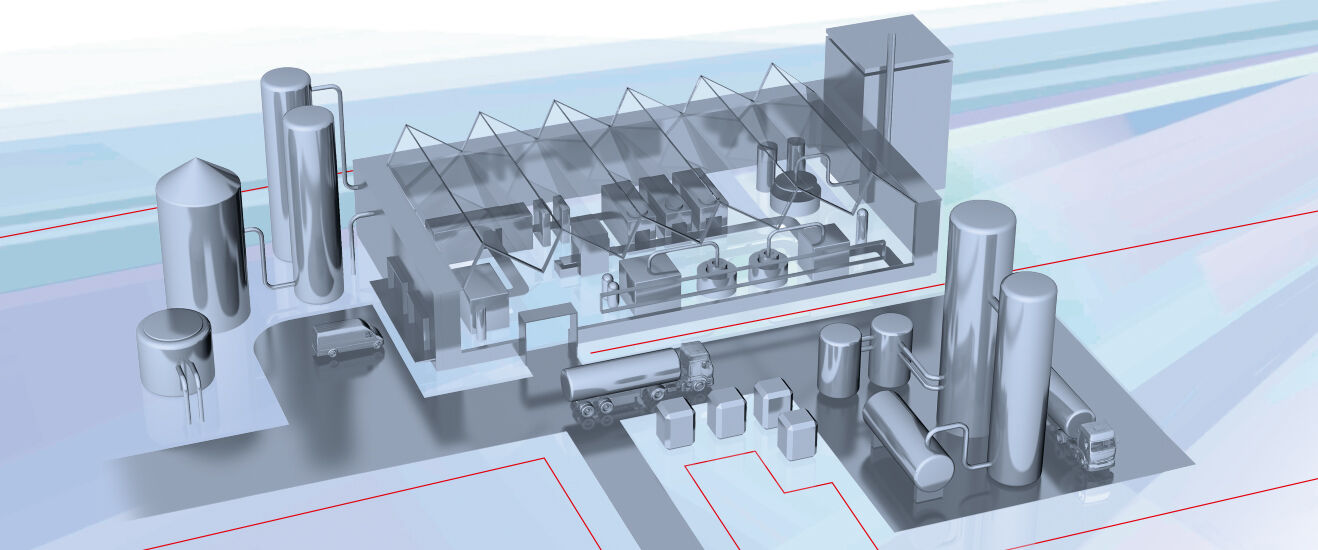

Tank and equipment cleaning

Cleaning nozzles for every container and tank size

Companies all over the world in a wide range of industries rely on Lechler tank and equipment cleaning nozzles for thorough cleaning of all kinds of tank sizes, machines and equipment. The Lechler tank and equipment cleaning nozzle range features innovative drive concepts, state-of-the-art nozzle design as well as a large choice of sizes and materials. The scope of our portfolio is unique to the market and offers the perfect solution for every application.

Lechler nozzles for tank and equipment cleaning

| For every application |

| Cleaning in Place (CIP) Many of Lechler‘s precision nozzles for tank and equipment cleaning are CIP-capable and can remain in the installation during the production process. |

| Hygienic equipment cleaning |

| The right nozzle for every tank Our extensive product range includes the right nozzle size for every application – from a small test tube to a large fermentation tank for bioethanol production. |

Your benefits:

- None of the risks, restrictions and costs related to manual tank cleaning

- Modern nozzle technology cuts cleaning fluidconsumption and reduces downtimes

- The cleaning process is trouble-free, repeatable and verifiable

Certifications and approvals for nozzle materials

Lechler precision nozzles – especially for tank and equipment cleaning – are made of extremely high-grade materials that are designed to meet high requirements such as resistance to cleaning chemicals or temperature influences. The large choice of different materials – e.g. 316L SS, PVDF, PEEK or PTFE – allows nozzle selection customized to the individual application and operating conditions. In addition, the materials used for the tank and equipment cleaning nozzles are perfectly matched to each other and are thus characterized by very low wear.

In addition to the requirements for material resistance and wear, the materials must also be food grade for use in the beverage, food and pharmaceutical industries. Depending on the application area, the materials must meet different demands. A large number of the materials used for Lechler tank and equipment cleaning nozzles comply with the requirements of the FDA or conform to (EC) 1935/2004.

Hygiene requirements

Lechler‘s tank and equipment cleaning nozzles are designed so that they meet hygiene requirements. This is reflected, for example, in the self-draining function, minimized dead space in the nozzles as well as an external design without unnecessary gaps and edges. At the same time, the nozzles are designed with the lowest possible surface roughness. Lechler also offers specially certified nozzles for particular hygiene requirements. The "PTFE Whirly" and 527 series are 3A-certified, for example.

Professional reports