For better air: Scrubber with Lechler nozzles and droplet separators

From January 1st 2020, the IMO (International Maritime Organization) regulation requires all ships on the high seas to use marine fuel with a maximum sulphur content of 0.5% (currently permitted: 3.5%). This is intended to further reduce air pollutant emissions.

This measure is necessary in order to achieve a greatly improved level of environmental protection, as heavy fuel oil (HFO) is usually used on the high seas. Through the use of heavy oil, the approximately 50,000 ocean-going vessels of the international merchant fleet are responsible for 13 percent of global emissions of sulphur oxides (SOx) and 15 percent of nitrogen oxides (NOx). The so-called Global Sulphur Limit, also known as Sulphur Cap, must now be observed worldwide from 2020.

Scrubbers with nozzles and droplet separators reduce emissions

The installation of an exhaust gas purification system (scrubber) during the construction of a new ship or as a retrofit is one way of reducing emissions. Scrubbers are equipped with droplet separators and nozzles. Put simply, the exhaust gases go through a chemical process (gas scrubbing) in which a gas stream is brought into contact with a liquid stream and the pollutants are washed out as far as possible. For the products in the scrubber, this process means maximum material stress, since salty seawater is used as the medium. With success: according to the manufacturer's specifications, sulphur oxides are separated almost 100%. The purified exhaust gases produced by the scrubber produce approximately the same exhaust gas values as low-sulphur marine diesel, which, however, has a considerably higher price.

In the still relatively young market of exhaust gas purification by scrubbers in the marine environment, Lechler has the special position that droplet separators and the corresponding nozzles for gas scrubbing come from one nozzle manufacturer and thus from one source. Lechler is thus making a major contribution today and in the future to ensuring that the IMO regulations can be complied with.

Application examples

Applications in merchant shipping

Nozzles and droplet separators for wet scrubbers

Exhaust gases are desulphurised using full-cone nozzles and the media salt and fresh water. Ideally, nozzles from the 403, 405 and 421 series are used.

Highly efficient droplet separators reduce the emission values from the stack. Here, droplet separators for vertical inflow are used above all.

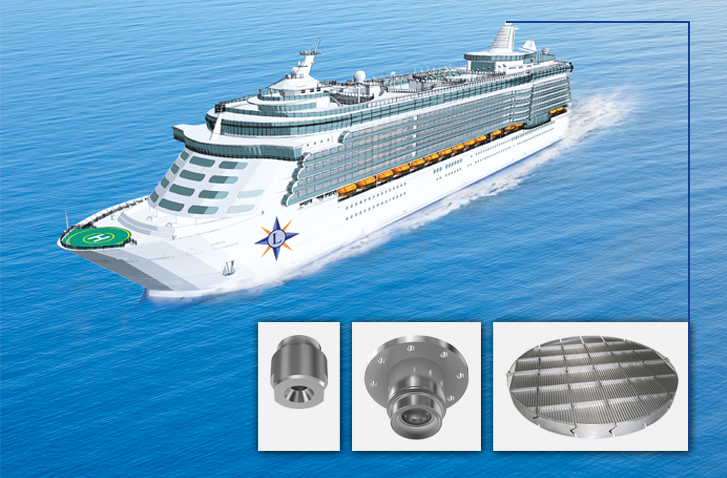

Applications for cruise ships

Nozzles for exhaust gas cleaning (scrubber) and for cleaning droplet separators

Exhaust gases are desulphurised using full-cone nozzles and the media salt and fresh water. Ideally, nozzles of the series 403, 405 and 421 are used.

During the absorption process, droplets can be carried along in the gas stream. These droplets are optimally removed from the gas stream by Lechler's vertically approached droplet separators.

For cleaning the droplet separators, full-cone nozzles of the 490 series are available.

