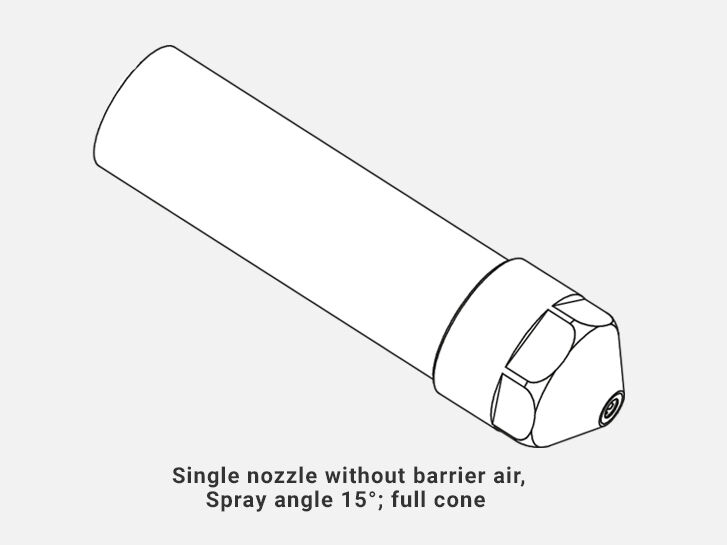

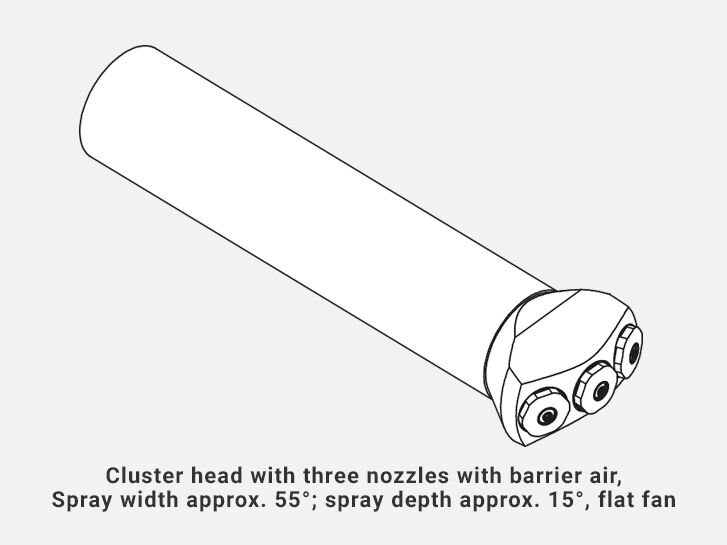

1AW Nozzle Lances

Special twin-fluid nozzles for SCR applications.

The Lechler 1AW nozzle works according to a newly developed and patented atomization principle. It divides the supplied atomizing air into a primary and secondary air flow. Thanks to the specific inflow geometry, the secondary air exits through an annular gap causing a very fine atomization in the edge region of the spray. This twin-fluid nozzle enables finest droplet spectra and shortest evaporation distances while also allowing very good controllability of the flow rate. Cluster heads designed specifically for these nozzles multiply the flow rates and adapt the spray pattern to the requirements at the point of injection.