Test results: The IDTA in facts and figures.

Field tests

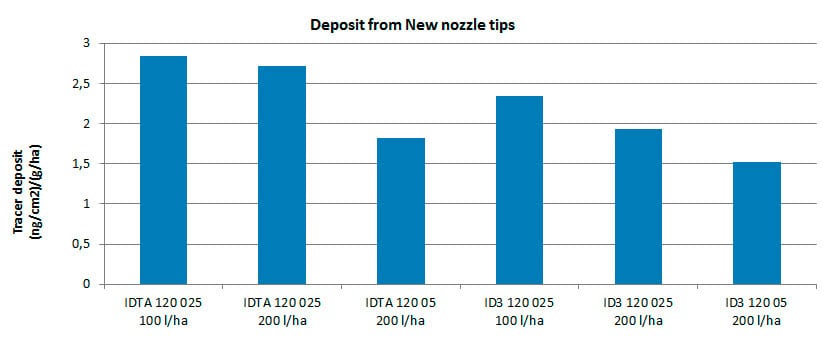

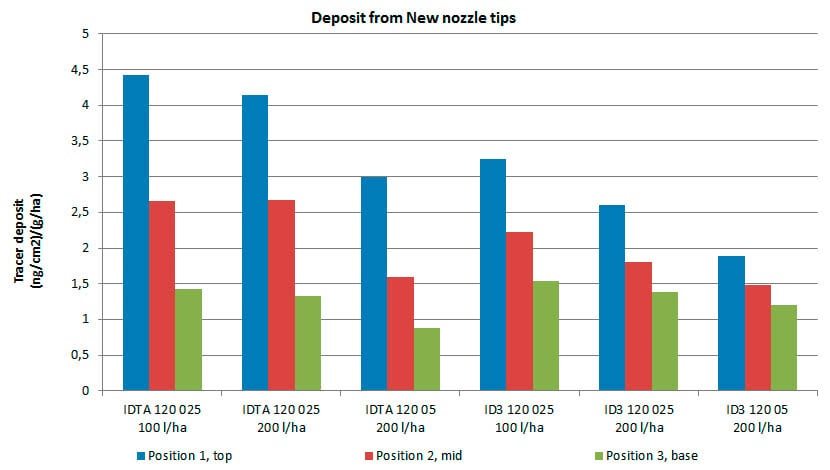

Deposition in winter wheat (Syngenta)

Trial was conducted in winter wheat, growth stage 37 (BBCH). The tracer was Helios 500 SC. Whole plants were taken after spraying and cut into 3 sections:

| Nozzle comparison in winter wheat, BBCH 37 with different speeds and application rates

|

Deposition of IDTA 120-025C/05C compared with ID 120-025/05 | Deposition of IDTA 120-025C/05C compared with ID 120-025/05 |

IDTA achieves up to 17 % better overall deposition compared with ID3. |

IDTA achieves up to 50 % higher deposition in the upper third compared with ID3. |

Field test with vertical target surfaces

Field test was conducted with an Amazone sprayer UF 1201 equipped with a 15 m boom to investigate deposition on vertical target surfaces. Deposition on the front and back sides was analyzed for different nozzle types and forward speeds. Evaluation of the water-sensitive paper was performed with “DepositScan”.

Meteorological conditions:

- Rel. humidity 50 %

- Temperature 23 °C

- No wind

Water-sensitive paper for vertical deposition test

Comparison of different nozzle types on vertical target surfaces

| Type | Lechler ID 120-03 (ID3) | Lechler IDTA 120-03 | Competitor |

| Pressure | 5 bar | 5 bar | 5 bar |

| Speed | 12 km/h | 12 km/h | 12 km/h |

| Düse |  |  | |

Deposit towards front Coverage in % + Droplet number/cm² |  |  |

|

Deposit towards back Coverage in % + Droplet number/cm² |  |  |

|

IDTA air injector double flat fan nozzles achieve significant better deposition on vertical target surfaces compared with an standard air-injector flat spray nozzle (ID3). The nozzles provide up to 3 times better coverage in travel direction.

IDTA in combination with other nozzles

Combinations (JKI approvals pending) | Comparison with air-injector flat spray nozzle (ID3) on vertical target surface |

Mixed setting in the center of the boom with IDTA and ID3 to avoid spraying onto frame and other parts of the sprayer. | Double total coverage |

Border spraying of IDTA with IS 80 possible thanks to same effective spray width of the two patterns of IDTA. | Significantly higher deposition on target to the front and back |

More uniform coverage to the front and back |