Steel industry

Precision for cool calculations.

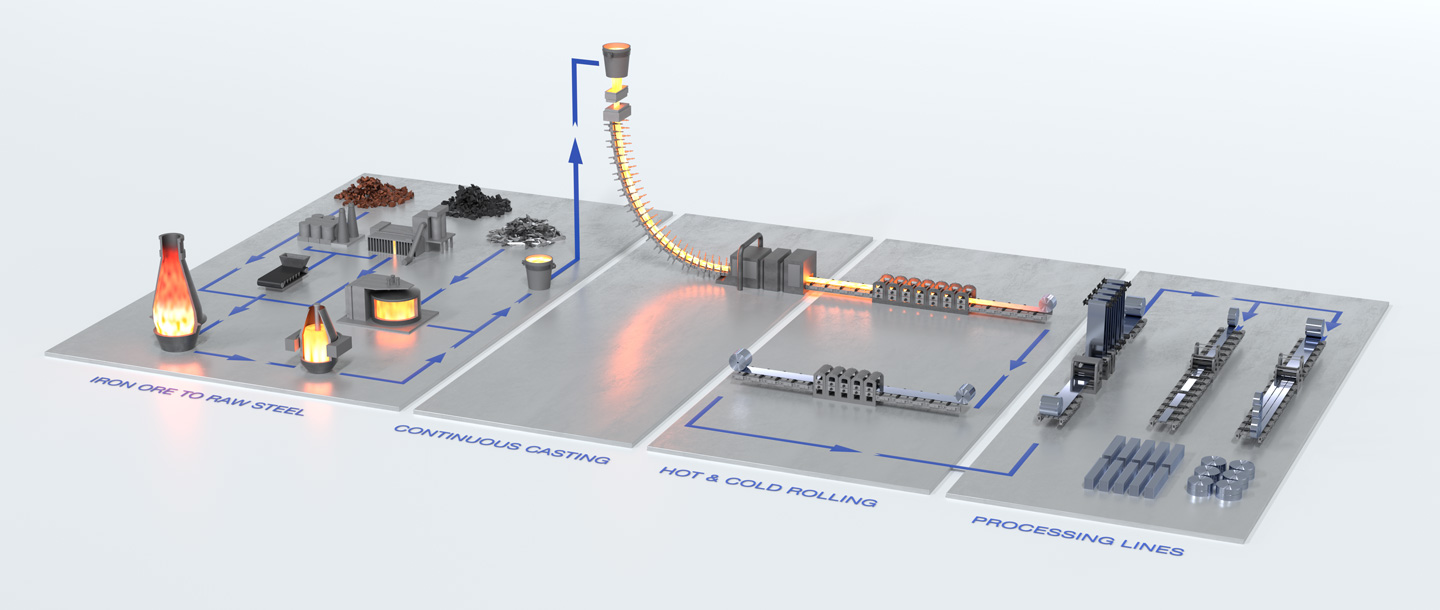

With special nozzles made of very different materials, Lechler offers a complete nozzle program for all spray applications in steel production. The range is wide, including casting, cooling, roll cooling, descaling and strip processing. The most important factor is the optimum result with the lowest possible use of energy and spray media - and therefore a significant reduction in the overall CO2 balance of a steel mill. Due to our in-depth understanding of the process, we are able to support steel mill operators directly in optimizing their steel quality. The bottom line is that Lechler provides for three distinct competitive advantages: lower costs, higher quality and increased efficiency. Talk to us.

Air quality control systems in the steel industry: Cool solutions for a hot market

Significant changes have been ongoing in the steel industry for many years now. Ever stricter emission regulations are creating a constant pressure to invest and innovate. Efficient gas conditioning offers a wide range of approaches to reducing costs and increasing efficiency. A prerequisite is that the respective processes are thoroughly understood and that gas conditioning is adapted accordingly.

We work together with you to develop the optimum solution for your specific application. We support you with comprehensive consulting services ranging from process analysis to turnkey solutions.

Lechler applications in steel mills at a glance

Professional reports