Pneumatic atomization

The term pneumatic nozzle refers to the mixture of two materials. Mostly water and air but this does not mean that it is not possible to use two liquids for atomization.

Pneumatic nozzles – als known as twin-fluid nozzles – are used in a variety of applications. The individual pneumatic nozzles series can be seperated into internal and external mixing nozzle types. Gas and liquid are mixed either inside or outside the nozzle. Depending on the nozzle design, the liquid is autonomously sucked into the nozzle or it is applied under pressure. Depending on the geometry of the nozzle outlet, different spray patterns are created.

Pneumatic nozzles are ideal for atomizing small quantities of liquid, however it is possible to use them for larger volumes as well. Different flow velocities of gas and liquid inside the nozzle during pneumatic atomization cause compressional waves, which shear the liquid flow and thereby generate very fine droplets. These different relative speeds between gas and liquid are the key for atomizing viscous mediums at low pressures.

Pneumatic nozzles offer a lot of advantages:

- Very fine droplets are generated

- Precise volume flow control possible with consistently good atomization quality

- Hardly any liquid pressure is required to atomize finely

- Substances with a viscosity of up to 1,000 mPa·s can be atomized

Pneumatic atomization

Pneumatic nozzles are capable of generating almost any spray pattern:

- Flat fan

- Full cone

- Hollow cone (very rare)

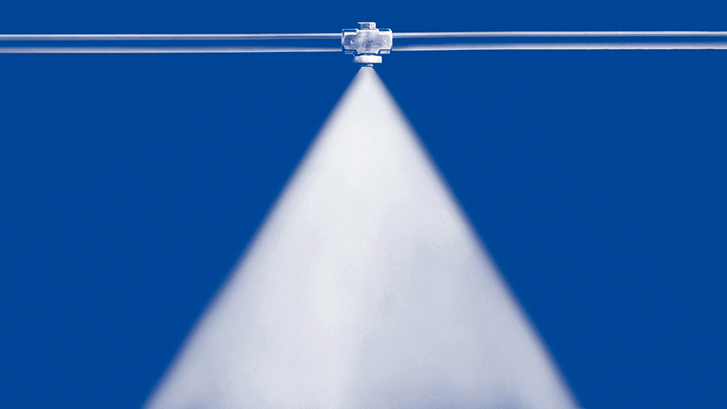

Pneumatic flat spray atomization

Pneumatic flat fan atomizing nozzles produce a flat spray pattern with extremely fine droplets and spray angles up to 80°. These nozzles are particularly suited for applications requiring fine droplets and a wide linear impact.

Application examples: Commodity humidification and cooling, assembly line humidification, various coating tasks.

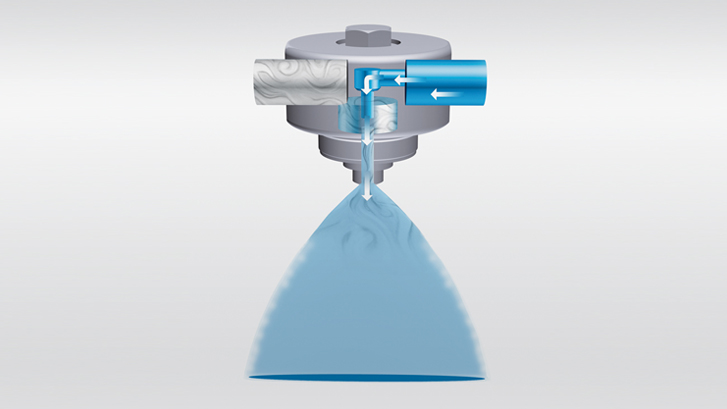

Pneumatic full cone atomization

Full cone pneumatic atomization nozzles are favored in applications which require a circular impact pattern or where a greater coverage is required. Generally, a slim full cone with 20° to 30° spray angle is produced. Wider spray angles can be achieved by using nozzles with multi-orifice outlets.

Application examples: Humidification, cooling, application of viscous media e.g. oils

Mixing of fluids

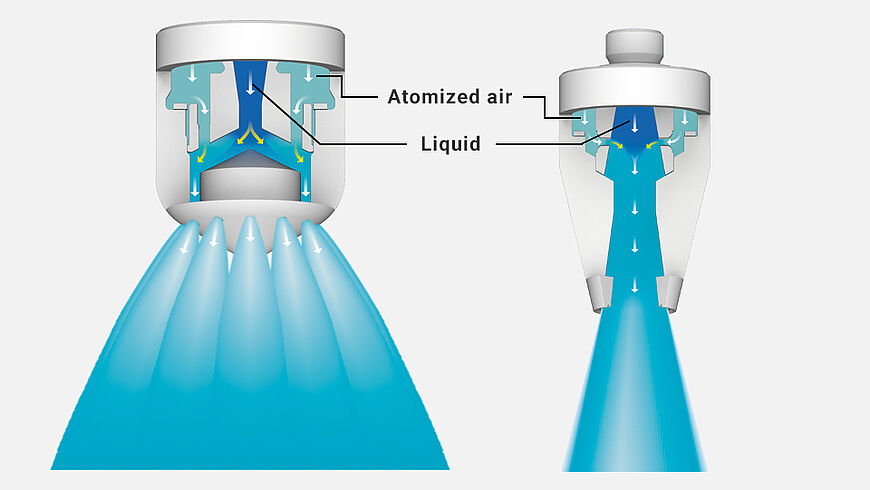

The supply of air or gas provides an additional breaking up of the liquid flow into finest drop particles. This supply and mixing can either take place inside or outside the nozzle.

Inside mixing should be preferred, when water, low viscosity liquids or liquids without solid matter are to be atomized.

Outside mixing is particularly suited for atomizing viscous liquids which are prone to impurities and therefore tend to cause clogging of the nozzle. Low liquid pressures are used with this type of nozzle due to its design.

External mixture

Gas and liquid are mixed after discharged from the nozzles outlet. Liquid leaves the nozzle coaxially through a central aperture. Gas streams are discharged around this aperture and surround the liquid flow. As a result of the high velocity of the gas stream the liquid stream is sheared apart.

External mixing pneumatic nozzles are perfect for atomizing viscous media. However, there are some limitations:

- The spray pattern is limited to a narrow full cone. A flat spray pattern is only possible by the use of two air orifices arranged opposite to each other. These additional air orifices help to create a flat pattern out of a full cone. This priciple is used for nozzles of the series 176 (ViscoMist). The liquid is atomized in two stages:

- The discharged full jet enclosed by air is partially torn apart.

- Two small air orifices at the nozzles spreader head, called “fan air”, create the flat jet pattern.

- For constructional reasons the flow rate is limited. External mixing pneumatic nozzles are therefore rather suitable for atomizing smaller quantities of liquid.

Internal mixture

With internal mixing pneumatic nozzles, the liquid and gas streams are mixed inside the nozzle chamber. Hereby, the compressed air/water mixture expands the spray when exiting the nozzle and thereby produces very fine droplets.

In contrast to the external mix, the spray pattern of the internal mix is much easier to control. In addition, smaller as well as larger quantities of liquid can be atomized.

However, internal mixing nozzles are less suitable for viscous media. In addition, great importance must be attached to the correct choice of air/water mixture. A high pressure differantial is not recommended.

Further information

Spray character

Which (spray) character fits your application and which different spray patterns are available?

Spray CharacterNozzle functions

Explanations of the most important functional and operating data of a nozzle.

Nozzle functionsDroplet separators – Operating principle

Reduce residual pollutant contents and improve process engineering.

Droplet Separators – Functional Principle