Cleaning efficiency class 1

Reliable rinsing of tanks and equipment installations

These static spray balls of cleaning efficiency class 1 are designed for hygienic rinsing with a flow rate of 14 to 460 l/min at 2 bar, as is frequently required in the food and beverage industry.

In addition to liquid media, the static spray balls can also be operated with media such as steam and air and therefore are especially suitable for SIP cleaning (Sterilization in Place).

Lechler products in this class are also designed for operation at higher temperatures and guarantee high process reliability.

Features

Nozzles of cleaning efficiency class 1

Series 527

The 3A certification also makes the products of series 527 suitable for areas with the highest of hygiene requirements. They clean with powerful solid jets, have a high surface quality and are also reliably resistant to high temperatures.

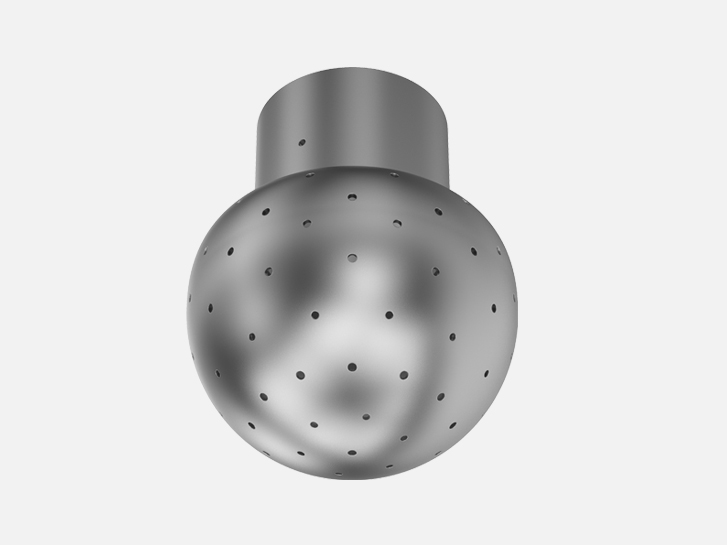

Series 5B2/5B3 "RinseClean"

The spray ball design has proven itself in many applications. It can be used in areas with high hygienic requirements and high temperatures. Our "RinseClean" spray ball is available with various slip-on connections, as well as in threaded or welded versions.

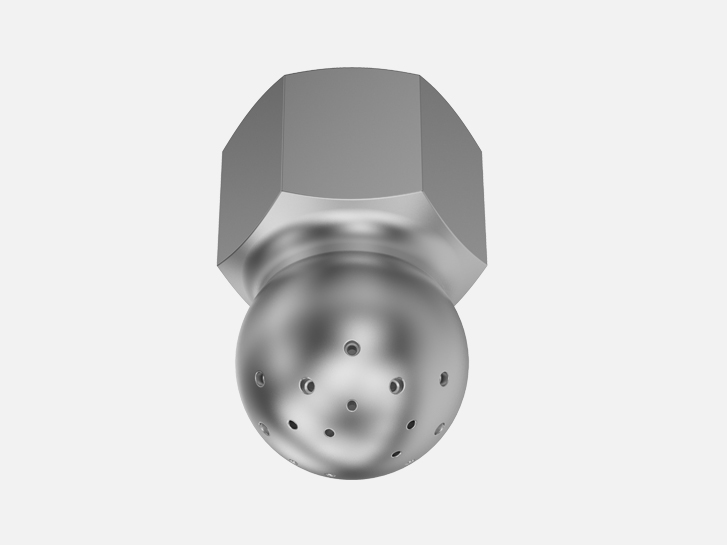

Series 540/541

The robust series 540/541 have a threaded connection and an especially compact design. They can also be used at high temperatures as well as for the output of steam and air.