Technical aspects of air nozzles

What you should keep in mind when planning

Different compressed air nozzles are required depending on the application and ambient or operating conditions. With its wide range of air nozzles, Lechler offers the optimum nozzle solution for every task. The following criteria are helpful in selecting the right air nozzles.

Criteria for the nozzle selection

Spray pattern of air nozzles

Air is also discharged at a specific angle. However, this is not comparable with that of liquids.

Air expands when it is discharged from the nozzle orifice, which leads to the expansion of the jet. The spray angle is normally approx. 20°.

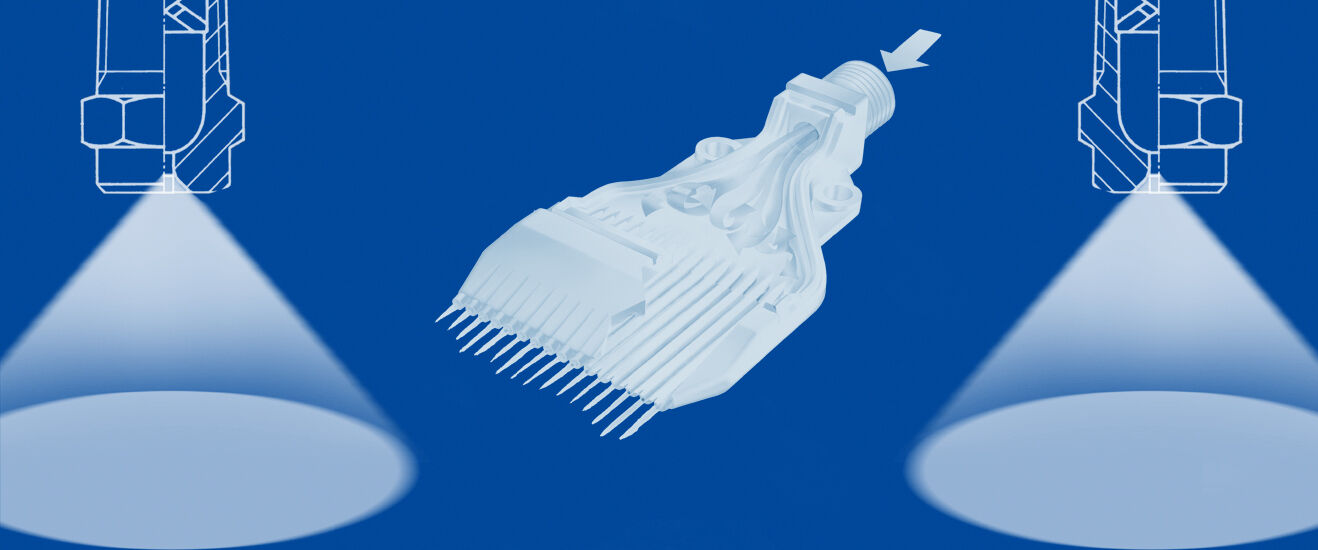

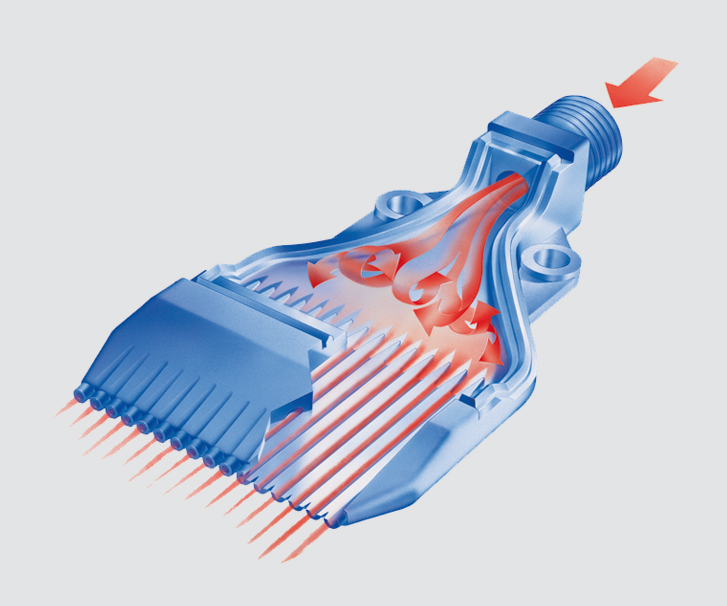

Innovative nozzle design

Conventional air nozzles:

- Air is blown through a narrow gap

- Turbulence results

- Loud hissing noises

Lechler multi-channel nozzle:

- Several flow-optimized air channels

- Reduced turbulence

- Uniform, targeted and powerful air flow

- Reduced noise development

- Reduced air consumption

Relationship between standard and operating flow rate

- Standard flow rate:

Unit quantity of gas at 101,325 Pa and 273.15 K

- Operating flow rate:

Flow rate under actual operating conditions

Exact calculation:![]()

p: Absolute pressure (atmosphere + system pressure = 1.013 bar + ps)

T: Absolute temperature (273.15 K + TMedium)

Figure to the left: Operating and standard flow rate at 298 K (+25° C).

Relationship between standard and operating flow rate at different pressures and constant temperatures.

Standard volume flow and operating volume flow

The term „standard volume flow“ refers to a unit quantity of a gas based on a standard reference. These standard conditions are used in nozzle technology, process engineering and other areas to compare gases on the basis of quantity information. If reference is made to standard volume flows in relation to nozzle technology, Lechler always bases its values on DIN EN ISO 1343.

In contrast, the term „operating volume flow“ describes the volume of the corresponding gas under the actual operating/application conditions. Since these normally differ from the standard conditions, pressure and temperature must always be clearly defined. If an operating volume is delivered in a certain time, this results in the operating volume flow.

Gases

The output of gases (e.g. air) is fundamentally different to the output of liquids. Gases are compressible fluids, whereas liquids are considered as incompressible fluids. Gases can be supplied with practically all nozzles that can also be used for atomizing liquids. However, due to the compressibility and lower density of gases, gas jets cannot be formed in the same way as with liquids.

Compressibility behaviour: Water (left), air (right)

Compressibility behaviour: Water (left), air (right)Gases tend to generate a significantly increased noise level under certain conditions (pressure and nozzle design). The development of multichannel nozzles with specially shaped nozzle orifices makes it possible to considerably reduce the turbulence in the nozzle that causes noise. In addition, this nozzle design increases blowing force while at the same time reducing air consumption. The speeds of gases can be very high under certain conditions. If a specific pressure difference is applied to a nozzle, speeds of approx. 320 m/s can often occur in the smallest cross section. This speed can even increase shortly after the gas leaves the nozzle.

Representation of the speed curve of outflowing air

Representation of the speed curve of outflowing airRecognized safety – Approval requirements fulfilled

The regulation (EC) No. 1935/2004: Regulation of the European Parliament for general safety requirements to all food and beverage contact materials.

OSHA (Occupational Safety and Health Administration): The US federal authority of accidents at work.