Air Quality Control Systems:

Innovative solutions for a trending market

Significant changes have been ongoing in the steel industry for many years now and therefore the industry is constantly confronted with major challenges. At Lechler we know a lot about the steel industry thanks to our extensive

practical experience. Due to to this knowledge we can provide the right answers to a wide range of applications with our nozzles and system solutions.

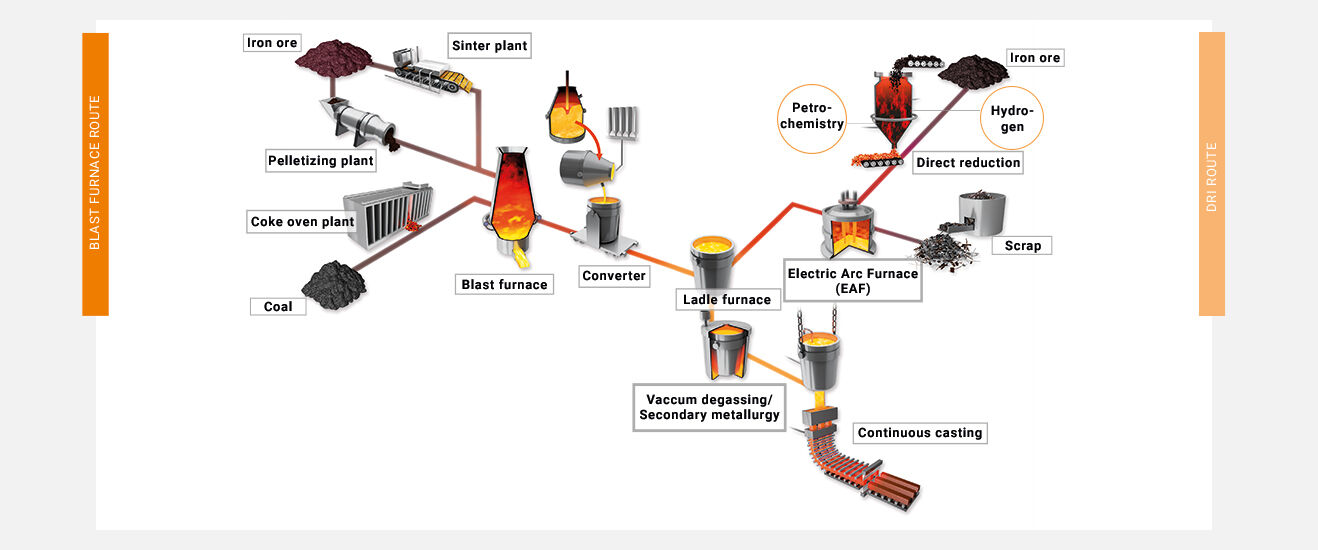

Lechler nozzles have been an established part of the various steelmaking processes for many years:

- in the conventional blast furnace route

- in the electric arc route

- in the modern direct reduction process

- in the rolling mills

Lechler nozzles and droplet separators make a crucial contribution to ensuring the desired quality and efficient production as well as environmental standards in all process steps.

Application areas of Lechler nozzles in the steel industry

Lechler nozzles are used in almost all steps of steel production. In addition, also in the upstream processes such as those in the petrochemical industry and hydrogen technology for direct reduction processes.

Choosing the right nozzle

Best results are achieved in gas cooling and conditioning processes only when detailed knowledge of process-specific requirements is available to assist in the choice of nozzles.

Our portfolio includes, among others, the following nozzles, nozzle lances and systems. We will be happy to provide you with comprehensive advice taking your system and the applications you require into account.

Spillback nozzles – Atomization without compressed air

The liquid is atomized as a fine hollow cone. A uniform and fine liquid atomization is achieved across the entire control range.

VarioJet nozzles – Twin-fluid nozzles with low air consumption despite large outlet angle

The innovative design of the nozzle achieves a spray with a large outlet angle. This is characterised by an uniform liquid distribution as well as a fine droplet spectrum with a low specific air consumption.

Laval nozzles – Twin-fluid nozzles for a wide droplet spectrum in special applications

The large free cross-sections of the nozzle also allow atomization of viscous or solid-laden liquids.

Nozzle lances – Highest spraying accuracy in the flue gas duct

Lechler nozzle lances ensure optimal spray placement and alignment in flue gas ducts. The nozzles themselves have a low-maintenance design and can be cleaned or exchanged with minimal effort. Lechler Online Cleaning (LOC) helps cleaning the nozzle lances at low cost.

VarioCool and VarioClean Gas Cooling/ Conditioning Systems – For a perfectly tailored solution

Our valve skid units for regulating the flow rates of water and atomizing air are individual customer-specific solutions. Based on the requirements in each case, our first step is to design an overall concept and select the best components in order to create a perfectly tailored solution.

We also offer solutions for the following topics

Contact

Do you have any questions about our nozzles and system solutions? Then please feel free to contact us: