Efficiently irrigate, sprinkle and humidify with Lechler nozzles

When the sun sends its hot rays from the sky in the summer months, one or the other sun-seeker may enjoy it – but everyone is grateful for a cool down. Especially in agriculture, which has to struggle more and more with dry periods, but also in certain industrial sectors that involve dusty or heat-intensive environmental conditions, irrigation, sprinkling or humidification with water is necessary or even vital.

Lechler nozzles are the optimum solution for agriculture as well as for various industrial sectors struggling with the above-mentioned problems. Used for specific applications, they enable efficient irrigation, misting, soaking or particle binding.

Examples in Agriculture

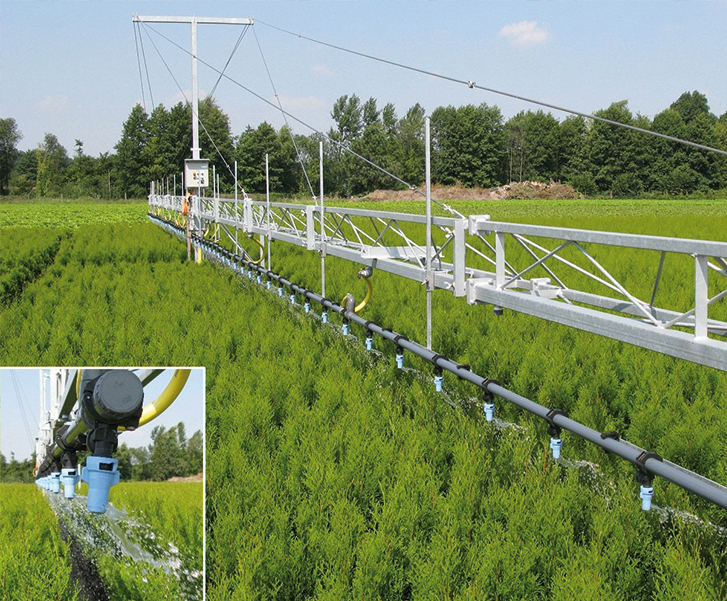

Irrigation booms for greenhouse or outdoor-use

In nurseries, taking care for crops from seed to ready-to-sell plants is a whole-year job. But especially in the summer months, controlling the climate and water supply for the benefit of the plants is quite crucial. With so-called irrigation booms, the plants are irrigated several times a day with very equal distribution for homogenous growth. If needed, also nutrients are applied at the same time.

Depending on the size of the plant and the need for water, our customers use for this purpose

- Flat fan nozzles series 652,

- ID3 injector nozzles to avoid losses and reduce the "impact" on the substrate

- for high water volumes FD nozzles.

Cow Cooling – Avoiding heat stress in the barn

We as humans get in "heat stress" at high summer temperatures and/or high humidity, which challenges our body. For cows as "suppliers" of milk, cream, yogurt, the level of heat stress is much lower than for us, because their metabolism is working hard to convert grass, grain or corn into milk. This generates a lot of heat, which cows can poorly dissipate through their skin (leather).

Cows feel comfortable at -5 to +20° C; above these temperatures stress begins for them and we can use Lechler nozzles to ensure that they are still feeling well – also in the interests of animal welfare. The consequences of heat stress are less feed intake, less movement of the animals and also a lower production of milk, with higher costs for the farmer.

In addition to large fans to cool the animals, nozzles are used more and more to increase the cooling effect.

Cow showers – always cool cows

Cow showers – also called low-pressure systems – are optimally suited to lower the body temperature of the cows. It is important to ensure air movement with cross-ventilation in the barn or to install the showers outdoors, otherwise there is a risk of a "tropical climate" with very high humidity and additional stress. For a cow shower, coarse drops – similar to rain – are optimal because they reduce the increase in humidity and penetrate better into the cow's skin. By using a timer, a cow shower can be operated at intervals while reducing water consumption at the same time.

As a cow shower in walk-waly, in waiting areas in front of the milking parlor or outdoors, we recommend

- several full-cone nozzles of series 460 in polypropylene or

- nozzles of series 490 in brass/stainless steel to shower several animals at the same time and avoid rank fights.

Soaking – cooling during feeding

To cool cows during feeding – so-called "soaking" – we recommend to mount the nozzles above the gates - out of reach of the cows.

Therefore we recommend flood nozzles

- series FT 140 in polypropylene or

- series 686 in stainless steel/brass

installed on the pipe at a distance of 1.5 – 2 m. Important is to run them at low pressure with coarse drops to achieve a good cooling effect to the animals while eating. Ideally, fans support the effect and a timer controls the intervals to reduce water consumption.

