FAQs – Frequently asked questions and answers in the industrial sector

Frequently asked questions about the use of Lechler nozzles and nozzle systems in the industrial sector and the corresponding answers can be found in the following compilation.

Overview of questions:

- Why do nozzles have different spray patterns?

Nozzles are used in a wide variety of applications. Therefore nozzles have to meet a lot of different requirements. One of those requirements is applying the right spray pattern for a specific application.

A nozzles spray-characteristics are basically influenced by:

- the geometric design of the nozzle outlet

- the medium properties (specifc gravity, viscosity)

- the internal geometry (swirl part, swirl chamber)

- the supply of the medium (axial- or tangential flow)

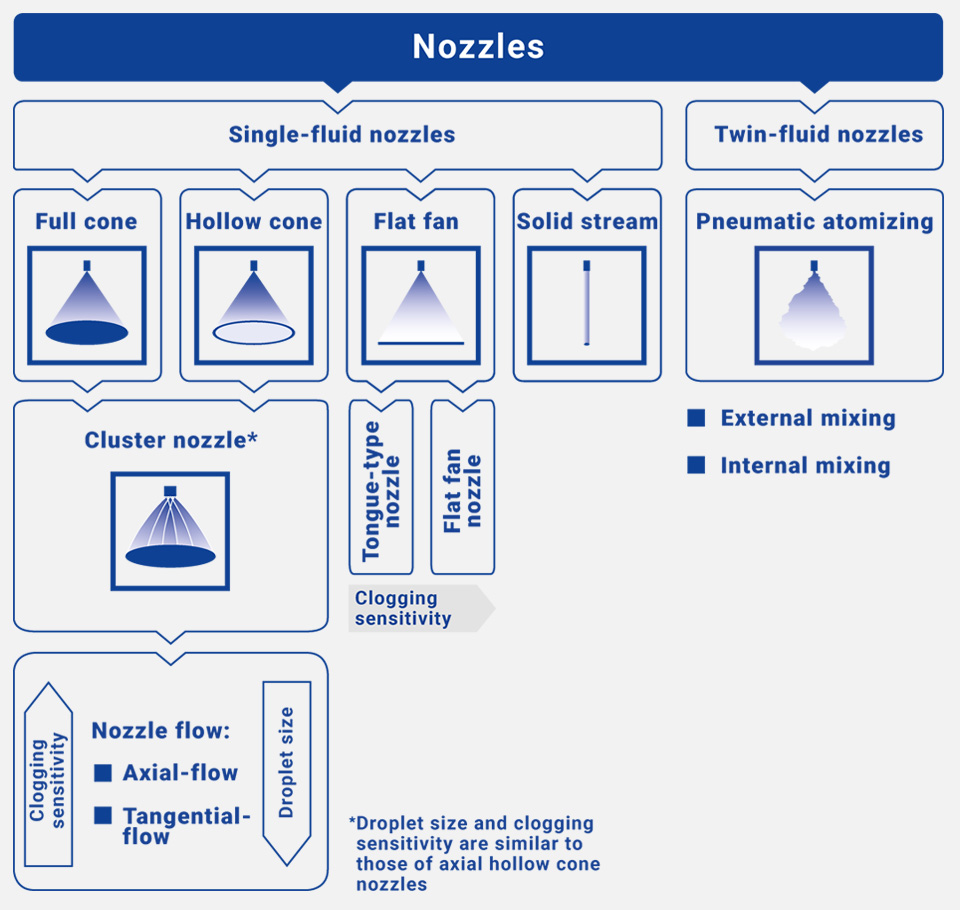

For this reason there are different nozzle types which can be categorized as follows:

- What is atomization and which methods are applied?

Atomization occurs when a liquid jet is broken down into more or less fine droplets. The ideal spray consists of drops of the same diameter. Atomization methods can be divided into hydraulic atomization and pneumatic atomization.

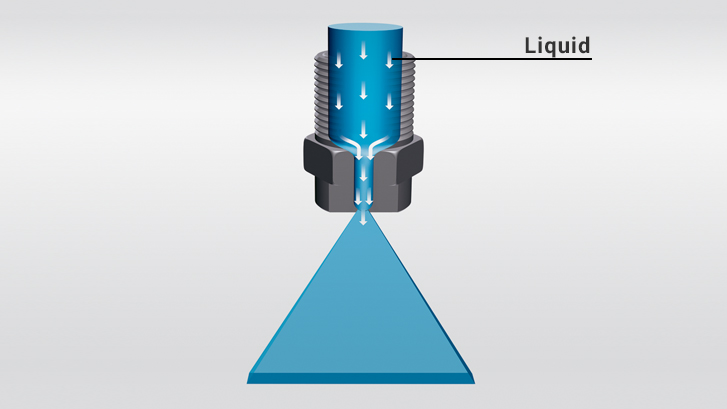

Hydraulic atomization:

A media passing through a nozzleincreases in speed as the cross section diameter becomes smaller. Potential energy becomes kinetic energy (velocity). After the medium passes through the nozzles orifice, it develops an aerodynamic wave pattern, which later leads to droplets in different sizes.

