Droplet separation

Custom-made reduction of pollutants

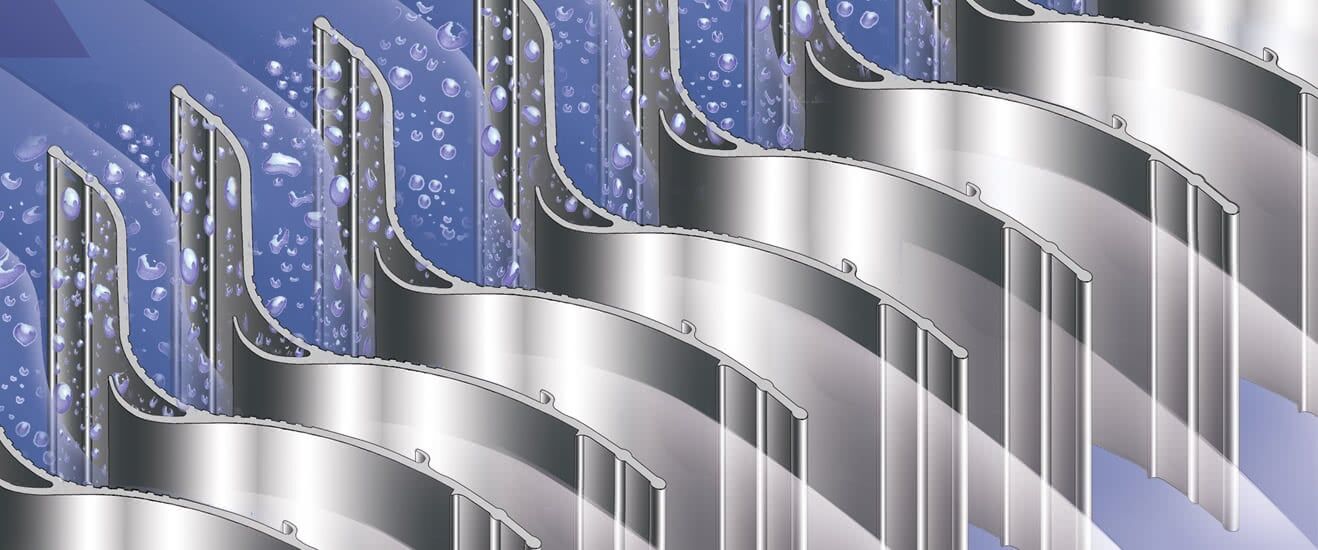

For the separation of liquid droplets from flowing gaseous media such as air or process gases, droplet separator systems are used as an essential functional element in process engineering technology and gas cleaning applications. Strict legislation on environmental protection requires the use of powerful droplet separators, which remove even the finest droplets with as little pressure loss as possible and drastically reduce the residual content of pollutants after gas scrubbing plants. Lechler offers custom-made droplet separator systems that can be aligned to individual requirements and can cope with high inflow velocities even at low installation depths.

Application areas

Droplet separation in shipbuilding

Lechler droplet separators in shipbuilding for compliance with environmental laws, e.g. for desulfurization by wet scrubbing and for charge air coolers.

Droplet separation in the chemical industry

Lechler droplet separators for minimizing undesirable emissions in process engineering and chemical plants.

Droplet separation in the Paper industry

Lechler droplet separators in the paper industry for optimizing energy efficiency through chemical recovery of used raw materials.

Droplet separation in the food and beverage industry

Lechler droplet separators for compliance with strict hygiene requirements in the food and beverage industry and to increase process efficiency.

Droplet separation in metallurgy

Lechler droplet separators for reducing process-related emissions in metallurgy and for protecting the environment as well as plant components.

Droplet separation in flue gas desulfurization

Lechler droplet separators for integrative holistic solutions with high-performance nozzles for flue gas scrubbing and droplet separators including cleaning system.

Droplet separation in wind turbines

Lechler droplet separators for the protection of downstream plant components in wind turbines and as a sustainable solution for climate protection.

Matching products

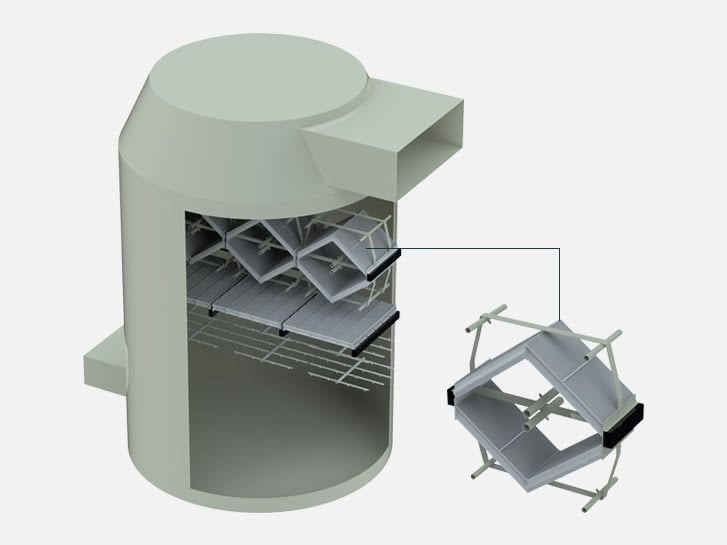

Lechler droplet separator systems

Modular, compact, combinable and efficient.

Different Lechler droplet separator systems can be combined with each other, depending on efficiency and space requirements.