallurgical industry. Experienced engineers carry out mill studies and optimization proposals utilizing Lechler application software models.

Craftsmanship

Lechler wholly owned header engineering and fabrication facilities in India, USA, China and England serving the metallurgical industry. Process industry standard engineering, fabrication and QA procedures securing correct nozzle alignment for best spray result.

Nozzle portfolio

Europe’s No. 1 manufacturer of spray nozzles and technology partner offering the metallurgical industry with a wide variety of spray nozzles, standardized or tailored, for every process.

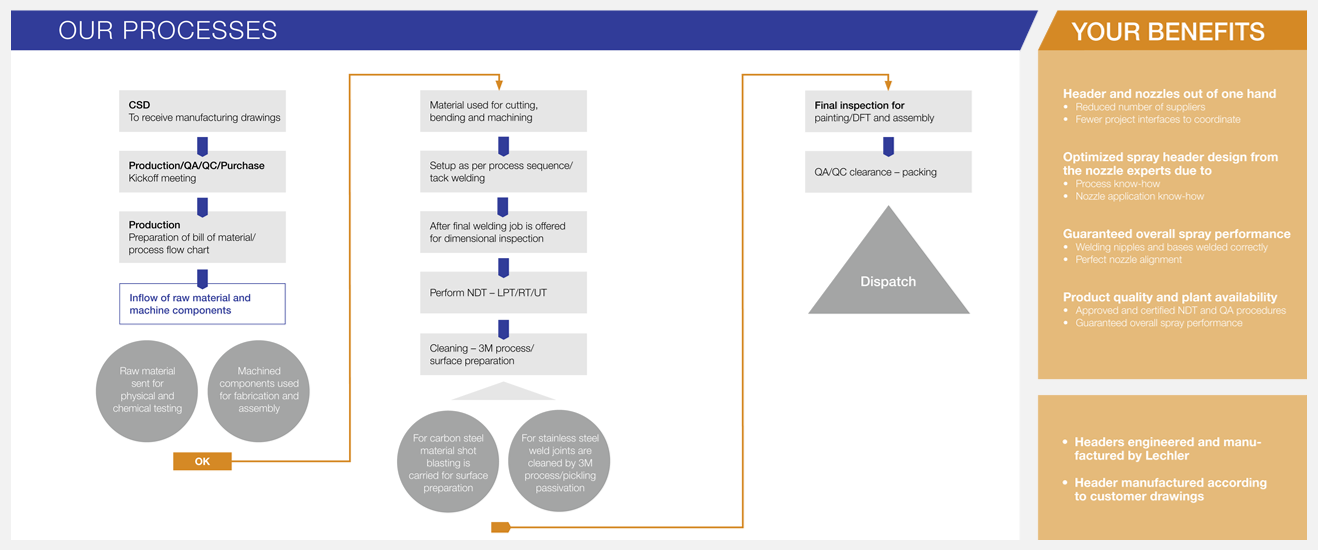

There is no shortcut when it comes to quality

Customers who demand an optimal spray result are leaving it to Lechler that every nozzle is perfectly aligned and positioned on a spray header. This goes for both, header manufacturing according to a customer drawing, and for headers engineered by Lechler.

Transparent processes, audited and certified by world leading plant engineering companies, Lechler spray headers and other fabricated structures undergo dedicated QA procedures from production planning, dimensional control prior and during fabrication, NDA-testing to factory inspection reporting (FIR), packing and shipping.

We've got the tools for perfect results

Our welders are on fire

The welding process in header manufacturing depends on the header design and material of construction. Based on the competence and experience with those special processes and their specific requirements, Lechler is assuring the high quality of every weld.

The Lechler engineers, welders, NDT personnel, welding inspectors and welding coordinators do receive frequent training according to international standards and do meet all required qualifications. Independent bodies are providing the welding certifications in accordance under high compliance standards.

SMAW Welding

Shielded Metal Arc Welding (SMAW) is the most popular welding process often used to weld carbon steel, low and high alloy steel, stainless steel and cast iron. It is a manual arc welding process that uses a consumable and protected electrode of a proper composition for generating arc between itself and the parent work piece.

TIG Welding

Tungsten Inert Gas (TIG) welding affords greater control over the weld area than other welding processes. TIG Welding is ideal for high quality and precision welding. It is often used to make root or first pass welds of piping of various sizes.

MIG Welding

Metal Inert Gas (MIG) welding is a versatile technique that uses a continuous solid wire electrode heated and fed into the weld pool from a welding gun. It is used for continuous welding of thick and thin section components. Being a semi-automatic process it provides a uniform and also a slag free weld bead.

Quality tests after welding

As important as welding itself are the methods and processes of nondestructive testing NDT of the material, the welds and the final header. Either performed according to customers special QA specifications or according to the internal Lechler NDT standards, no header is leaving a Lechler factory without a test certificate.

Hydro testing: Components such as piping systems, pressure vessels are tested for strength and leaks by hydro testing. Hydro test is carried out after completion of all fabrication work. Calibrated gauges are used for hydro testing which is carried out as per hydro test procedure.

Radiographic testing: Radiography (X-ray) uses X-rays and gamma-rays to produce a radiograph of a specimen, showing any changes in thickness, defects (internal and external), and assembly details to ensure optimum quality in operation. It is mainly used for volumatic inspection to find both surface and sub-surface defects. Radiographed film is evaluated by qualified professionals to take corrective measures.

Ultrasonic testing: In this process high frequency sound waves are transmitted into a material to identify changes in the material properties. Ultrasonic testing uses sound waves to detect crack and defects in parts and materials. Ultrasonic testing is often performed on steel and other metals and alloys. This process has greater accuracy than other non-destructive methods. Operators are trained to set up a test with the aid of appropriate reference standards and properly interpret the results.

Liquid penetrant testing: This method is used for detecting surface discontinuities. LPT is used to detect casting, forging and welding surface defects such as hairline cracks, surface porosity, leaks in new products, and fatigue cracks on in-service components. The process involves activities like pre-cleaning, application of penetrant, application of developer, inspection and post cleaning carried out by trained operators and inspectors.

Product Overview Spray Headers

Spray headers for secondary cooling in continuous casting

Headers made by Lechler for secondary cooling zones in continuous casting machines.

Spray headers for high-pressure descaling

On request, we design and manufacture complete spray headers for descaling processes according to your requirements.

Spray headers for roll cooling

On request, Lechler manufactures spray headers for hot rolling mills and cold rolling mills.

Spray headers for pickling and processing lines

Lechler supplies spray headers for spraying applications in processing lines for strips and wire, such as washing, pickling acid spraying, rinsing and cooling, strip edge drying.