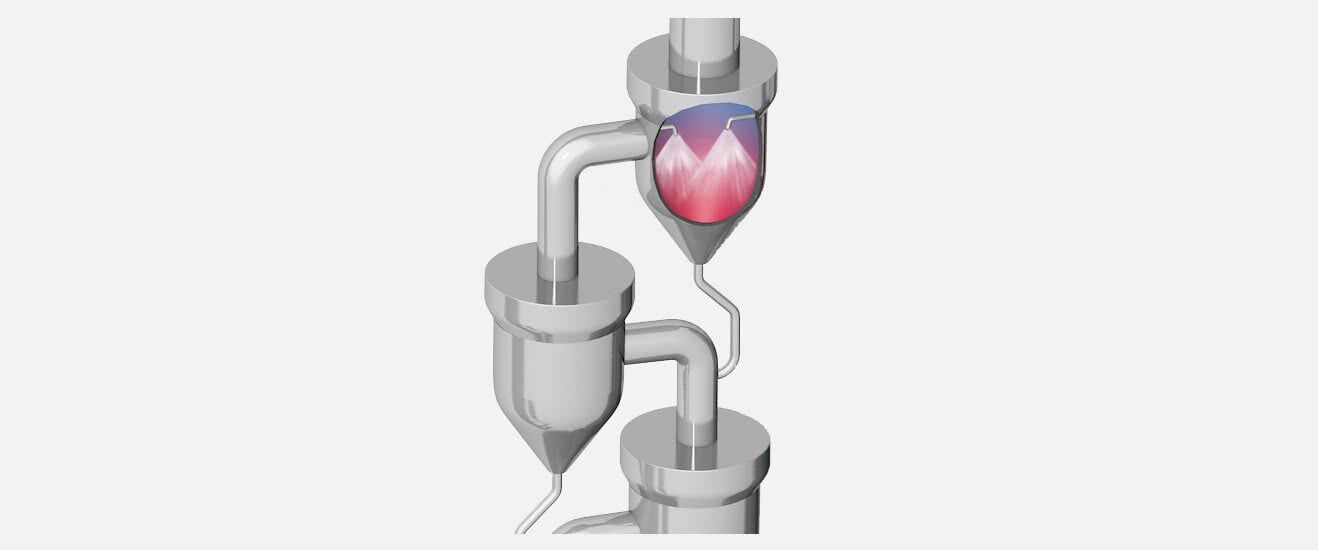

Cyclone preheater

Compensation of temperature peaks or additional cooling.

Additional cooling through injection into the top cyclone of the preheater gives you various advantages. On the one hand, it supports subsequent cooling in the duct or gas cooling tower, while temperature peaks can be compensated on the other.

The associated temperature reduction decreases the operating gas flow rate. This reduces the energy required by the downstream fan, which may also eliminate the need to exchange it. In addition, the efficiency of the cyclone is increased through the moistening of the raw material.

Our solution

Direct injection into the top cyclone is an effective way of eliminating temperature peaks. The high dust load and the resulting large surface area facilitate evaporation.

To enable a controlled water quantity to be introduced, we mostly use spillback systems.

Corresponding products

Nozzle lances and systems for gas cooling

Efficient cooling and conditioning

Lechler nozzle lances and systems to generate the optimum droplet size range and distribute it as uniformly as possible in the gas flow.

Contact