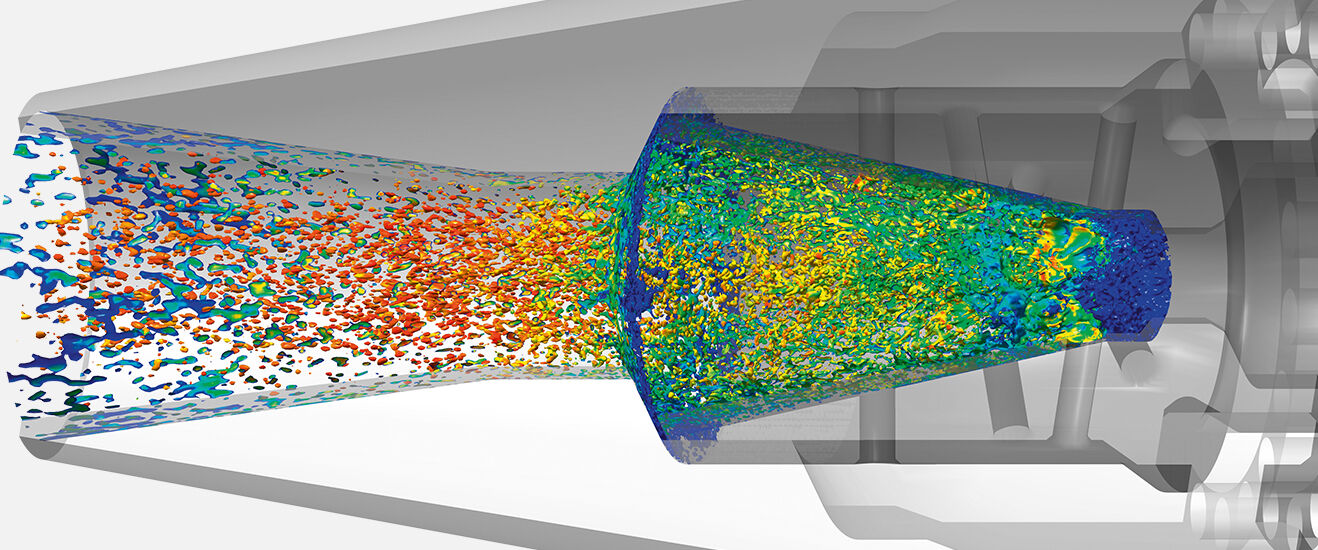

Computational Fluid Dynamics (CFD): Expecting perfection.

A perfect nozzle use is mathematically calculable. For simple geometries such as a straight piece of pipe, the flow state is still relatively easy to calculate using paper, pencil and calculator. If there is just a slight curve, this is then not so easy. Here, Computational Fluid Dynamics (CFD) is required.

Optimize nozzle use and processes using flow simulation

No matter what the spray application, the goal is always to achieve the maximum effect with minimal use of material, spray media and energy. Therefore it is essential to have a detailed understanding of how spray mist is formed and propagated.

We simulate nozzle applications and processes individually for your environment and requirements. Use the flow simulation to optimize your nozzle application. Our professional spray laboratories with specialized measurement technology for practical tests and validations support you in achieving maximum efficiency in your spray application through targeted optimization.

Your benefits

- Maximum efficiency

- when using expensive consumables

- in the geometric measurement of the entire spray process

- Targeted optimisation

- of the choice of nozzles

- of the nozzle operating point (considering the pumps, compressor and flowers)

- of the liquid distribution

- of the droplet sizes

- of the inflow and outflow of your process gases to the spraying process.

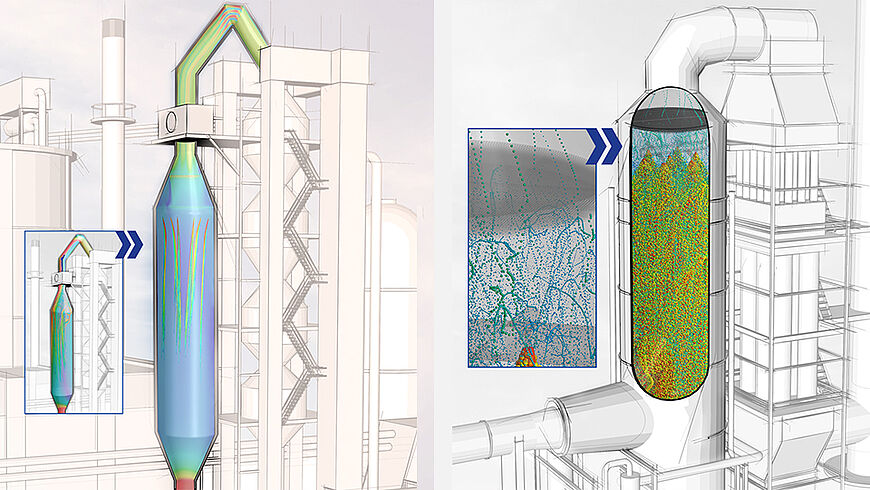

Fluid Dynamics for customer-specific process optimization

Lechler also offers customer specific process optimization for spray processes. Identify spraying processes that have been functioning for years without problems, but which may have a – sometimes considerable – optimization potential.

We explore these spraying processes in our process simulations without intervening in ongoing production. This makes it possible to test different settings and evaluate their effects on the overall result.

Your benefits

- Identification of optimisation potentials

- Virtual evaluation of individual measures

- Risk-free, virtual trials

- Time-saving

- Identification of potential savings

- Clear amortisation analysis

Contact