A few days before the mandatory implementation, the question arises as to how far ships have already been retrofitted with scrubbers. Unfortunately, no reliable statement can be made at this point in time. But how can exhaust gases actually be cleaned with scrubbers?

Against the background of the IMO regulation coming into force next year, which sets a global sulphur limit of 0.5% for international shipping, the exhaust gas cleaning systems - known as scrubbers - are becoming increasingly important. As a rule, these are wet scrubbers, which require approx. 40 - 50 m³ of seawater per hour per megawatt engine power and alkalinity of the seawater.

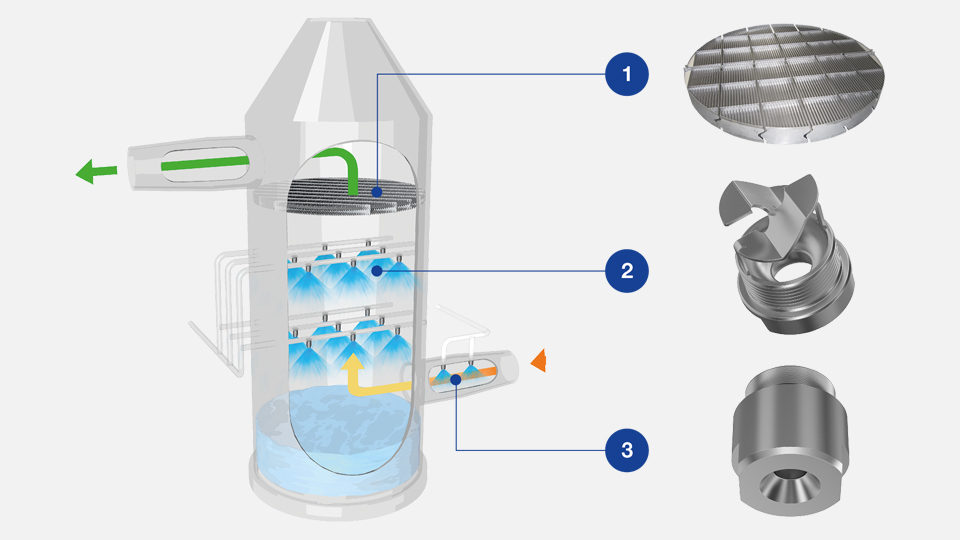

Example for scrubber with a mist eliminator (1), nozzle series 4H5 (2) and nozzle series 405 (3).

Depending on performance requirements, scrubbers measure between two and six meters in diameter and up to ten meters in height. Since space on ships is always limited, the rule is: as large as necessary, as compact and light as possible. Scrubbers are optionally designed as open-loop, closed-loop or hybrid systems. The open-loop system only uses seawater. Closed-Loop uses sea water, which is enriched by adding a basic lye (often caustic soda lye) for the cleaning process. This system therefore works independently of the alkalinity of the seawater present. The hybrid system makes use of the advantages of both systems.

All three types use a coordinated set of nozzles for gas cooling (quench), gas scrubbing (absorber) and a system of mist eliminators for reliable exhaust gas cleaning, particle and mist removal. Simplified, the exhaust gases of the ship engines are passed through the scrubber over several stages and layers. In the Quensche, the exhaust gases, which are several hundred degrees hot, are first cooled to below 80 °C. Gas scrubbing reduces the sulphur content of the exhaust gases by 90 - 95 %. Sulfur dioxide is converted into sulfurous acid by the water flow reacting with it and removed from the gas. Before the cleaned waste gases leave the chimney, mist eliminators bind the residual liquid contained in the gas so that no sulphurous acid is emitted.

Overview