Spray dryers

Professional disposal of residual and waste water

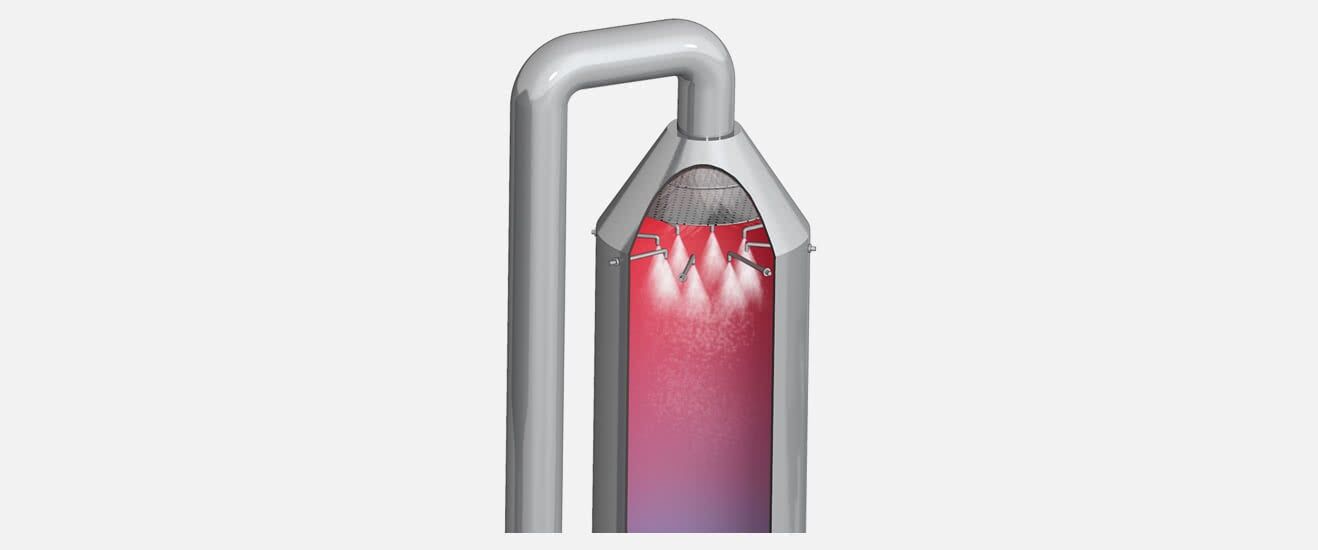

Spray drying is a method of drying solutions, suspensions or emulsions. With the regulation of waste water free plants it is necessary to integrate spray dryers as part of industrial flue gas cleaning. The primary task of spray dryers is the cost-effective, reliable and space-saving disposal of waste water. The resulting liquids are usually neutralized and then injected into the hot and to be cooled gas flow. After the liquid has evaporated, the solid and dry evaporation residues can be separated in the downstream filter.

Our solution

For the injection of suspensions we recommend our clogging resistant Laval nozzles with a large free cross section. Due to the very fine droplets produced by these nozzles, evaporation distances can be kept to a minimum. The nozzles are available in a variety of materials. This ensures that the optimum material is selected for each medium in terms of wear and lifetime.

In combination with our injection system, we offer you the optimum solution for your process requirements. Our online cleaning system enables very long operating times and a reliable and cost-optimized operation of the injection system due to the cyclic and automated cleaning of the nozzle lances.

Corresponding products

Nozzle lances and systems for gas cooling

Efficient cooling and conditioning

Lechler nozzle lances and systems to generate the optimum droplet size range and distribute it as uniformly as possible in the gas flow.

Contact