Droplet separator systems on ships

Droplet separators are used on ships in a wide variety of applications. The droplet separators protect downstream ship plant components, reduce energy requirements or help to comply with legal environmental regulations.

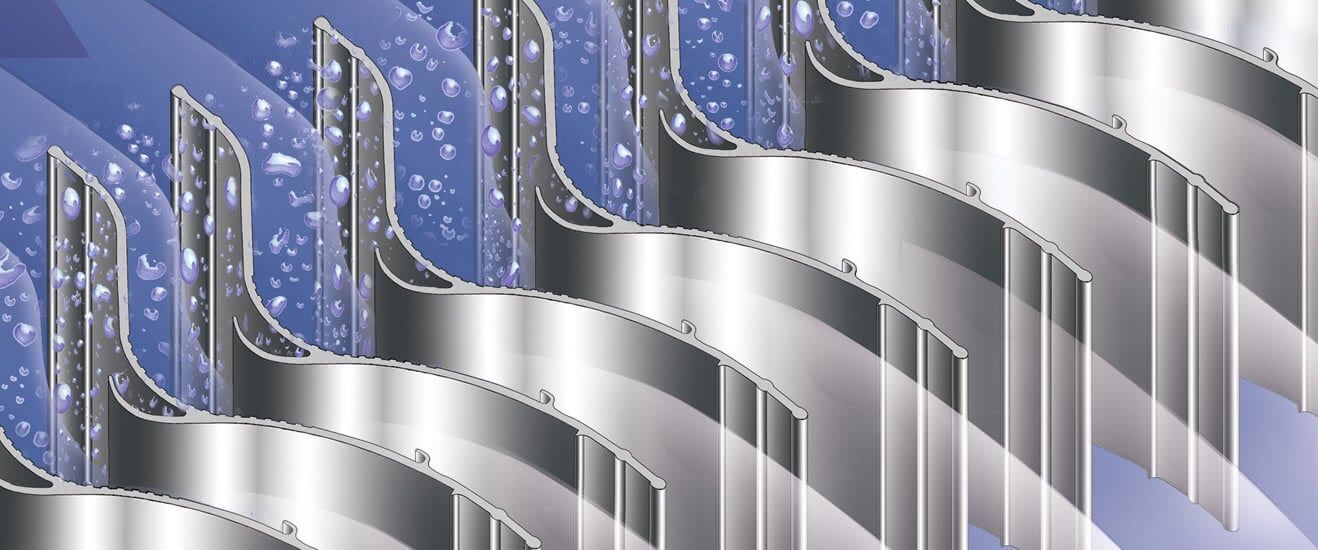

Possible areas of application are air intake systems as protection against rain and splash water or for the treatment of combustion air from engines. A further task is the use in the wet cleaning of exhaust gases to reduce the sulphur content. The use on ships therefore places high demands on the droplet separators.

The task of droplet separators on ships:

- Use in wet scrubbers for cleaning exhaust gases

- Protection of downstream systems

- Reduction of operating costs

Advantages of Lechler droplet separator systems:

- Modular design of the systems

- Highest separation efficiency for large quantities of liquids

- Separation of small droplets

- Compact design, even at high gas velocities

- Low pressure losses

- Uniformity of the flow distribution

- Can also be used for high quantities of solids

- Cleaning during operation

- Delivery of an overall concept

- Nozzles for the desulfurization of flue gases

- Droplet separators

- Integrated cleaning systems for droplet separators

The available materials include:

- Stainless steels in the grades 304 SS, 316L SS, 316Ti SS, 318LN SS, 904L SS, 254SMO SS as well as special alloys such as Alloy 22

- Plastics such as PP, PPTV, PE, PVDF

For the design and project planning of droplet separators, precise knowledge of the functional and performance data of the separator systems is required, as is a thorough understanding of the process technology for the respective application. The knowledge of droplet generation and droplet movement in a gas stream is essential for the optimal design of a droplet separator. For more than 100 years we have been dealing with the recognition, measurement and definition of droplets. It is not without reason that Lechler nozzles and Lechler droplet separators have become indispensable in process engineering and on ships.

Each plant requires a specific design and construction of the droplet separator. The design, construction and selection of Lechler droplet separator profiles is based entirely on your requirements, specifications and drawings. That is why we do not offer standard solutions, but put together individually the systems suitable for you.

In order to guarantee a flawless functional sequence, the materials used must be matched to the influencing variables of the individual system. For this reason Lechler offers a wide range of materials - also as stock goods.

Depending on the direction of flow, Lechler high-performance separators are divided into models for horizontal and vertical inflow. The choice of the flow direction depends on the process engineering and the design. Lechler offers you a suitable solution for all installation situations.