Examples in General Industry

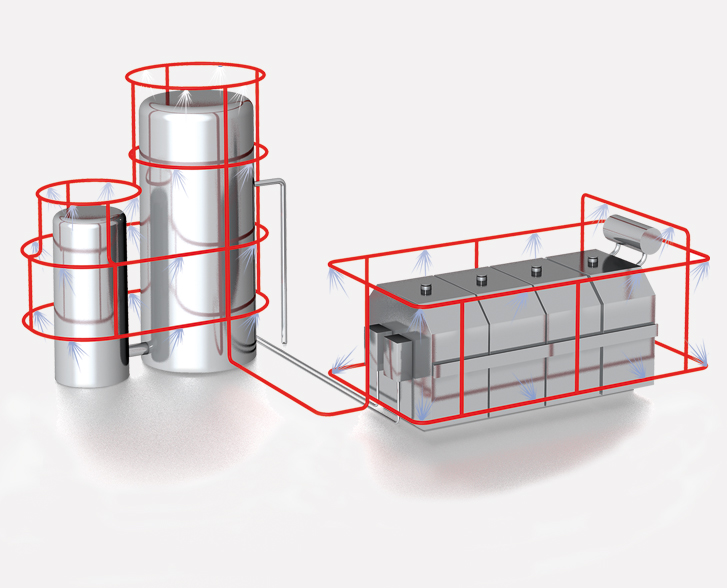

Tank sprinkling/spraying/cooling and preventive fire protection

The purpose of tank sprinkling/spraying/cooling is to protect tanks or other containers from impermissible heating during a fire. For effective protection of a tank, it must be sprayed with water on all sides or covered with an even film of water. This also serves as preventive fire protection. Lechler offers nozzle solutions for optimum wetting of various types of containers of all sizes – whether upright/lying cylinder tanks, spherical containers or reaction towers.

Applicable nozzles:

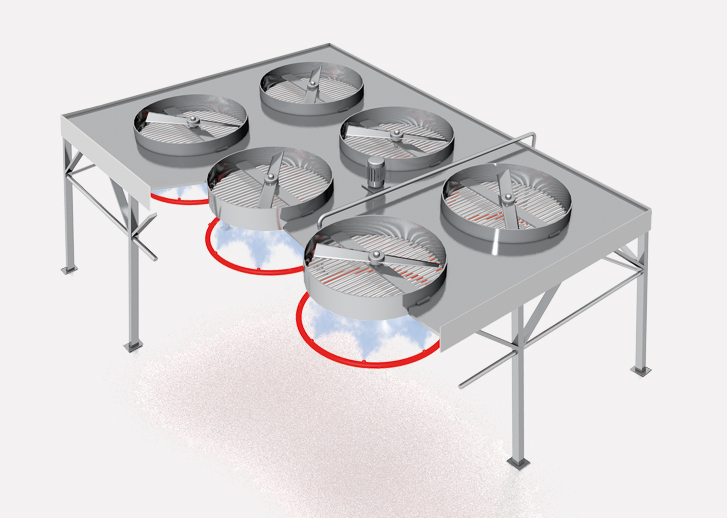

Air humidification and cooling

From microelectronics to packaging, there are many industries where air humidity has a major impact on the quality of manufactured products. Nozzles are used for air cooling and humidification to increase the efficiency of heat exchangers, or the nozzles are installed in air conditioning systems for humidification and cooling. In addition, nozzle technology can be used, for example, to directly humidify the air in production halls or storage rooms.

Applicable nozzles:

Dust control

In many areas of processing, dust generation and the associated stress for humans, animals and technology play a major role. For dust control, fine water droplets are used which bind airborne dust particles, thus giving them a higher weight and causing them to sink or stick. The size of the water droplets, which can be optimized by selecting the appropriate nozzle, is decisive for effective dust control with atomized water. It is also possible to reduce dust formation by moistening the material. Efficient, cost-effective solutions are required in sectors such as the automotive industry, the chemical industry, the food and beverage industry, the pharmaceutical and cosmetics industry, the pulp and paper industry, as well as in coal mining, stone quarries and waste disposal sites.

Applicable nozzles:

- Low-pressure single-fluid nozzles (hollow cone nozzles and full cone nozzles)

- High-pressure single-fluid nozzles

- Pneumatic atomizing nozzles