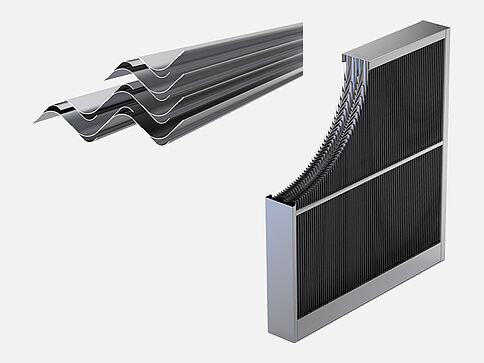

Lechler Droplet Separators

Modular, compact, combinable and efficient.

Lechler offers you a wide range of different separation profiles, which can also be combined with each other. This gives us the opportunity to find the optimal solution for your task. Ask us – we will find the suitable droplet separator system for your requirements in terms of efficiency and space. For your inquiry, please use our data collection sheet for droplet separators.

Overview of Lechler Droplet Separator Systems

Droplet Separator LTH 100

Droplet separator system with horizontal gas flow, available in different materials. Universally applicable droplet separator system that has proven itself over decades.

Droplet Separator LTH 500

Droplet separator system with horizontal gas flow, predestined for cramped installation conditions. Profile geometry with angled inlet and outlet.

Droplet Separator LTH 600

High-performance droplet separator system with horizontal gas flow for highest demands. Suitable for high flow velocities.

Droplet Separator LTV 271

Vertical-flow droplet separator system with standardized profile widths. Good separation performance with low pressure losses.

Droplet Separator LTV 300

Vertical gas flow droplet separator system with complex profile geometry for highest separation performance. Optimal for coping with high liquid volumes.

Droplet Separator LTV 400

Vertical flow droplet separator with high variability. Adaptable to different operating requirements and predestined for high dust loads.

Droplet Separator LTV 10 AA

2-stage droplet separator system with integrated cleaning system for installation on two levels.

Droplet Separator LTV 120 C

2-stage droplet separator system with integrated cleaning system for installation on one level. This system is optimized for restiricted installation spaces.

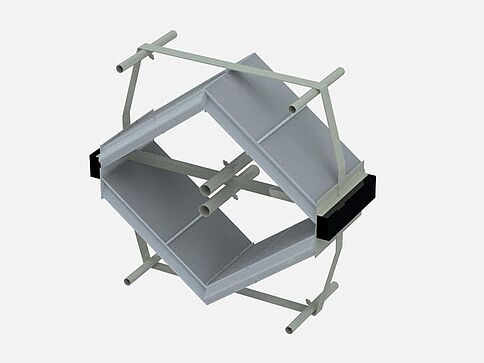

Droplet Separator LTV 120 CR

3-stage droplet separator system with integrated cleaning system for installation on two levels. The first separation stage consists of horizontally arranged pipes for pre-separation and flow optimization.

Droplet Separators LTV 120 + LTV 400

2-stage droplet separator system with integrated cleaning system for installation on two levels. The first separation stage consists of the LTV 400 as a flat separator level.