Videos General Industry

The following product and functional videos demonstrate the spra character or the fan shape of Lechler precision nozzles for General Industry as well as their functionalities:

Product videos tank and equipment cleaning

Lechler tank and equipment cleaning nozzles are the best choice for thorough cleaning of all possible types of tanks. The product videos show the functionalities and properties of these nozzles. The cleaning efficiency classes (CEC 1 – 5) allow a quick, optimal nozzle selection according to the type of contamination.

For small to medium tanks. Powerful full stream for cleaning of plants, containers, machines, e.g. in the food and beverage industry or the chemical industry.

The RinseClean spray ball can be used in areas with high hygienic requirements and high temperatures. It is available with various slip-in connections, as well as in threaded or welded versions.

Very inexpensive, self rotating, effective flat jets. Cleaning of machines, plants, tanks, e.g. beverage, food and pharmaceutical industry.

Very inexpensive, self rotating, effective flat jets. Cleaning of machines, plants, tanks e.g. beverage, food and pharmaceutical industry.

The rotating cleaning nozzle NanoSpinner 2 is part of the new spinner generation. With improved spray performance, hygienic design and a distinctive surface finish, it is a proof of high quality.

The rotating cleaning nozzle MiniSpinner 2 is part of the new spinner generation. With improved spray performance, hygienic design and a distinctive surface finish, it is a proof of high quality.

The newly developed MaxiSpinner 2 convinces with effective cleaning results and a reliable as well as durable bearing construction.

Self rotating, rotating solid jets, recommended for tanks made of glass and enamel. Cleaning of machines, plants, tanks, e.g. food, chemical and pharmaceutical industry.

High functional reliability during operation with liquids/foam from detergent/water mixtures, low water and detergent consumption. For applications with special sanitary requirements.

The new powerful rotating cleaning nozzle Whirly 2 stands for uniform, fast and reliable cleaning. With the HygienicFit, it offers a unique hygiene concept.

The Gyro cleans with powerful nozzle inserts and is available in many flow rates and spray angles. It is also suitable for very large tanks and is insensitive to clogging.

Specially developed flat fan nozzles provide high impact and uniform cleaning for the XactClean HP. The controlled rotation ensures that the XactClean HP 2 works extremely efficient.

The XactClean HP+ is made for higher flow rates and offers addiotional power especially for bigger tanks. Based on the successful functional principle of the well known XactClean HP.

The high impact cleaning machine MeshClean enables a very efficient cleaning of containers and machines. Thanks to powerful solid jets it can solve even the most difficult cleaning tasks.

Outstanding technology set in scene: the key features of the MeshClean at a glance.

The MeshClean+ is extremely effective thanks to the particularly powerful solid jet nozzles and is suitable for medium to large tanks with persistent soiling.

For medium and large tanks. The gear-driven 5TM has particularly powerful full jets. For cleaning machines, plants, tanks, road tankers, big tanks, e.g. beverage, food chemical and paper industry.

The new high pressure tank cleaning machine PressureClean removes the most persistent soiling from small tanks with low water consumption.

If a certain fluid pressure is reached, the rotating cleaning nozzle of the PopUp Whirly automatically moves out of the housing. Installation flush with the tank wall. Effective flat jet geometry.

Product videos spray drying

For spray drying, the Lechler DryMASTER series with its unique modular concept offers hundreds of application possibilities in the food and drug industries.

The DryMASTER series is the master class of spray drying – modularly designed with hundreds of application possibilities. Demonstration of nozzle assembly step by step.

The compact, reliable DryMASTER check valve – easy to screw into spray lances to opitimize process safety or product quality. Step-by-step assembly demonstration.

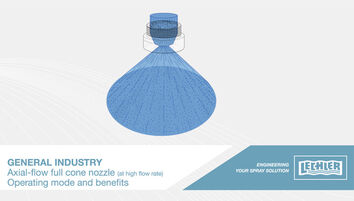

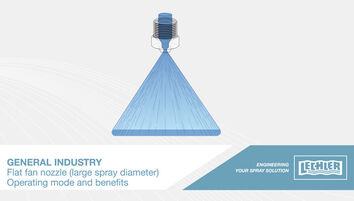

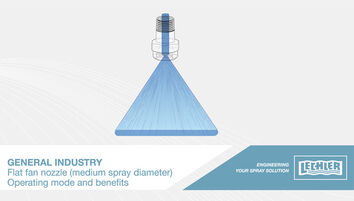

Functional videos industrial nozzles

How does a flat fan, hollow cone or full cone nozzle spray? These videos explain the functionalities, the spraying behavior or the fan shape of different nozzles as well as their advantages.

This video shows the spray pattern and the advantages offered by an axial hollow-cone nozzle with high flow-rate.

This video shows the spray pattern and the advantages of an axial-flow full cone nozzle with high flow-rate.

This video shows the spray pattern of a flat fan nozzle with large spray diameter and the advantages offered by this nozzle.

This video shows the spray pattern of a flat fan nozzle with medium spray diameter and the advantages offered by this nozzle.