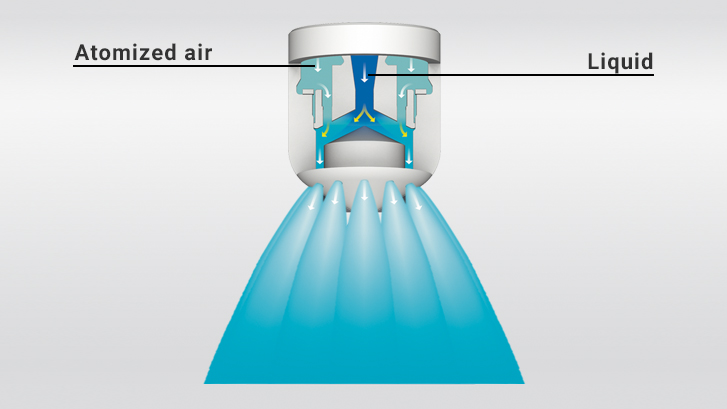

Pneumatic atomization:

This atomization method achieves the highest degree of atomization: the finest droplets. Under certain conditions, the droplets can completely evaporate. Pneumatic nozzles can be used, for example, to atomize more viscous media than water. A distinction is made between internal and external mixing pneumatic nozzles.

- Which spray character suits which application?

In addition to the classification by atomization principles, nozzles are also classified by their spray patterns. Characteristic spray patterns are:

Hollow cone spray

Circular hollow cone for uniform, fine, ring-shaped droplets. For gas cooling / gas cleaning, dust control, product dampening.Full cone spray

Circular solid cone for uniform droplet distribution in the spray jet. For washing / cleaning applications, chemical processes, for fire protection.Flat fan spray

Linear impact with uniform liquid distribution. For cleaning applications in the steel industry or surface technology.Solid stream

Compact, clearly defined jet without atomization. For cleaning processes, during cutting operations and for punctiform jet impacts.Dispersion of compressed air

Concentrated, targeted discharge of air or saturated steam. For drying, cooling, cleaning, conveying, cleaning or mixing.Atomization for tank cleaning

Static or rotating (partly self-propelling) nozzles. For internal cleaning of small containers up to large tanks.Pneumatic atomization

The finest atomization possible by mixing liquids with air or gas. By combining interchangeable air/liquid caps, flat jet, hollow cone or full cone spray patterns can be produced with twin-fluid nozzles. For cooling, disinfection, coating, spray drying, product humidification / air humidification. - Which tightening moment for nozzles / cap nuts?

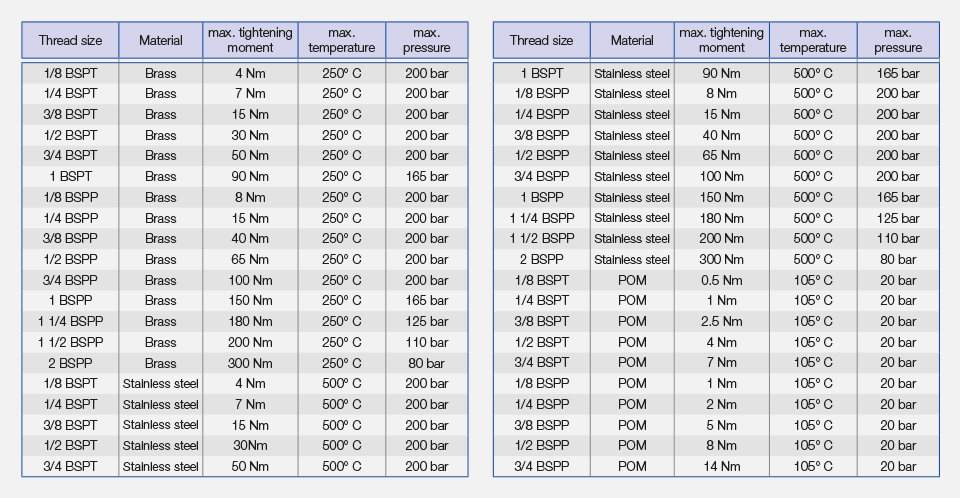

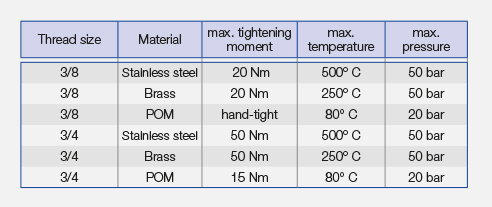

The following tables represent a guideline for tightening torques – for single-fluid nozzles and cap nuts.

Low-pressure nozzles:

Connection type cap nut:

- How to optimally maintain and clean nozzles?