Nozzles for scrubbers and droplet separators

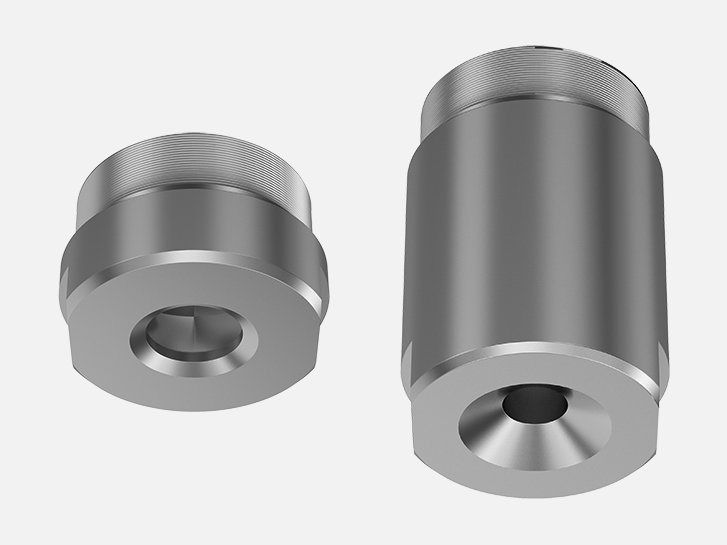

Axial-flow full cone nozzle for scrubbers, series 403

Very uniform spray pattern.

Applications:

- Cleaning and washing processes in exhaust gas cleaning systems (SOx reduction)

- Cooling of gaseous fluids and solids

- Spraying over packings

Axial-flow full cone nozzle for scrubbers, series 405

Particularly uniform full cone atomization.

Applications:

- Cleaning and washing processes in exhaust gas cleaning systems (SOx reduction)

- Cooling of gaseous fluids and solids

Axial-flow full cone nozzle for scrubbers, series 419 "FreeFlow"

Particularly insensitive to clogging due to very large free cross-sections. Stable spray angles. Uniform full cone atomization.

Applications:

- Cleaning and washing processes in exhaust gas cleaning systems (SOx reduction)

- Gas washing

- Spraying over packings

- Dust control

- Absorption

Axial-flow full cone nozzle for scrubbers, series 421

Uniform full cone atomization, high flow rates.

Applications:

- Cleaning and washing processes in exhaust gas cleaning systems (SOx reduction)

- Surface sprinkler system

- Cooling and purification of gases

- Water recooling

- Column sprinkling and improvement of chemical reactions by surface enlargement

Tangential-flow full cone nozzle, series 422/423

Tangentially arranged liquid supply. Without swirl inserts. Non-clogging. Stable spray angle. Uniform atomization.

Applications:

- Cleaning and washing processes such as windscreen washing, ABC protection, droplet separator washing

- Foam control

- Cooling of gaseous fluids and solids

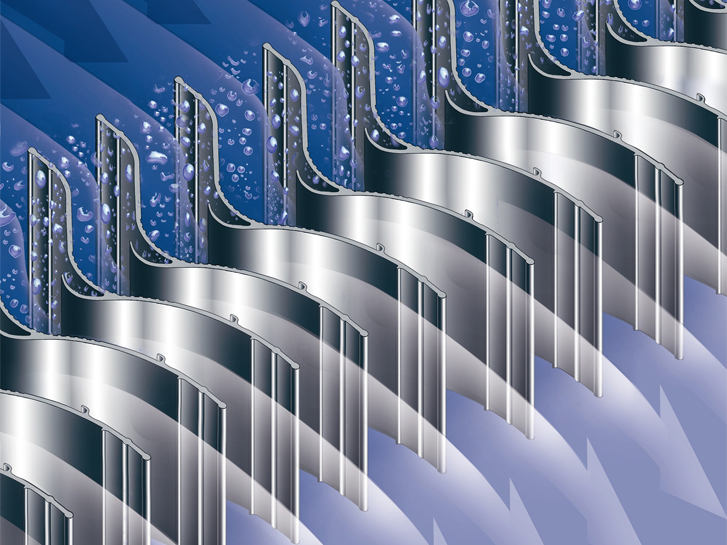

Lechler Droplet Separator Systems on ships

Modular, compact, combinable and efficient. The different Lechler Droplet Separator Systems can be combined with each other, depending on individual requirements in relation to efficiency and space.

Applications:

- Exhaust gas cleaning in wet scrubbers

- Protection of downstream systems

- Operating cost reduction