VarioJet II-3 nozzle: The new series for small liquid flow rates

The range of the proven Lechler VarioJet twin-fluid nozzles with low air consumption at a large outlet angle has now been extended: In addition to the series II-6 and II-8 the new series II-3 is now available, which is especially designed for small flow rates from 0.045 l/min to 10 l/min.

The new VarioJet II-3 nozzle series currently comprises five nozzles. Their suitability for small liquid flow rates of 0.045 - 10 l/min enables the extension of the Lechler product portfolio in this liquid range with nozzles that, compared to the Lechler Laval nozzles, produce fine droplets at small air/liquid ratios and have a large spray angle.

Fine droplets and a large spray angle are an ideal condition to accelerate heat and mass transfer processes. Shorter evaporation times for gas cooling or faster reaction times for the injection of ammonia water for DeNOx-systems are efficiency and cost-decisive factors here.

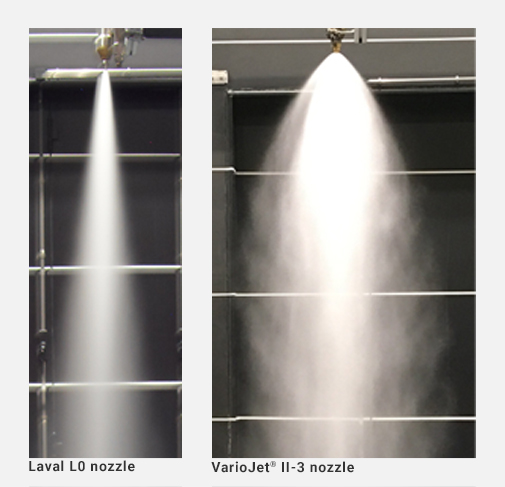

Spray pattern comparison between a Laval L0 nozzle and a VarioJet II-3 nozzle

| Laval nozzle L0 (left spray pattern) | VarioJet II-3 nozzle (right spray pattern) |

| Type 180.641 (15°) | Type 120.446 (90°) |

| 10 l/min water @ 5 bar air | 10 l/min water @ 6 bar air |

| (44 Nm³/h STA air) | (28 Nm³/h STA air) |

Advantages of the VarioJet II-3 nozzle at a glance

- Shorter evaporation times

- Faster reaction times during injection

- Reduced operating costs due to lower air volume consumption

- Large spray angle 60° and 90°

- Wide fluid control range from 27:1 to 50:1

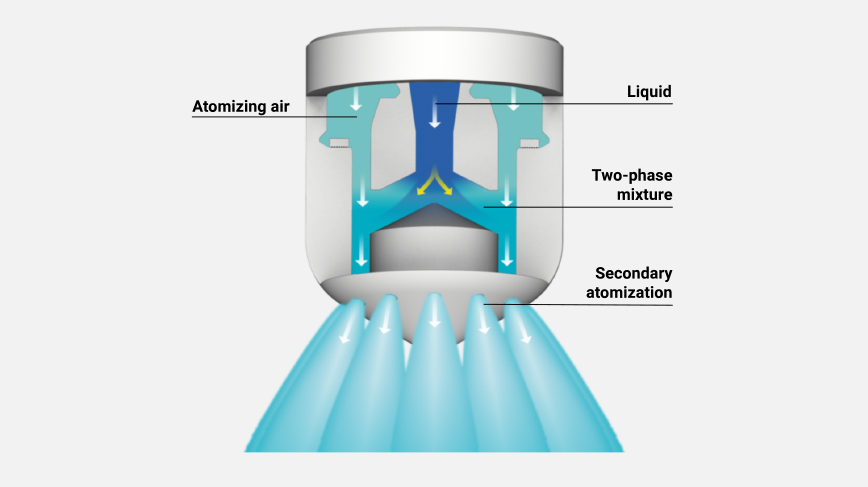

Principle of operation

Lechler VarioJet nozzles atomize according to the principle of internal mixing. With this twin-fluid nozzle, the water is fed in axially. After arriving at the distribution plate, the liquid is split up into a thin liquid film. This thin liquid film is split into finest droplets by the atomizing air in the mixing chamber. The resulting two-phase mixture is then atomized a second time when exiting via several bore holes arranged in a circular fashion.

Thanks to the innovative design of the nozzle, a spray with a large outlet angle is achieved. This is characterized by an even liquid distribution as well as a fine droplet spectrum with a low specific air consumption. The fineness of the droplet spectrum is decisively influenced by the air/liquid ratio and by the pressure level of the two flow rates. As a general rule: the higher the air/liquid ratio and the higher the pressure level of atomizing air and liquid is, the finer the droplet spectrum. The large free cross-sections in the nozzle keep the risk of clogging and the maintenance effort to a minimum.

Scheme of the VarioJet nozzle

Application examples of the VarioJet II-3 nozzle

- Gas cooling in small-sized to medium-sized evaporative coolers as well as ducts, e.g. in the cement, lime, glass, metallurgical and steel industries or in power plants

- DeNOx in the cement industry and in power plants

Case study: VarioJet II-3 twin-fluid nozzles in a cement plant

For the layout of gas cooling systems as they are used for example in evaporation coolers or ducts in cement plants the droplet diameter of the injected cooling water is important. The smaller the droplet size the shorter the evaporating distance.

If very fine droplets are required for a complete evaporation of the injected cooling water in small evaporation coolers or ducts often Laval nozzles are chosen.

The nozzles of the new VJ II-3 series can offer considerable savings potential for the required atomizing air volume, as shown in the following example.

At a cement plant gas should be cooled down from 375°C to 320°C inside an duct with 2,2m diameter. At present 4 lances each with one piece Laval nozzle 180.641.1Y.81.00.0 are installed. The max. operation point with together 36 l/min injection of water needs total an amount of 170 m³/h STA atomizing air at 4,8 barg to get a full evaporation.

If the 4 pieces Laval nozzle 180.641.11Y.81.00.0 would be replaced by 4 pieces VJ II-3 nozzle 120.444.1Y.AL.00.0 the atomizing air volume required for complete evaporation of the injected water at the maximum operating point after the same evaporation distance can be reduced to a total amount of 56 m³/h at 3,9 barg. This corresponds to a reduction of the required atomizing air quantity by more than 60%, which means a considerable reduction in energy costs.

The required water pressure of the VJ II-3 120.444.1Y.AL.00.0 is approx. 0,9 bar higher at this operating point compared to the L0 nozzle 180.641.1Y.81.00.0.

Accelerate processes – use potentials

Are you also interested in improving the performance of your gas cooling or denitrification? By replacing the existing nozzle lances with nozzles of our new VarioJet series VJ II-3, accelerated heat and mass transfer processes can be achieved.

Besides the droplet size, other parameters play an important role:

- Optimum distribution of the injected water quantity over the cross-section of the evaporative cooler

- Optimization of the gas flow e.g. through perforated or baffle plates

With simulations by means of CFD (Computational Fluid Dynamics) Lechler shows you the intelligent way to the optimal nozzle allocation and supports you to use the potential of your evaporative cooler optimally.