Nozzle maintenance should be a regular part of the production process to keep lines running efficiently. Lechler‘s Five Step Process for extending nozzle life provides information on causative factors for poor nozzle performance and what signs to look for when a nozzle is not spraying properly. Thus, significant quality problems and profit losses can be avoided.

Recommendations for extending nozzle life – Five Step Process:

- Change nozzle material

Environment can affect the material of a nozzle, which can cause erosion and wear. Selecting the proper material is critical to ensure longer nozzle life. Nozzle materials such as PTFE or PVDF work better than metals if corrosive chemicals are being sprayed. - Add line strainer or filter

Proper filtration can eliminate unwanted particulates, which can result in clogging and restricting nozzle flow. For this reason, a line strainer or built in nozzle strainer is recommended with a screen mesh size that will prevent particulates from entering the nozzle. For any questions regarding the correct mesh size, Lechler will be pleased to advise you. - Use proper tools and cleaning care

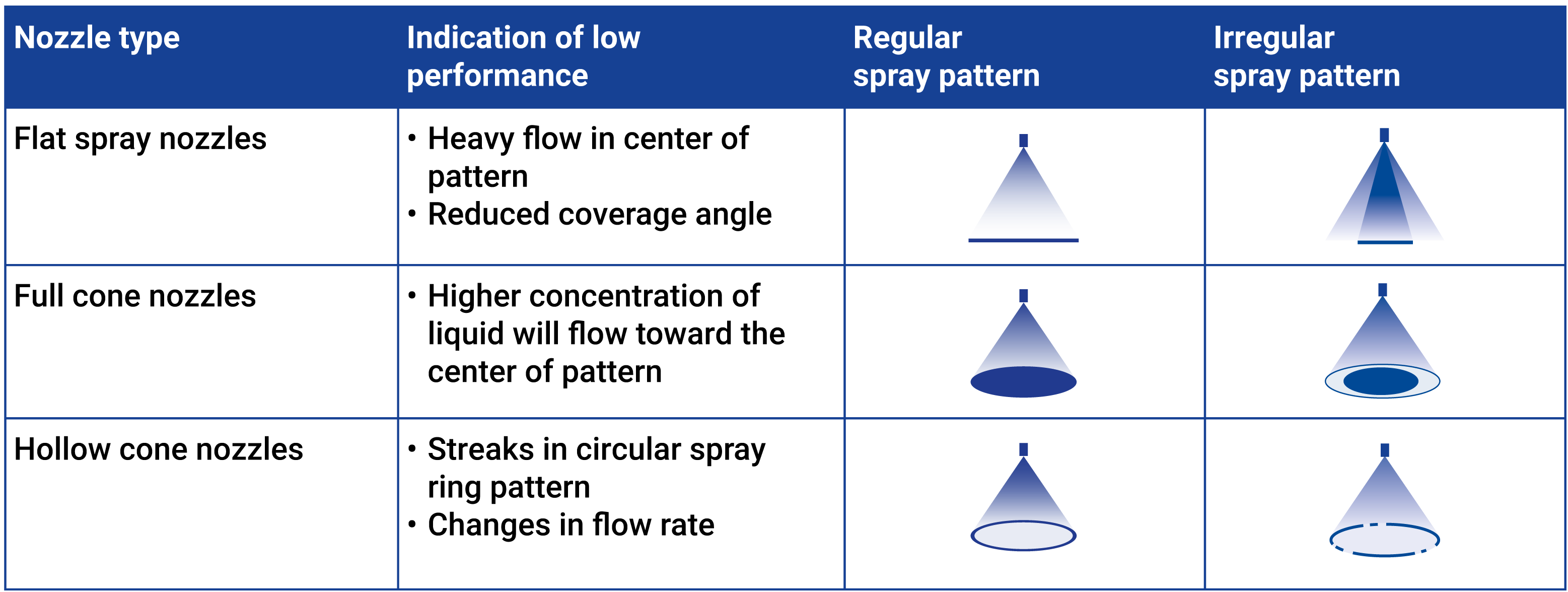

Nozzle cleaning should be done on a regular basis but with proper care. Only use plastic bristle brushes, wooden or plastic probes when cleaning nozzles. Avoid using wire brushes and metal knives because these can damage the nozzle orifice shape, resulting in poor spray performance. If the nozzle is clogged, soak the nozzle in a non-corrosive cleaning chemical, which will soften and eventually dissolve the particulate matter. Ultrasonic cleaners can also be used for nozzle cleaning. - Detect irregular spray patterns

- Schedule routine maintenance

Nozzles should be inspected on a regular basis and be a part of your standard operating procedure. The most common routine nozzle maintenance procedures involve:

- Check nozzle alignment

- Inspect nozzle damage

- Check spray pattern quality

- Monitor changes in flow rate

- Change nozzle material

FAQs Agriculture

We have summarized our FAQs in agriculture separately and clearly for you:

FAQs Agriculture