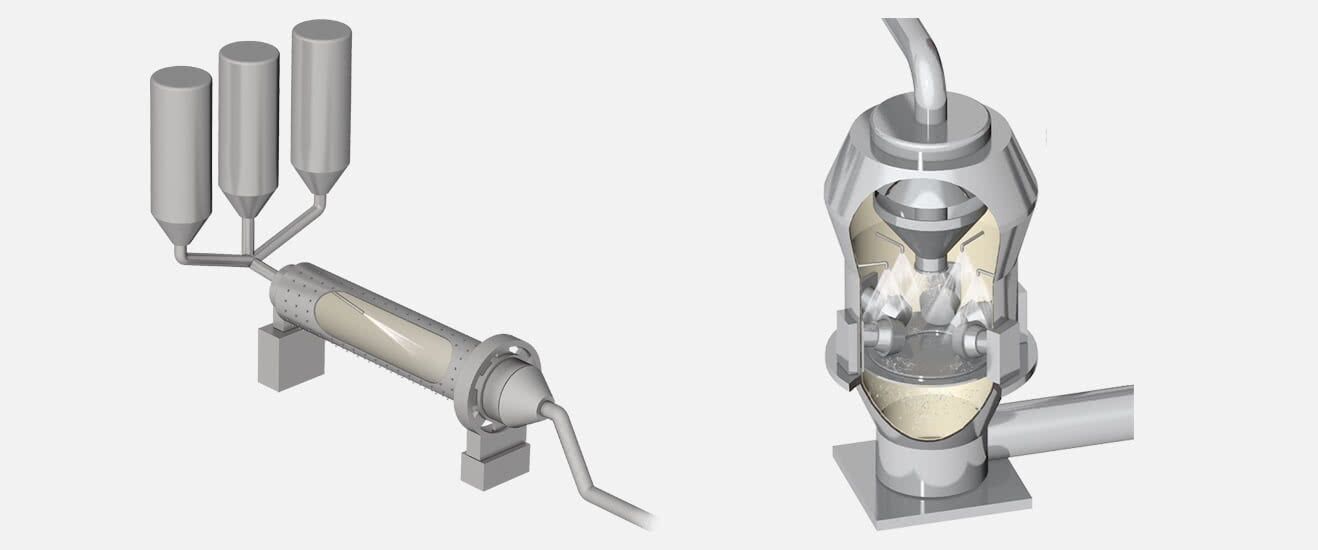

Ball mill and roller mill

Temperature reduction and process optimization in the mill.

Heating during the grinding process can decrease the quality of the ground material. Through the injection of water into the ball mill, excess heat is dissipated and the outlet temperature is kept at the desired level. Only if overtemperatures can be reliably avoided, the ground raw material or the ground cement can be safely and efficiently conveyed and stored. In the case of roller mills, the grinding bed is stabilized by the injection of liquid, thus optimizing the grinding process.

Our solution

We usually recommend single- or twin-fluid systems for injection, optionally fitted with rotary feedthroughs for the lances.

Corresponding products

Nozzle lances and systems for gas cooling

Efficient cooling and conditioning

Lechler nozzle lances and systems to generate the optimum droplet size range and distribute it as uniformly as possible in the gas flow.

Contact