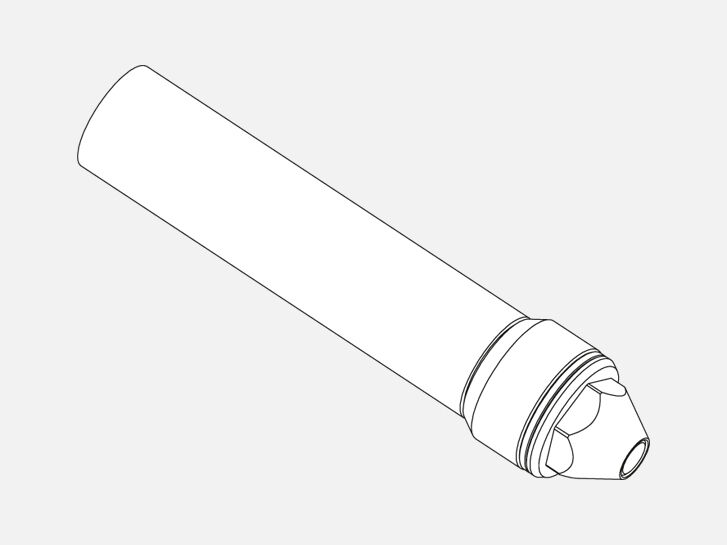

Laval Nozzle Lances

Special twin-fluid nozzles for DeNOx applications.

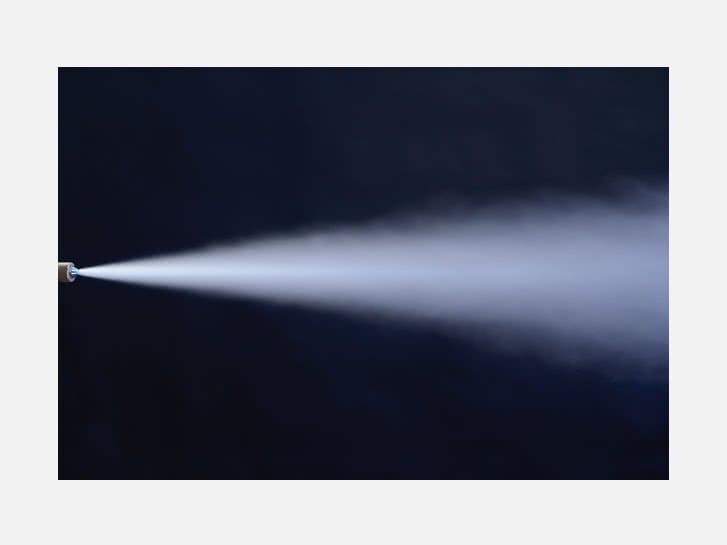

In DeNOx applications with SNCR processes, small Laval nozzles are usually used. These nozzles are characterized by a high discharge velocity, enabling the optimum droplet spectrum to be introduced into the reactor with a great penetration depth. Our research has shown that the discharge velocity has a greater effect on the denitrification process. Moreover, these nozzles without internals are extremely insensitive to clogging and can be precisely controlled.