TwinAbsorb and TwinAbsorbPRO

Nozzles for wet flue gas desulphurisation

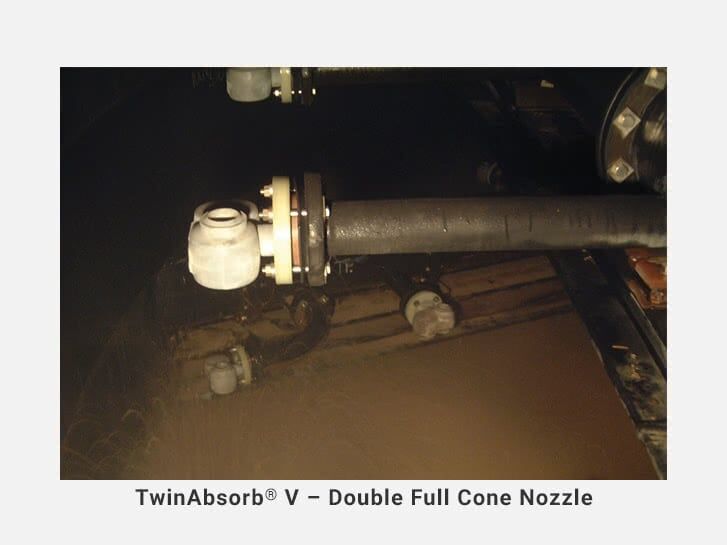

The innovative technology of Lechler TwinAbsorb nozzles ensure for an efficient flue gas cleaning and reliable SO2 separation. Their improved efficiency, the reduced operating costs together with the low maintenance costs make TwinAbsorb nozzles, from a process technology as well as economical consideration, the first choice for power plant operators, but also for operators of waste-to energy plants with wet flue gas cleaning processes.

The patented TwinAbsorbPRO series generates variable asymmetrical spray patterns. This additional feature ensures that the lime suspension is distributed into the scrubber as efficiently as possible, which means the largest possible reaction surface is permanently available to the absorption process. Furthermore, fixtures, wall areas and pipelines can be protected much better against wear. In addition to the proven properties of the TwinAbsorb series to stimulate the desulfurization/absorption process specifically by turbulence-generating counter-rotating rotation of the spray cones, intensive secondary atomization of the spray, as well as higher differential velocities between gas and spray medium, now the variable spray patterns generate further prerequisites for considerable process engineering advantages while at the same time reducing operating and maintenance costs.