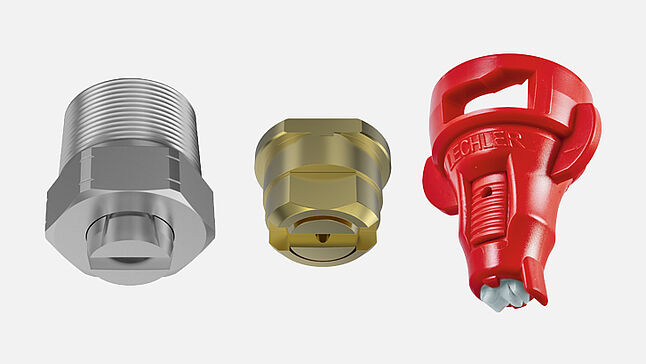

Flat fan nozzles

For an intensive and even (water) jet

The spray pattern of flat fan nozzles features a sharply delimited line due to internal flow characteristics. The coverage width can be varied by modifying the geometric configuration of the nozzle orifices. For all applications where an intensive and uniform water jet is required – such as cleaning processes, in the steel industry or many areas of surface technology – flat fan nozzles are the best choice.

The special geometry of the orifice outlet creates a flat, fan-like spray jet. Directly after leaving the nozzle, the flat liquid body takes on a laminar form and disintegrates into droplets as its distance from the nozzle orifice increases. Parabolic, trapezoidal or rectangular impact areas are achieved by adequately determining the functional and geometric dimensions.

Your benefits by using Lechler flat fan nozzles

- Excellent impact enables high efficiency

- Uniform liquid distribution and jet pressures

- Particularly powerful jets at spraying angles of up to 60°

- Flow geometry of the nozzle allows to produce accurate, compact jets

- Reliable documentation of nozzle performance data

Three advantages for you

Standardized and universal

Basically, Lechler flat fan nozzles are designed for parabolic liquid distribution. Unaffected by transient pressures, they are suited for universal application. Their performance data are exactly defined. Operational values, such as flow rates, spray width, jet thickness and liquid distribution are readily available for a great variety of feed pressures. Special-design nozzles with rectangular or trapezoidal distribution of liquid are available.

Cost efficiency

Simple and cost-saving fixing attachments, as for instance dove-tail guides and eyelet clamps, considerably facilitate assembling and aligning of the flat fan nozzles.

Service offer

A perfect solution must be optimally tailored to the requirements on site. We will be happy to advise you personally on the subject of flat fan nozzles and show you new possibilities. Talk to us and let us together lay the foundation for even more quality and optimized process reliability.

Anwendungsbeispiele für Flachstrahldüsen

Lechler flat fan nozzles are used in a variety of industries for a variety of applications:

Examples of industrial applications for flat fan nozzles

Application: Belt lubrication

Spraying a soapy solution (belt lubricant) onto the conveyor belt to lower the friction coefficient.

Your advantage:

- Less friction

- Economical and efficient consumption of belt lubricant

- Reduction of economic downtimes

Application: Circuit board manufacturing

Developing, etching and stripping of the resist in inner layer lines by using PVDF flat fan nozzles (» More)

Your advantage:

- Abrasion resistance of PVDF flat fan nozzles

- PVDF material suitable for harsh environmental conditions

- Temperature compatibility of PVDF material up to 140° C

Application: Washing installations

Cleaning in the pre-wash, main wash, sill and wheel washing as well as for wax application and rinsing . (» More)

Your advantage:

- Wide range of different flat fan nozzles for the respective section in washing installations

- Selecting the correct nozzle enables the cleaning result and water consumption to be balanced.

Application: Pre-treatment and painting systems

Water jet cleaning in pre-treatment and painting systems as well as washing up processes in rinsing zones and painting lines. (» More)

Your advantage:

- Water jet cleaning: Hard, sharp flat jet, limited spray pattern. Not prone to clogging.

- Installation possibilites: Maintaining of the adjusted spray direction when changing the nozzle.

- Rinsing zone: Easy, fast and toolless nozzle assembly.

Application: Automotive production

Cleaning in surface pre-treatment and spraying for leak testing.

Your advantage:

- Strong spraying effect at low pressure for efficient removal of impurities before series painting.

- Easy adjustment of the nozzles during rain tests for vehicles of different sizes.

Application: Part cleaning

Air nozzles arranged side by side at a small distance create a closed curtain. This air curtain cleanly blows off the objects during parts cleaning.

Your advantage:

- Closed air curtain due to overlapping jet zones

- Gentle barrier for dust and liquids

- Quality assurance in dirt-sensitive processes

Examples of metallurgical applications for flat fan nozzles

Application: Roll cooling

Single-fluid flat fan nozzles for cooling the rolls in rolling processes.

(» More)

Your advantage:

- Provision of a uniform homogeneous cooling across the roll width with a uniform, acceptable thermal distribution.

- Stable roll temperatures

Application: Descaling

Single-fluid flat fan nozzles for removing scale before rolling. (» More)

Your advantage:

- Increased quality and plant efficiency by effective descaling

- High jet power of descaling nozzles due to specific design as flat fan nozzles with particularly low jet depth

Application: Secondary cooling in continuous casters

Twin fluid flat fan nozzles for secondary cooling in continuous casting processes for slab plants for defined cooling and solidification of the steel strand. (» More)

Your advantage:

- Efficient and economical cooling of the strand surface

- Achievement of maximum productivity and optimum quality regarding continuous casting processes

Application: Pickling lines

Single-fluid flat fan nozzles for rinsing or spraying pickle for oxide layer/scale removal before cold rolling. (» More)

Your advantage:

- Effective pickling process to accelerate chemical processes resulting in optimum capacity of the entire pickling line

- Effective rinsing with even distribution of water jets

Examples of agricultural applications for flat fan nozzles

Application: Spike treatment

Preferred use of air-priming twin flat spray injector nozzles for spike treatment (» IDKT nozzle).

Your advantage:

- Optimum deposition on vertical target areas such as the spike area of plants

- Reduction of spray shadows in cloudy soil conditions

- Low drift, loss-reducing and environmentally friendly application

Application: Pre-emergence treatment

Extremely low-drift flat spray nozzle for timely application of pre-emergence herbicides (» PRE nozzle).

Your advantage:

- Up to 95% drift reduction in the pressure range of 1.5 to 5 bar

- High workrate through simple adaptation of l/ha rate and driving speed

- Gentle plant application due to extremely coarse droplet spectrum

Application: Sprinkling in greenhouses

(Multirange) flat spray nozzles for fine-droplet applications in greenhouses (» LU nozzle).

Your advantage:

- Optimum liquid distribution in the entire plant population

- Gentle plant application due to fine droplet spectrum

- Efficient irrigation

Application: Sprinkling of riding arena floors

Flat fan nozzles are predestined for sprinkling riding arena floors from the hall ceiling or by a spraying device at the floor (» ID3 nozzle).

Your advantage:

- Reduced risk of accidents due to optimally moistened riding floors

- Avoidance of overloading the tendons, muscles, ligaments and bones of horses

- Significantly reduced respiratory stress for horse and rider due to reduced dust generation

Application: Liquid fertilization

Flat spray nozzle with horizontal spray pattern for uniform cross-distribution at liquid fertilization applications (» FD nozzle).

Your advantage:

- Minimum risk of crop scorching due to extremely coarse-droplet application

- Gentle liquid fertilizer application thanks to extremely low spray impact

- Avoidance of streaking in the plant bpoulation due to optimum cross-distribution

Flat fan nozzles: Technical aspects and product porfolio