Nozzles for every pickling line

We have put together an overview of our nozzles, which are most frequently used in pickling lines. Our experts will be pleased to develop a nozzle solution for your specific requirements. We are also pleased to find individual and innovative special solutions with you.

Nozzle types overview

Flat fan nozzles series 632/633

- Standard design with high-precision spray angle

- Exact flow rate; extremely narrow spray depth

- Parabolic distribution of liquid ensures that spray pipes equipped with these nozzles show an extremely uniform total liquid distribution

- Conical, self-sealing thread connection

- Spray heads design very easy by connecting threads of the nozzles

- Complete product range available at short notice thanks to modular design

- Applications: cleaning, pickling, coating, surface treatment, rinsing

Flat fan nozzles series 621

- Parabolic distribution of liquid

- Applications: cleaning, pickling, surface treatment, rinsing

Flat fan nozzles series 625

- Parabolic distribution of liquid

- Headers, equipped with these nozzles, show a highly uniform total distribution of liquids, even at different installation heights and centers

- Applications: cleaning, pickling, surface treatment, rinsing

Flat fan nozzles for retaining nuts series 652

- Assembly with retaining nut

- Easy nozzle changing

- Simple jet alignment

- Parabolic distribution of liquid

- Spray pipes equipped with these nozzles show an extremely uniform total liquid distribution

- Applications: cleaning, surface treatment, pickling, rinsing

Flat fan dove-tail nozzles series 660

- Assembly with retaining nut

- Automatic jet alignment due to dovetail guide

- Stable spray angle

- Parabolic distribution of liquid

- Spray pipes with these nozzles show an extremely uniform total liquid distribution.

- Applications: cleaning, pickling, coating, rinsing

Flat fan dovetail nozzles series 664/665

- Assembly with retaining nut

- Automatic jet alignment due to dovetail guide

- Stable spray angle

- Parabolic distribution of liquid

- Spray pipes with these nozzles show an extremely uniform total liquid distribution

- Applications: cleaning, pickling, coating, rinsing

Flat fan dovetail nozzles series 669

- Spray pipes with these nozzles show an extremely uniform total liquid distribution

- Applications: cleaning, pickling, coating, rinsing

Tongue-type nozzles series 686

- Wide flat fan with a sharply delimited jet pattern

- Non-clogging

- Applications: cleaning, pickling, rinsing, requiring powerful and concentrated water jets

Tongue-type nozzles series 688/689

- Hard, sharp fl at fan, narrowly delimited jet pattern

- <Non-clogging </li>

- Applications: cleaning, pickling, rinsing, cross spray, requiring powerful and concentrated water jets

Tongue-type nozzles with dovetail series 686.XXX.WW.08

- Wide, sharply defined flat fan pattern

- Non-clogging

- Automatic jet alignment due to dovetail guide

- Applications: pickling, rinsing

Tongue-type nozzles with dovetail series 686.XXX.WW.15

- Wide, sharply defined flat fan pattern

- Non-clogging

- Automatic jet alignment due to dovetail guide

- Applications: pickling, rinsing

Tongue-type nozzles with dovetail series 686.XXX.WW.09

- Wide, sharply defined flat fan pattern

- Non-clogging

- Automatic jet alignment due to dovetail guide

- Captive cap nut for easy maintenance

- Applications: pickling, rinsing

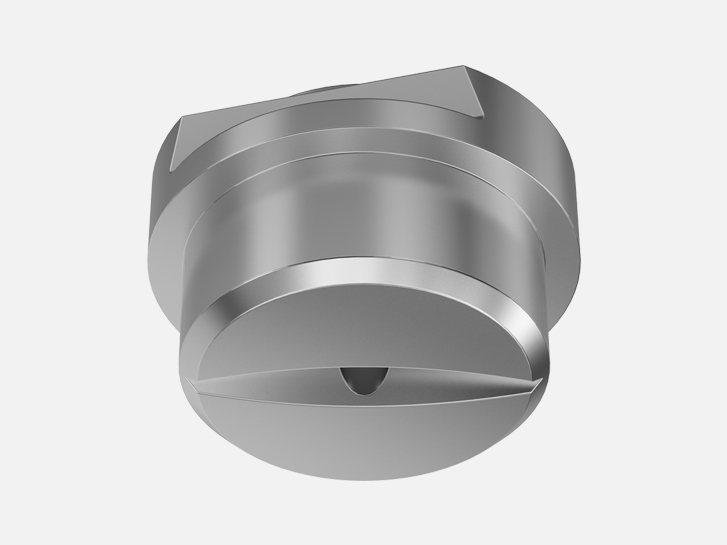

Axial-flow full cone nozzles series 490/491 – stainless steel version

- Non-clogging nozzle design

- Stable spray angle

- Particularly even liquid distribution

- Applications: pickling, Surface treatment, rinsing, acid fume scrubbing

Axial-flow full cone nozzles series 460/461 – PVDF version

- Very uniform spray pattern

- Large free cross-sections, due to optimized x-style swirl insert

- Applications: pickling, Surface treatment, rinsing, acid fume scrubbing

Multi-channel flat fan nozzles for air – Whisperblast series 600.130 / 600.493 / 600.562

- Highly effcient air stream, acting upon areas

- Reduced noise levels

- Low air consumption

- Applications: blowing off and blowing out, cleaning, drying, cooling, conveying with air

Flat fan nozzles for air or saturated steam series 679

- Particularly wide-angle, powerful air jet

- Assembling with retaining nut

- Easy nozzle changing

- Simple jet alignment

- Applications: blowing off liquids, cooling, reheating, drying

Multi-channel round jet nozzles for air series 600.326

- Powerful air jet, producing punctiform impact patterns

- Low noise level

- Low air consumption

- Applications: targeted blowing out and blowing off with compressed air

Eductor nozzles series 500.262/500.428

- No risk of blockage thanks to the large cross sections from 2.0 to 10.0 bar

- Application: tTank mixing, liquid circulation, preventing sedimentation

Tangential nozzles series 300.185

- Very homogeneous and stable hollow cone spray pattern

- Not prone to clogging due to tangential design

- Applications: acid regeneration

Spray headers

Lechler supplies spray headers for spraying applications in processing lines for strips and wire, such as

- Washing

- Pickling acid spraying

- Rinsing

- Cooling

- Strip edge drying